Black steel pipes-12 things you should know

- Share

- publisher

- Tianjin Yuantai Derun Steel Pipe Manufacturing Group Ltd.

- Issue Time

- Dec 25,2023

Summary

Black steel pipe is a very common pipe product with a wide range of applications, but do you want to learn more about black steel pipes? Now let's take you to a deeper understanding of it.

Black steel pipe is a very common pipe product with a wide range of applications, but do you want to learn more about black steel pipes? Now let's take you to a deeper understanding of it.

1.What Is Black Steel Pipe?

Black steel pipe is a type of steel hollow section, usually referring to steel pipes that have just come off the production line without any surface treatment. Because dark iron oxide forms on the surface during the production process, it is called black steel pipe.

Brief History Of Steel Pipe

When we talk about black steel pipes , we ultimately cannot bypass the history and origin of steel pipe production technology. As we all know, there are 2 main types of steel pipes: welded steel pipes and seamless steel pipes. Do you know how the production technology for these two types of pipes evolved? Let's briefly walk you through it.

The production technology of steel pipes originated in the early 19th century and, through development and improvement, gave rise to modern steel pipes.Some people also believe that pipelines first appeared in China over 2000 years ago. Now,the global annual production of steel pipes can reach over 100 million tons.

The development of welded steel pipes began in 1815 with William Murdock's a coal burning lamp system. In 1824, James Russell applied for a patent for an early and famous method of producing metal tubes quickly and inexpensively.

Not long after, Comenius Whitehouse invented a method called butt welding process, which is also the foundation of modern pipeline manufacturing technology.The following is a simple process for manufacturing this type of steel pipe.

In this method, the thin iron sheet is heated and passed through a conical open mold. When the metal passes through the open grinding tool, the edge of the thin iron sheet curls to form a tube shape, which is then welded by a drop hammer. Finally, the two ends of the tube are welded together, and the tube is considered to be made.

In 1832, the roll forming method for welded pipes began to be used in Philadelphia, United States. And on this basis, an upgrade was made. In 1911, John Moon proposed an important innovation based on the Whitehouse method. He invented a continuous production process and manufactured machinery for this process, which can continuously produce steel pipes. This machine was introduced and warmly welcomed by pipeline manufacturing factories. As a result, welded pipelines have been vigorously popularized, and in this process, people have also developed a demand for seamless pipelines.

Seamless pipes are pipes without welds. The initial seamless pipe was made by drilling a hole in the center of a solid cylinder. This method began to develop in the late 19th century. At that time, seamless tubes were the ideal choice for bicycle frames because they had the advantages of being thin-walled, lightweight, but sturdy.

In 1895, the first seamless pipe factory was established, Due to the rise of the automobile manufacturing industry, the demand for gasoline and oil has begun to increase. With the discovery of a large amount of oil reserves, the demand for seamless pipes has also continued to rise, and their applications have become more widespread.

The old-fashioned seamless pipe production method of round rod drilling also has some defects, such as difficulty in finding the center of the circle, low efficiency, and uneven pipelines. In 1888, the round rod drilling method was upgraded again, and this upgrade was also patented.

In the new method, The solid nozzle is cast around the refractory brick core. After cooling, remove the bricks and leave a hole in the middle. From then on, the production technology of seamless steel pipes has been thoroughly improved and developed. The production technology of seamless steel pipes is now very mature.

2.What Are Black Steel Pipes Used For?

When we talk about the application of black steel pipe, you have to understand the composition of the black steel pipe, because the black steel pipe is used in different application scenarios, the use of different types of black steel pipe, the different chemical composition of the black steel pipe, creating a difference in the performance of the black steel pipe, so there is some talk about the chemical composition of the black steel pipe, these components have what effect on the application? The following will take you to understand.

2.1 Chemical composition of black steel pipes

Ferrum (Fe): The main component of black steel pipes. Pure iron is a metallic element with a silver white luster. In addition to conductivity, thermal conductivity, and ductility, iron can also be attracted by magnets and have ferromagnetism.

Carbon (C): The carbon content affects the hardness and strength of steel. Compared to galvanized steel pipes, black steel pipes usually have a higher carbon content.

The carbon content is the dominant factor determining the strength of steel pipes, and the higher the carbon content, the higher the strength of the steel pipe. Generally speaking, the carbon content of low-carbon steel is around 0.1%, medium carbon steel is 0.25%~0.6%, and high carbon steel is 0.6%~1.5%. In low-carbon steel, steel pipes have good weldability and plasticity, but their strength is relatively low; High carbon steel, on the other hand, has high strength and hardness, but poor plasticity and is prone to fracture.

Silicon (Si) :The silicon content is an important factor determining the heat and corrosion resistance of steel pipes. The higher the silicon content, the stronger the heat and corrosion resistance of the steel pipe. Generally speaking, the silicon content is between 0.15% and 0.35%, and whether it is too high or too low can affect the quality and service life of steel pipes.

Manganese (Mn): Manganese is usually added to improve the ductility and formability of steel.

Manganese content is a common strengthening element in steel pipes, which can improve their strength and toughness. The higher the manganese content, the greater the strength and toughness of the steel pipe. However, excessive manganese content can affect the weldability and plasticity of steel pipes.

