How is GI pipe manufactured?

- Share

- publisher

- Tianjin Yuantai Derun Steel Pipe Manufacturing Group Ltd.

- Issue Time

- May 27,2024

Summary

There are 2 manufacturing processes for galvanized steel pipes, one is the pre galvanized steel pipe manufacturing process, and the other is the hot-dip galvanized steel pipe manufacturing process.

The application of galvanized pipes(gi pipe) is very extensive, widely used in agricultural greenhouses, buildings, steel structures, factory building, mechanical manufacturing, fluid transportation and other industries. Understanding the manufacturing process of galvanized pipes is very necessary for us to better use galvanized pipes. The article brought by the editor today is about the manufacturing process of galvanized pipes. After reading it, you will definitely have a comprehensive understanding of the manufacturing process of galvanized pipes.

Definition Of Galvanized Pipes(gi pipe)

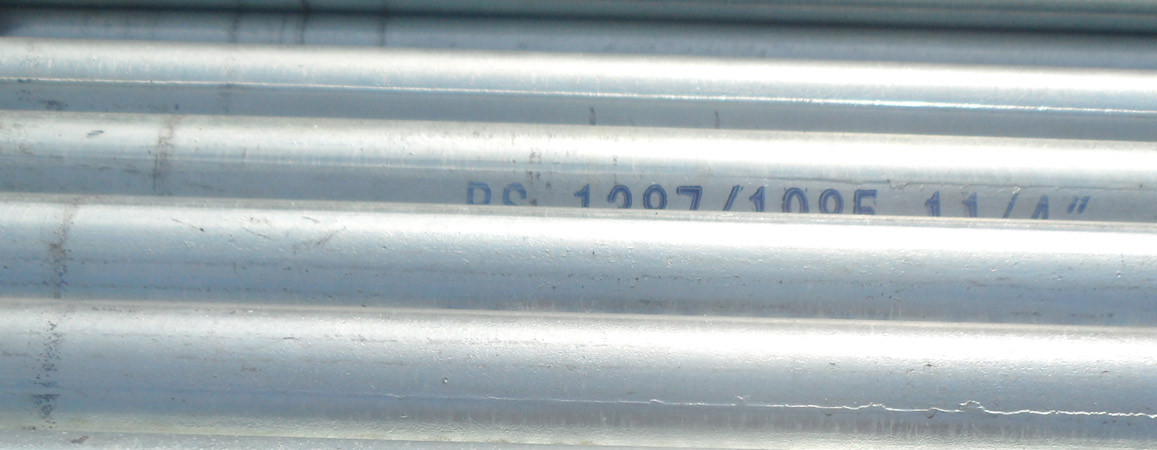

Galvanized pipe is a welded steel pipe or seamless steel pipe with a hot-dip or electroplated coating on its surface.The galvanizing process has greatly improved the service life and corrosion resistance of steel pipes. Make the application of steel pipes more widespread.

Type Of Galvanized Pipe Manufacturing Process

The manufacturing process of galvanized pipes on the market can be divided into two types: one is the manufacturing process of pre galvanized pipe(galvanized strip pipes), and the other is the manufacturing process of hot-dip galvanized pipes. The key difference between the two is the amount of zinc added. The zinc content on galvanized strip pipes is relatively low, the pipe wall is thin, the diameter is small, and the price is relatively cheaper. The service life is generally shorter than that of hot-dip galvanized pipes. The hot-dip galvanized pipe has the characteristics of high zinc content, thick pipe wall, large diameter, high price, and long service life.

What Are The Raw Materials For GI Pipes?

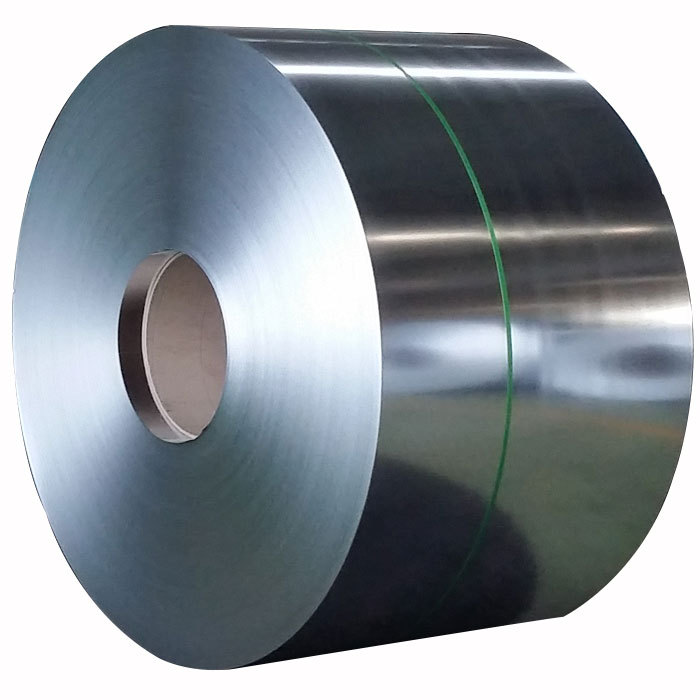

Raw Material :Galvanized Steel Coils(GI coil)

