ERW vs Seamless Steel Pipe: What You Need to Know

- Share

- Issue Time

- Dec 17,2025

Summary

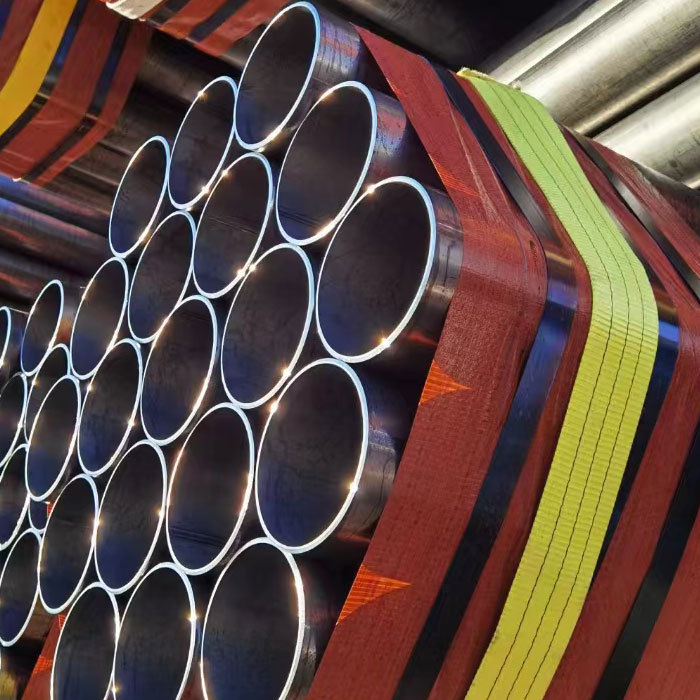

Steel pipes play a vital role in modern industry by supporting structures, transporting fluids, and protecting critical systems. People often compare ERW and seamless steel pipes because they look similar but are made differently. Their distinct production processes affect mechanical properties, pressure capacity, and cost, so understanding these differences helps buyers select the right pipe efficiently.

ERW vs Seamless Steel Pipe: What You Need to Know

Steel pipes are essential in modern industry. They support structures, transport fluids, and protect critical systems. People often compare ERW pipes and seamless steel pipes because they look similar but serve different purposes.

Even though both follow international standards, their production processes differ. These differences affect mechanical properties, pressure capacity, and cost efficiency. Understanding them helps buyers choose the right pipe without overspending.

What Is ERW Steel Pipe?

ERW steel pipes are made from high temperature steel sheets. Manufacturers gradually roll flat steel into a round shape and use an electric current to heat the edges. Then they press the heated edges together to create a continuous seam.They do not add any extra filler metal, which makes ERW pipes different from traditional welded pipes.

After welding, the steel pipe needs sizing, straightening.And sometimes receives heat treatment to reduce internal stress and improve seam quality. Manufacturers usually choose ERW pipes for large projects because it reduces waste and improves equipment efficiency.

What Is Seamless Steel Pipe?

Seamless pipes contain no weld seam. Workers start with a solid steel billet, heat it, and pierce it to make a hollow section. Then they roll or stretch the tube until it reaches the right diameter and wall thickness.

The continuous metal from inner to outer surface distributes stress evenly. This makes seamless steel ideal for piping systems that must handle high pressure or high temperature. Heat treatment can further improve mechanical properties.

Manufacturing Differences and Their Effects

The key difference is the weld seam:

ERW pipes have one longitudinal seam. Automated production lines inspect the seam using ultrasonic or eddy current testing.

Seamless pipes have no seam, but billet quality and piercing accuracy are critical to avoid internal defects.

Mechanical Performance

Seamless pipes usually handle higher pressure because their structure is uniform. Manufacturers design ERW pipes for low- to medium-pressure systems, and the pipes consistently meet the required mechanical properties.

Impact resistance depends on steel grade and heat treatment, not just the manufacturing method. Both types can meet strict requirements when properly specified.

Dimensional Accuracy and Surface

ERW pipes often have tighter tolerances thanks to cold forming. Wall thickness varies less, and surfaces are smoother. Seamless pipes are hot-formed, which can create wider tolerances and may need extra surface processing to remove scale.

Cost and Efficiency

ERW pipes are usually more cost effective, with faster production and minimized waste. Seamless pipe production is more complex, energy-intensive, and produces more scrap. This makes ERW ideal for construction and other projects where reducing costs is important.

Common Applications

ERW pipes: Construction (scaffolding, handrails), water conveyance, cross linked polyethylene systems.

Seamless steel pipes: High-pressure oil and gas, boilers, heat exchangers, and heat resistant piping systems.

Always follow standards: engineering compliance matters more than personal preference. Using the wrong pipe increases practical risk.

How to Choose

Check operating pressure, temperature, and safety margins first. Regulatory requirements and project budget come next.Overdesigning wastes money, but under-specifying risks system failure.

If standards allow it, ERW pipes offer a practical, high quality, and cost effective solution. When uniform structure is essential, seamless steel is the better choice.

Conclusion

ERW and seamless steel pipes have different roles. Neither is universally superior; each works best within its intended range. Understanding steel production, heat treatment, and mechanical properties helps make smarter choices, minimize waste, and protect long-term project value.