Sulfur (S): Sulfur exists in trace amounts and can improve processability, but is usually kept at a low level to avoid negative effects on material properties.

Phosphorus (P): Like sulfur, phosphorus exists in trace amounts and can affect the properties of steel.

2.2 Usage of Black Steel Pipes

Water supply and drainage system: Black steel pipes are widely used in fluid transportation scenarios. Black steel pipes are commonly used in water and natural gas supply and discharge systems in residential, commercial, and industrial environments. They are suitable for underground and above ground installations.

Structural support: Black steel pipes are often used for building structural support, especially for building frames and scaffolding, due to their natural strength and toughness advantages. They enhance the strength and stability of steel structures.

Fire sprinkler systems: Due to its durability and fire resistance, black steel pipes are often used for automatic sprinkler fire extinguishing in residential and commercial buildings. Many common fire protection pipelines use black steel pipes.

Mechanical and automotive applications: Black steel pipes are used in various mechanical and automotive components, undoubtedly greatly increasing the strength and reliability of machinery and automobiles.

Oil and gas pipelines: In some cases, black steel pipes are used in specific applications in the oil and gas pipeline industry that may not require galvanizing.

3.Black Steel Pipe Characteristic

Has good corrosion resistance:Black steel pipe is subjected to oxidation reaction on the surface will generate black iron oxide, forming a layer of protective layer is not easy to fall off, has excellent corrosion resistance.

Has good mechanical properties: stronger tensile, compressive, and bending abilities.black steel pipes undergo processing techniques such as hot rolling and cold drawing, resulting in a smooth surface, high strength, and strong bending resistance, making them suitable for situations that withstand heavy loads.

Has good processing performance: easy to weld, drill, connect, thread, expand, bend, and so on.Due to the soft material and good processability of black steel pipes, they can undergo various surface treatments to make their appearance more beautiful.

Has good cost-effectiveness: the cost of black steel pipes is low, and the production cycle is fast.Taking the Yuantai Derun black high-frequency welded steel pipe production line as an example, we have 65 such production lines that will quickly complete your order tasks.

4.Black Steel Pipe Grade and Standard

When people talk about the steel grade of black steel pipes, they have to talk about world standard pipeline standards such as ASTM, API 5L, API 5CT, etc. Among them, well-known standards such as ASTM A53 pipe (black steel pipe astm a53) 、ASTM A106 pipe and black steel pipe bs1387 are common black steel pipes in pipeline engineering.

Common grades of black steel pipes include Q195, Q215, Q235, Q355, ASTM A53, ASTM A106, Gr A. Gr B. Gr C. S235, S275, S420, SS400, AS1163 C250, C350, C450, etc

Black Steel Pipe Standard

There are many standards for black steel pipes, among which the most common are ASTM standards, GB standards, EN standards, AS standards, and so on.Steel Hollow section: ASTM A500/A501,EN10219/10210,JIS G3466,GB/T6728/3094/3091,AS1163,CSA G40.20/G40.21

5.Black Steel Pipe VS Galvanized Steel Pipe

Simply put, black steel pipes are the "mother" of galvanized steel pipes. Without black steel pipes, there would be no galvanized steel pipes. Because the base material of galvanized steel pipes before galvanizing treatment is black steel pipes. The differences between the two types of steel pipes can be simply summarized as the following points.

5.1 In terms of corrosion resistance, black steel pipes are not covered with coatings and have relatively weak corrosion resistance. The galvanized steel pipe has a layer of galvanized coating on its surface, greatly enhancing its corrosion resistance.

5.2 In terms of cost, the cost of galvanized steel pipes is higher than that of black steel pipes.

5.3 In terms of color and appearance, the surface of galvanized steel pipes is silver white, while the surface of black steel pipes is black gray.

6.Black Steel Pipe VS Carbon Steel Pipe

Black steel pipe is just a type of carbon steel pipe, specifically referring to steel pipes with exposed surfaces without coatings.

In terms of scope, carbon steel pipes can include special coated steel pipes such as black steel pipes, galvanized steel pipes, and zinc aluminum magnesium coated steel pipes,seamless steel pipe,etc.

From a chemical composition perspective, carbon steel pipes can be divided into low-carbon steel pipes, medium carbon steel pipes, and high carbon steel pipes. Black steel pipes generally do not emphasize carbon content. In terms of usage, there is no doubt that carbon steel pipes have a wider range of applications. In terms of corrosion resistance, the black iron oxide protective layer formed by black steel pipes is more corrosion-resistant in the same environment, while carbon steel pipes are different.

7.Black Steel Pipe VS Black Iron Pipe

Black steel pipe and black iron pipe are both a type of steel pipe without coating treatment. It's just a bit different in terms of terminology. Black iron pipe is a type of iron pipe, and its ductility is slightly better than that of black steel pipe. Black steel pipes have higher hardness and other aspects because the carbon content of black iron pipes is lower. There is no significant difference between the two.

8.How To Protect Black Steel Pipe?

The common methods for protecting black steel pipes include oiling, coating, painting, galvanizing, anti-corrosion and insulation, etc.