Galvanized steel coil(gi coil) is the raw material for manufacturing pre galvanized steel pipes(galvanized strip pipes).

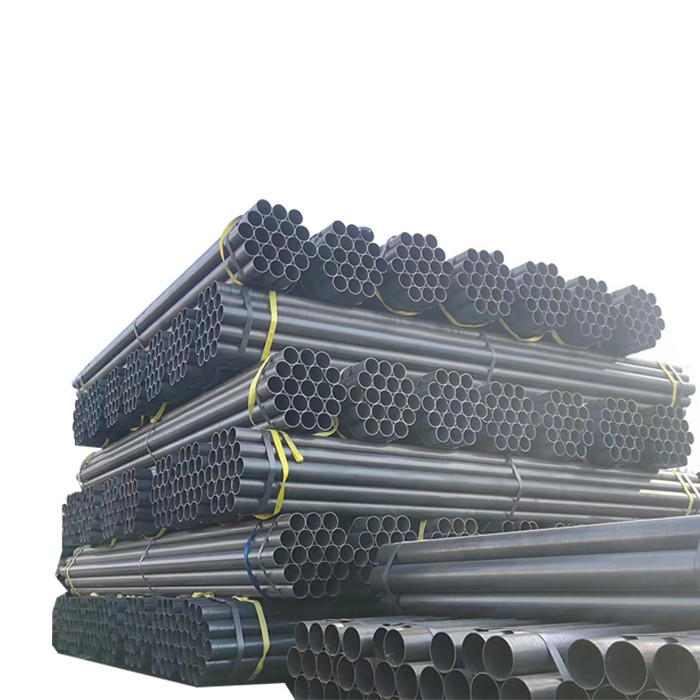

Raw Material:Black Steel Pipes

Black Steel Pipe(round steel pipe,square pipe,rectangular steel pipe) is the raw material for manufacturing hot dip galvanized steel pipes.

What Is The Process Of Galvanized Pipe?

Galvanized pipes are divided into galvanized strip pipes and hot-dip galvanized steel pipes. Let's take a look at the manufacturing processes of these two types of galvanized pipes separately.

Pre Galvanized Steel Pipe Manufacturing Process

Galvanized strip steel coil ->Uncoiling ->Cutting edge welding ->Straightening ->Cold forming ->High frequency welding ->Weld seam removal ->Fixed length cutting ->Testing ->Packaging and warehousing

Hot-dip Galvanized Pipe Production Process

Black pipe inspection: Inspect black carbon steel or seamless steel pipes to ensure compliance with requirements.

Hanging: Hanging steel pipes on the production line.

Degreasing: Use degreaser to remove grease and dirt from the surface of steel pipes.

Rinsing: Rinse the steel pipe to remove residual degreaser.

Acid cleaning: Use acid cleaning agent to remove oxide skin and rust on the surface of steel pipes.

Cleaning: Thoroughly clean the pickling agent and rust on the surface of the steel pipe.

Immersion coating agent: A layer of coating agent is formed on the surface of the steel pipe to enhance the adhesion of the galvanized layer.

Hot air drying: Dry the plating agent on the surface of the steel pipe.

Hot dip galvanizing: Immerse a steel pipe in molten zinc solution to form a layer of galvanized coating on the surface of the steel pipe.

Cooling: Remove the steel pipe from the zinc solution and cool it.

Passivation and rinsing: Passivation treatment is applied to the surface of steel pipes to enhance their corrosion resistance, followed by rinsing to remove residual passivation agents and impurities.

Unloading: Unloading steel pipes from the production line.

Inspection and repair: Conduct quality inspection on steel pipes and repair surfaces that do not meet the requirements.

Packaging and transportation: Pack and store qualified steel pipes, and arrange transportation.

The above is all about the manufacturing process of galvanized pipes. Whether it is the manufacturing process of pre galvanized pipes or hot-dip galvanized pipes, they can extend the service life of steel pipes, improve their corrosion resistance, and make their applications more widespread. If you have any questions about galvanized pipes, please contact our customers and we are happy to answer them for you.