9.Types Of Black Steel Pipe

There are only two types of black steel pipes: seamless black steel pipes and welded steel pipes. Seamless steel pipes are divided into three categories: hot-rolled seamless steel pipes, cold-rolled seamless steel pipes, and cold-drawn seamless steel pipes. Welded steel pipes are divided into ERW pipes, LSAW pipes, SSAW pipes, etc.

Seamless black steel pipes

ERW black steel pipes

LSAW black steel pipes

black spiral welded steel pipe

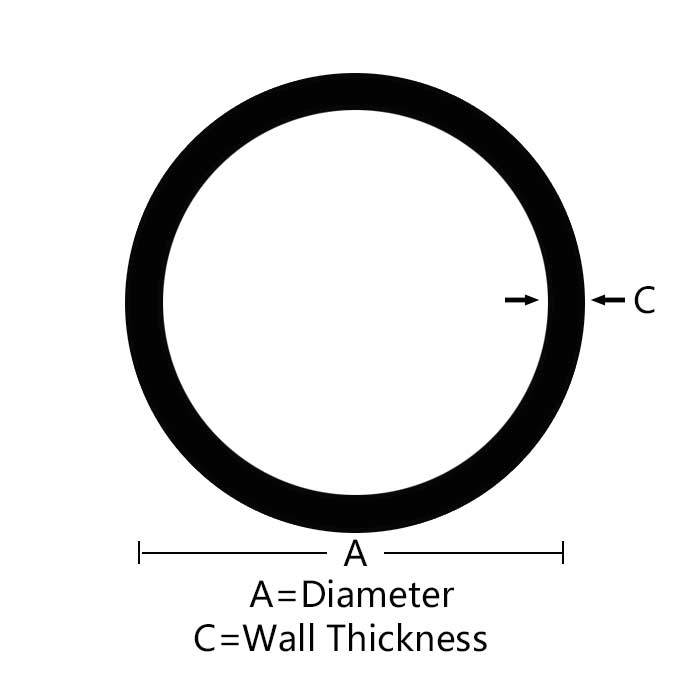

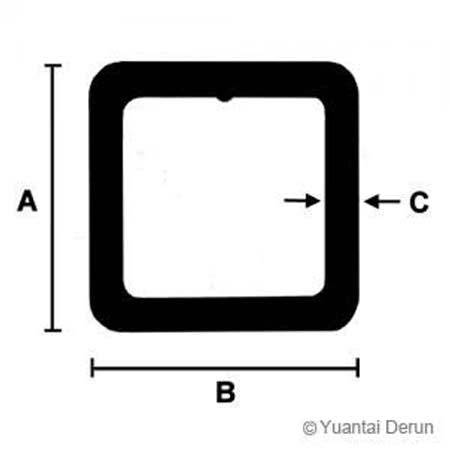

If classified by the shape of steel pipes, black steel pipes can be divided into circular black steel pipes, black square pipes, black rectangular pipes, black irregular pipes, and so on.

circular black steel pipes

A=diameter C=wall thickness

black square pipes

A=outer diameter

C=wall thickness

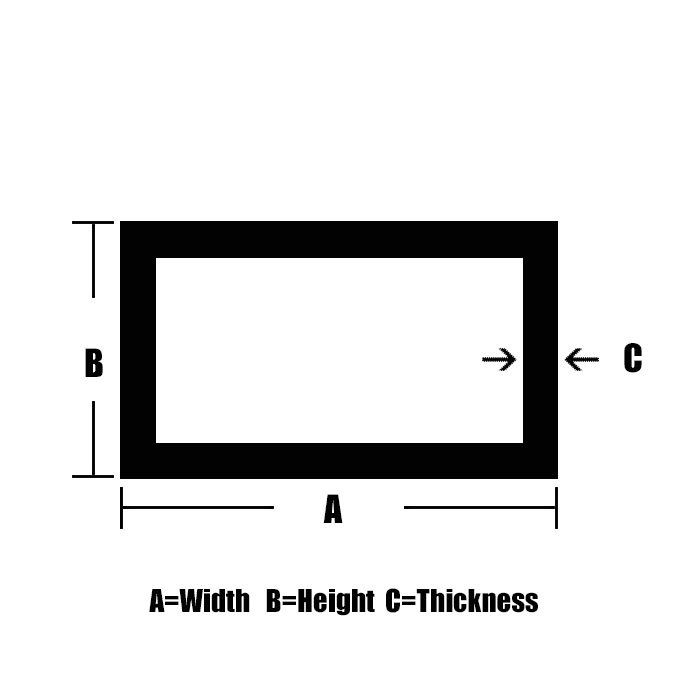

black rectangular tubes

A=width B=height

C=wall thickness

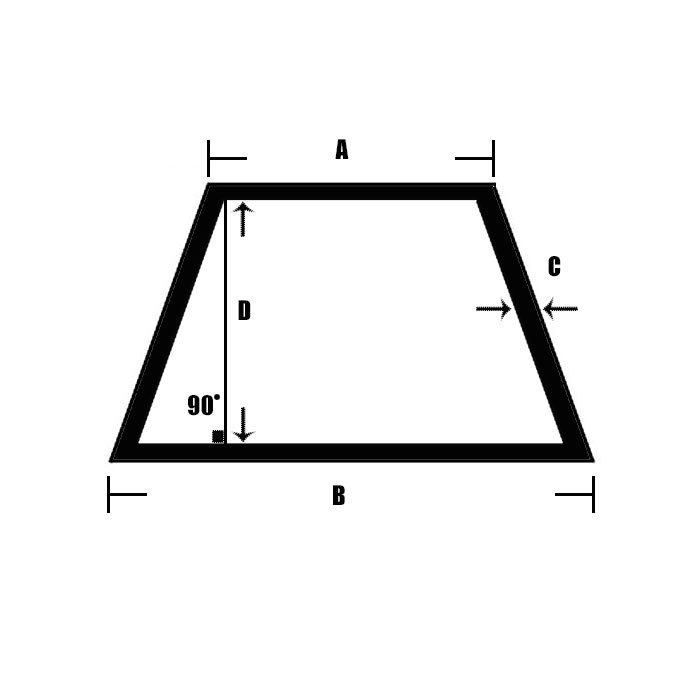

shaped tubes

black irregular pipes

10.Black Steel Pipe Manufacturing Process

The manufacturing process of black steel pipes refers to the manufacturing process of seamless steel pipes and welded steel pipes. Let me show you the manufacturing processes of various black steel pipes separately.

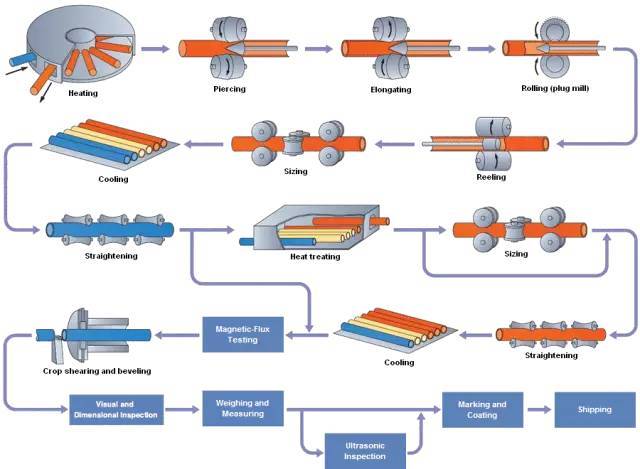

10.1 Hot rolled seamless steel pipe production process flow

The production process of hot-rolled seamless steel pipes mainly includes the following eight steps:

Step 1:Heating:

The steel billet is heated through a high-temperature furnace to achieve appropriate plasticity and toughness, providing a foundation for subsequent deformation and processing.

Step 2: Rough rolling:

The heated steel billet is preliminarily rolled through a rough rolling machine to form a certain shape and size of the tube billet.

Step 3: Precision rolling:

The rough rolled pipe blank is precisely rolled through a precision rolling machine to achieve the required pipe diameter and wall thickness.

Step 4, Cooling:

Quickly cool the precision rolled steel pipe through a cooling device to lower its temperature and increase its hardness.

Step 5, non-destructive testing:

Conduct non-destructive testing on the cooled steel pipes, such as ultrasonic testing, radiographic testing, etc., to ensure that their quality meets the requirements.

Step 6, Straightening:

Straighten the steel pipe to eliminate defects such as bending and deformation.

Step 7, Cutting and Inspection:

Cut and inspect the steel pipe according to the requirements to ensure that its length, wall thickness, and appearance meet the standards.

Step 8, Packaging:

Package the steel pipes that have passed the inspection to protect their surface and prevent rusting.

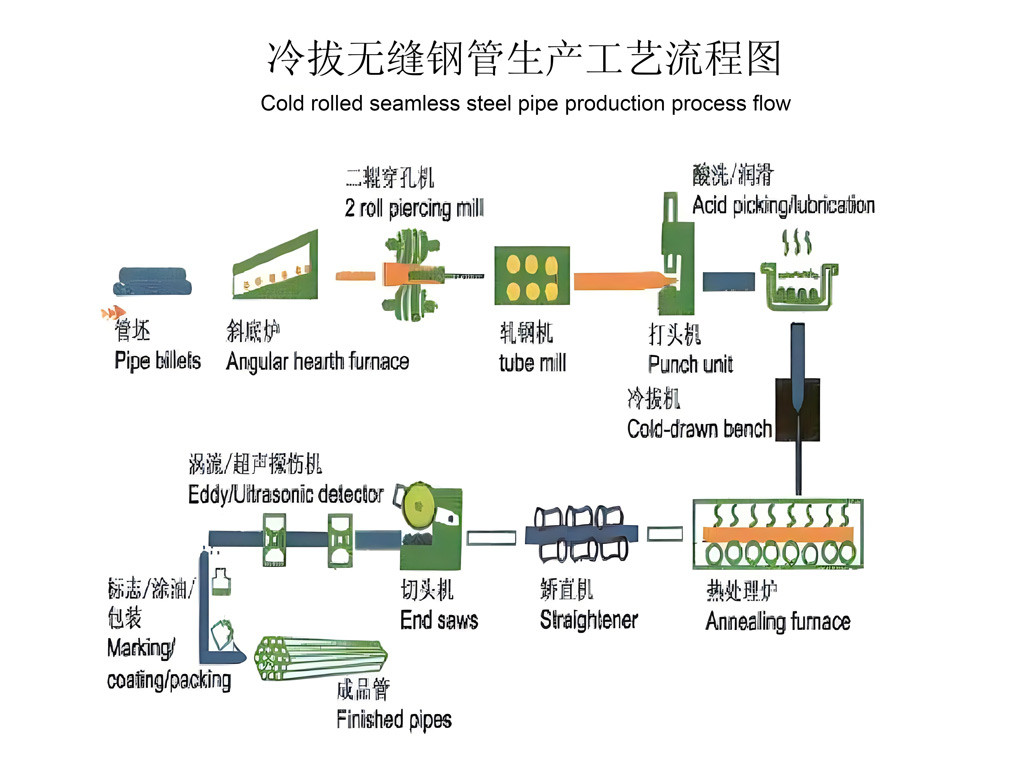

10.2 Cold rolled seamless steel pipe production process flow

Differences between hot-rolled seamless pipes and cold drawn seamless pipes

1.Different Definitions

Hot rolling is relative to cold rolling. Cold rolling is carried out below the recrystallization temperature, while hot rolling is carried out above the recrystallization temperature.

2.Different classifications

Hot rolled steel pipes are divided into general steel pipes, low-pressure and medium pressure boiler steel pipes, high-pressure boiler steel pipes, alloy steel pipes, stainless steel pipes, petroleum cracking pipes, geological steel pipes, and other steel pipes.

Cold rolled (formed) seamless steel pipes, in addition to general steel pipes, low and medium pressure boiler steel pipes, high-pressure boiler steel pipes, alloy steel pipes, stainless steel pipes, petroleum cracking pipes, and other steel pipes, also include carbon thin-walled steel pipes, alloy thin-walled steel pipes, stainless steel thin-walled steel pipes, and special-shaped steel pipes.

3.Different accuracies

Hot rolled seamless pipes generally have an outer diameter greater than 32mm and a wall thickness of 2.5-75mm. Cold rolled seamless steel pipes can have an outer diameter of up to 6mm and a wall thickness of up to 0.25mm, while thin-walled pipes can have an outer diameter of up to 5mm and a wall thickness less than 0.25mm. Cold rolling has higher dimensional accuracy than hot rolling. This is also one of the reasons why cold drawn steel pipes are more expensive than hot-rolled steel pipes.

4.Different hardness

The free torsion stiffness of hot-rolled steel pipes is higher than that of cold-rolled steel pipes, so the torsional resistance of hot-rolled steel pipes is better than that of cold-rolled steel pipes.

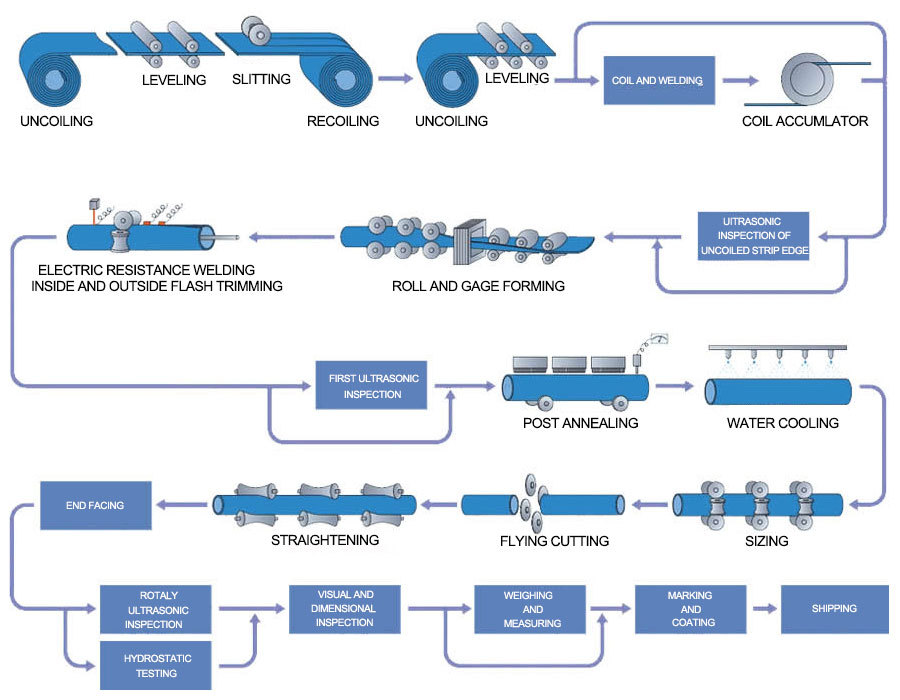

10.3 ERW black steel pipe production process flow

1. Uncoiler: Plate width 400-1250mm, detachable inner diameter φ 610-760mm, outer diameter φ 1200-1800 (max2000mm) mm, material ≤ X70 (standard APISpec5L)

2. Pinch leveling machine: steel strip width 400-1250mm; Steel strip thickness 4-14mm;

3. Cutting and welding machine: Steel strip width 400-1250mm, steel strip thickness 4-14mm, material X70;

4. Horizontal spiral loop: feed circle diameter φ 12000mm, discharge circle diameter φ 4600mm, spiral angle of steel strip on discharge circle 5.363 °, inlet speed 40-180m/min, outlet speed 8-25m/min;

5. Precision leveling machine: steel strip width 430-1250mm, steel strip thickness 4-14mm, leveling roller diameter φ 180mm, roll body length 1350mm.

6. Disc cutting machine: disc diameter φ 480mm, shear method tension shear;

7. Forming machine: Outer diameter of steel pipe φ 127- φ 381 (5 "-15") steel pipe wall thickness 4-14mm, steel pipe length 6-14m, high-frequency straight seam connection welding roller cold bending (W forming)

8. Welding unit: Steel pipe diameter φ 127- φ 381mm, wall thickness 4-14mm

9. Sizing unit: Steel pipe diameter φ 127- φ 381mm, wall thickness 4-14mm;

10. Rolling cutting: cutting range φ 127- φ 381, wall thickness 4-14mm, cutting speed 30m/min.

11. Flat head chamfering machine: machining range φ 127- φ 381, wall thickness 4-14mm, processing capacity of 2 pieces/min

12. Hydrostatic testing machine: Applicable range φ 127- φ 381, maximum test pressure of 25Mpa, processing speed of 1.5 roots/min

13. Online ultrasonic testing machine: Applicable range, pipe diameter φ 127- φ 381, vertical linearity better than 3%, horizontal linearity better than 1%, dynamic range ≥ 35dB, defect detection rate ≥ 95%, sensitivity margin better than 35dB

14. Offline ultrasonic testing machine: Applicable range, pipe diameter φ 127- φ 381, vertical linearity better than 3%, horizontal linearity better than 1%, dynamic range ≥ 35dB, defect detection rate ≥ 95%, sensitivity margin better than 35dB

15. Intermediate frequency thermal processor: 2 units with a power of 600KW, heating temperature of 500 ℃ -1200 ℃, frequency of 1KHZ-2KHZ, speed of 6-25m/min, heating width ≥ 20mm, material X70, sleeve J55.

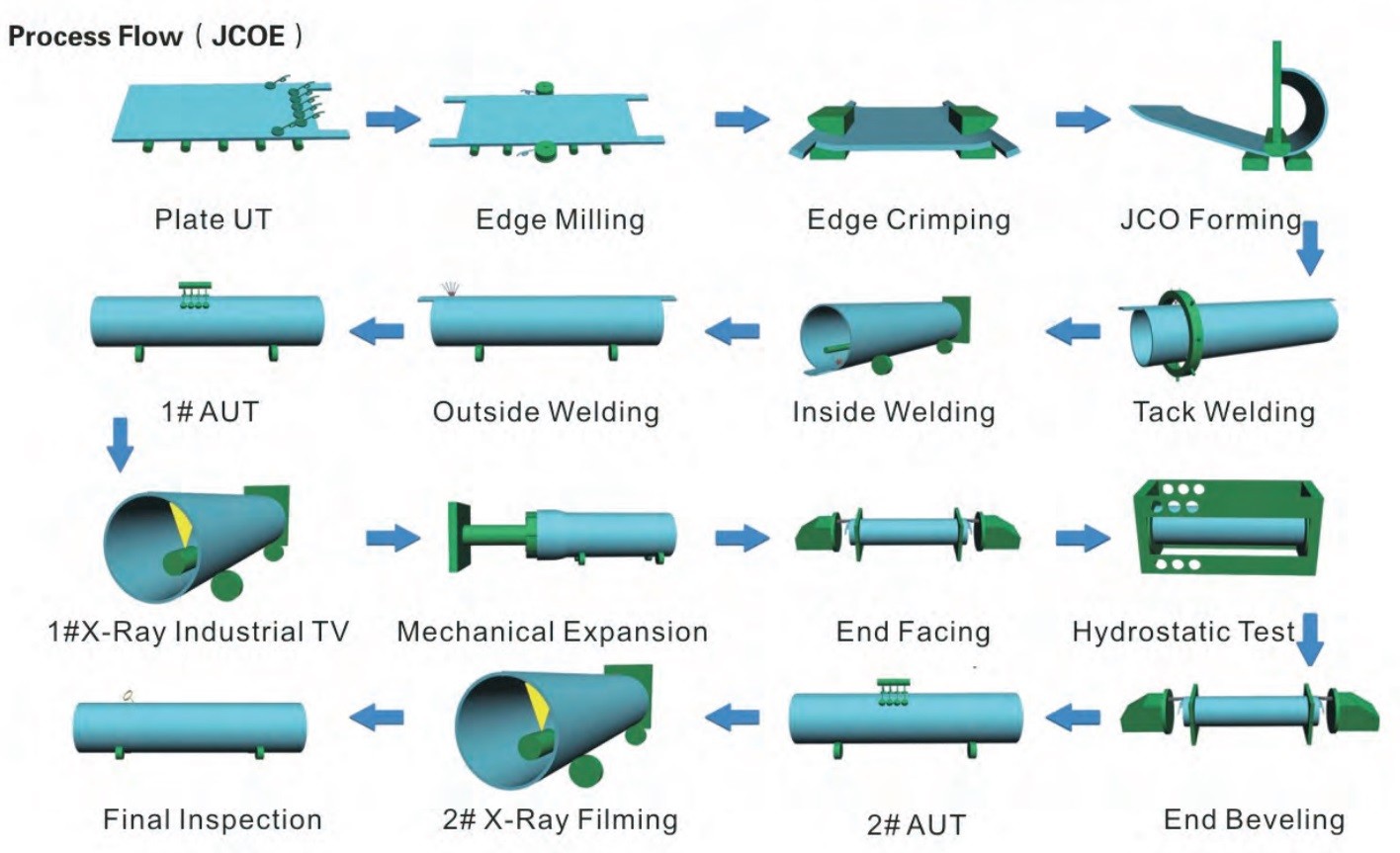

10.4 LSAW black steel pipe production process flow

Plate UT-> Edge Milling->Edge Crimping->JCO Forming->Tack Welding->Inside Welding->Outside Welding->1# AUT->1#X-Ray Industrial TV->Mechanical Expansion->End Facing->Hydrostatic Test->End Bebeling->2# X-Ray Filming->Final Inspection

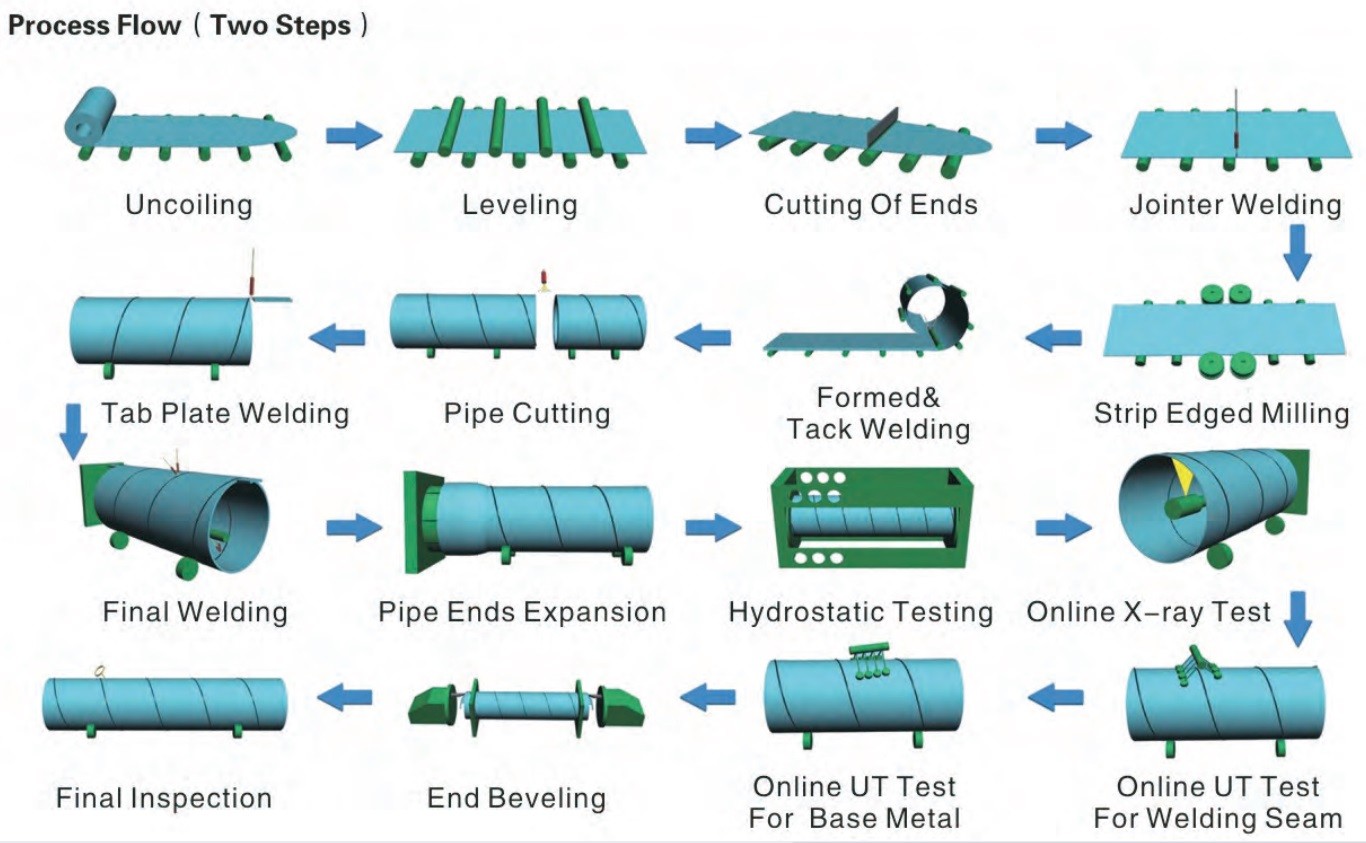

10.5 SSAW black steel pipe production process flow

Uncoiling-> Leveling ->Cutting Of Ends->Jointer Welding->Strip Edged Milling->Formed&Tack Welding->Pipe Cutting->Tab Plate Welding->Final Welding->Pipe Ends Expansion->Hydrostatic Testing->Online X-Ray Test->Online UT Test For Welding Seam->Online UT Test For Base Metal->End Beveling->Final Inspection

11. Black Steel Pipe Size

11.1 ERW pipe sizes

• ERW high-frequency straight seam welded steel pipe outer diameter: φ 10.3- φ 711mm (irregular sizes can be customized)

• Steel pipe wall thickness: 0.5-26mm.

• Steel pipe length: 6-18m.

• Steel pipe material: Q235B/Q345B/L245/L290/L360/L415/L485/20 #/API 5L B/X42/X46/X52/X56/X60/X65/X70/X80, etc.

• ERW steel pipe execution standards: GB3091-2001 GB9711.1 GB9711.2 API5L API 5CT, etc.

11.2 LSAW Steel Pipe Size

• Usage: Oil and gas transportation, building piling

• Standards: API 5L, API 5CT, ASTM 53, EN10217, DIN 2458 IS 3589, GB/T3091, GB/T9711,EN10219/EN10210,ETC.

• Company certificates: API 5L PSL1/PSL2, CE PED, ISO9001, ISO14001, ISO18001, etc

• Outer diameter: 219mm – 1820mm (8 "-72")

• Wall thickness: 5.0-500mm

• Length: 6-12.2m

• Steel grade standard: American standard API 5L: GR B, X42, X46, X56, X60, X65, X70

• ASTM A53: GR A, GR B, GR C

• European standard EN: S275, S275JR, S355JRH, S355J2H

• GB: Q195, Q215, Q235, Q345, L175, L210, L245, L320, L360-L555

• Surface requirements: Brushing black paint or 3PE anti-corrosion

• All new materials; The surface of the coating shall be free from cracking, pitting, holiday coating, rust resistance, etc.

11.3 SSAW Steel Pipe Size

• Steel pipe outer diameter: 219-3620mm,

• Wall thickness 5-26mm,

• Length 6-20 meters

• Pipe ends: butt welded flat end, beveled end, socket end, spherical end

• Materials: Q235A, Q235B, 10 #, 20 #, Q345 (16Mn)

API 5L PSL1: L245 (B), L290 (X42), L320 (X46), L360 (X52), L390 (X56), L415 (X60), L450 (X65), L485 (X70)

API 5L PSL2: L290NB/MB (X42N/M), L360NB/MB (X52N/M), L390NB/MB (X56N/M), L415NB/MB (X60N/M), L450MB (X65), L485MB (X70)

• Standards: ASTM A252, ASTM A139, AWWA C200, API 5L PSL1 PSL2, GB/T9711.1-1997, SY/T5037-2000, SY/T5040-2000, GB/T8163

• Hot dip galvanizing of steel pipes: Standard: GB/T13912-2002

• External anti-corrosion of steel pipes: epoxy resin, single-layer and double-layer epoxy powder (FBE), three-layer polyethylene (3PE), double-layer polypropylene (2PP), three-layer polypropylene (3PP), epoxy resin (epoxy), coal tar pitch, direct buried insulation and other pipeline internal and external anti-corrosion engineering shall comply with DIN30670, DIN30671, SY/T0413-2002, SY/T0414-2002 standards Akzo Nobel Paint (International Paint 954)

• Internal anti-corrosion of steel pipes: epoxy resin, lined with plastic FBE, PE, EP, epoxy coal tar, cement mortar, 3PP polypropylene, polyurethane anti-corrosion. Akzo Nobel Paint (International Paint 954) Haihong Elderly Brand Epoxy Resin 4588015570 Epoxy coal enamel, chlorinated rubber alkyd paint for corrosion prevention.

11.4 Hot Rolled Seamless Steel Pipe Size

The following is the size specification table for hot-rolled seamless steel pipes:

• φ:10-820mm

• WT:0.5-45mm

11.5 Cold Rolled Seamless Steel Pipe Size

The following is the size specification table for cold rolled seamless steel pipes:

• φ:6-820mm

• WT:1-45mm

11.6 High Pressure Seamless Steel Pipe Size

The following is the size specification table for high pressure seamless steel pipes:

• φ:16-1420mm

• WT:2-100mm

11.7 Seamless Steel Tubes For Structural Purposes Size

The following is the size specification table for structural seamless steel pipes:

• φ:16-1420mm

• WT:1-60mm

12. Black Steel Pipe Fitting

Pipe fitting is a collective term for the components in a pipeline system that serve as connections, controls, diverts, seals, supports, and more. Black steel pipe fittings refer to fittings made of steel.

Steel fittings are all pressure fittings. According to different processing techniques, it can be divided into four categories, namely butt welded fittings (divided into welded and non welded types), socket welded and threaded fittings, and flange fittings.

Summary

In summary, black steel pipes are a type of steel hollow section without any coating. It is widely used in fluid transportation and structural support applications. Having advantages such as high strength, good toughness, stable performance, and low cost, it is a rare metal building material product for you. That's all for the discussion of black steel pipes in this article. If you have any questions, please send an inquiry on the website.

FAQ:

1.can you use black steel pipe for water?

NO,it is best not to use it directly, unless your black steel pipe has undergone surface treatment such as hot-dip galvanizing.

2.Does Black Steel Pipe Rust?

Yes,black steel pipes are prone to rust and oxidation if exposed to air.