How to make a seamless steel tube?

- Share

- publisher

- Tianjin Yuantai Derun Steel Pipe Manufacturing Group Ltd.

- Issue Time

- May 24,2024

Summary

Seamless steel pipes are the main category of pipelines widely used. The manufacturing process, advantages and disadvantages, and application scenarios of seamless steel pipes.

Foreword

Seamless steel tube is a widely used type of pipe, widely used in industries such as petroleum, natural gas, chemical, and mechanical manufacturing. Understanding the manufacturing process of seamless steel pipes can better grasp the unique advantages of seamless steel pipes and facilitate their better use. The editor has compiled an article on the manufacturing process of seamless steel pipes. Reading this article can give you a comprehensive understanding of seamless steel pipes.

1.What Is Seamless Steel Tube?

Seamless steel tube is a long piece of steel with a hollow cross-section and no seams. It is made from steel ingots or solid billets by piercing and then hot or cold rolling.

2.Type Of Seamless Steel Tube

Usually, seamless steel pipes are divided into three categories based on different raw materials: seamless carbon steel pipes, stainless steel seamless pipe, and alloy seamless steel pipes. Each type of seamless steel pipe has different manufacturing processes, characteristics, and applications.

3. How Is Seamless Steel Pipe Made?

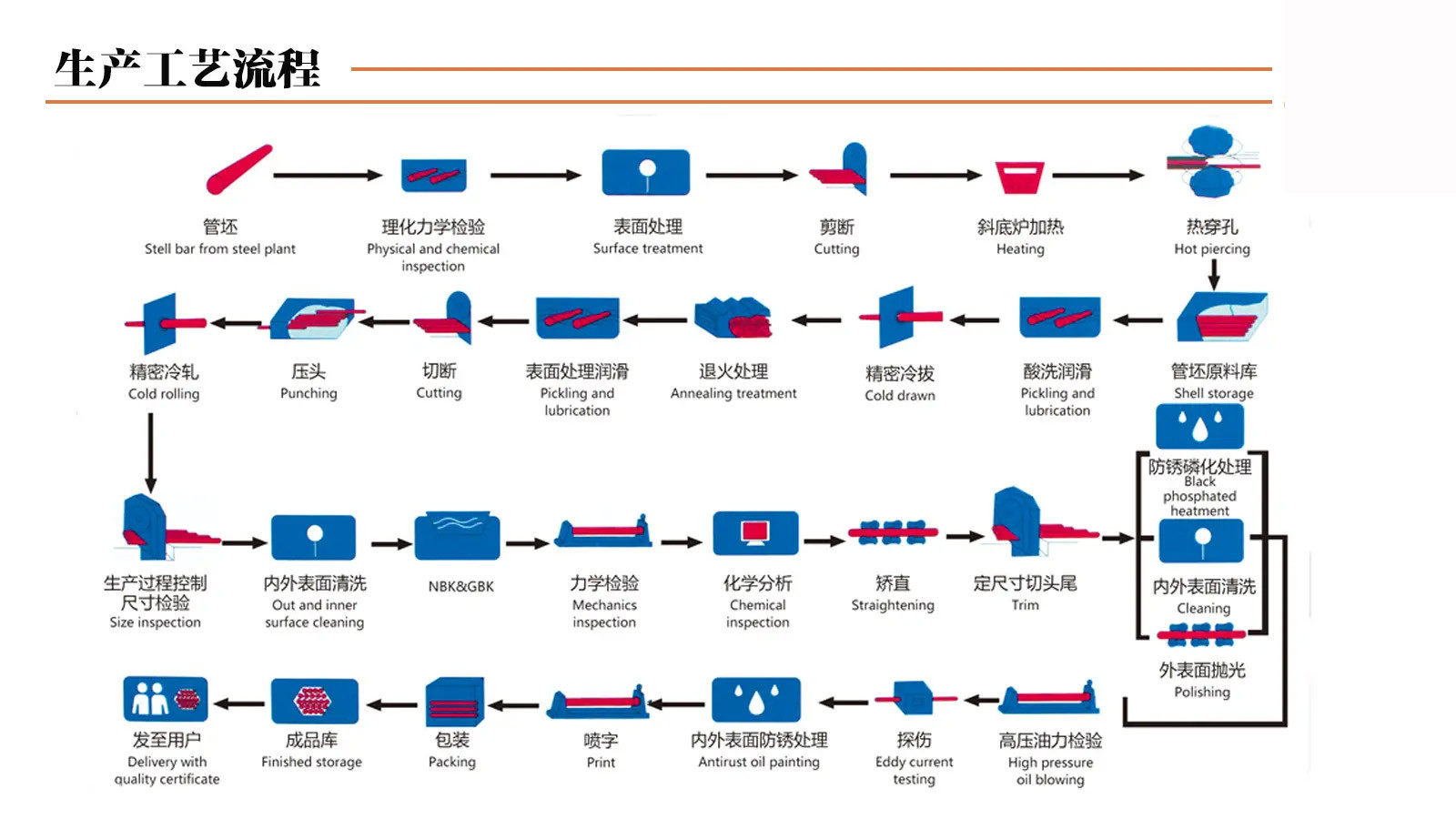

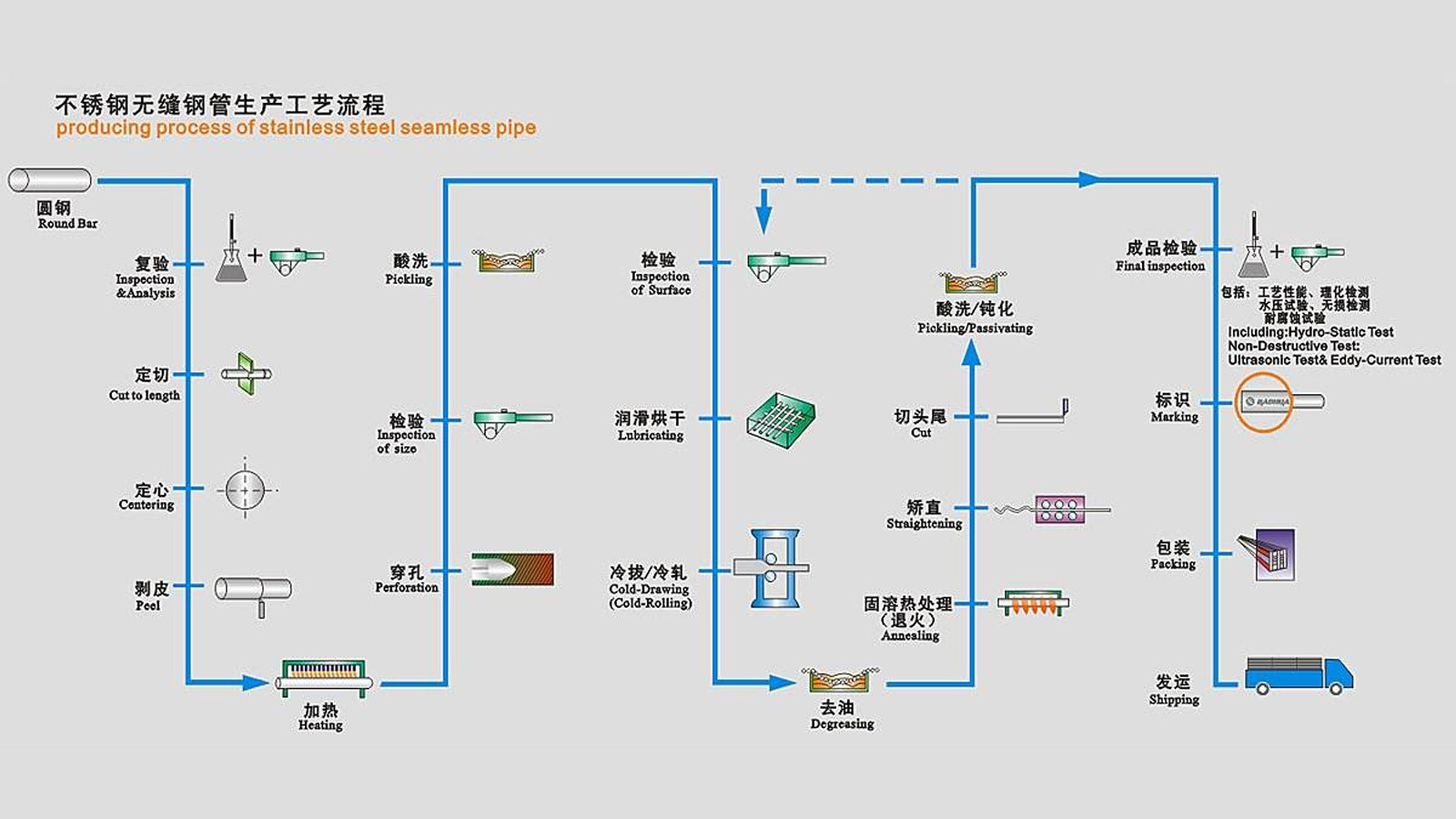

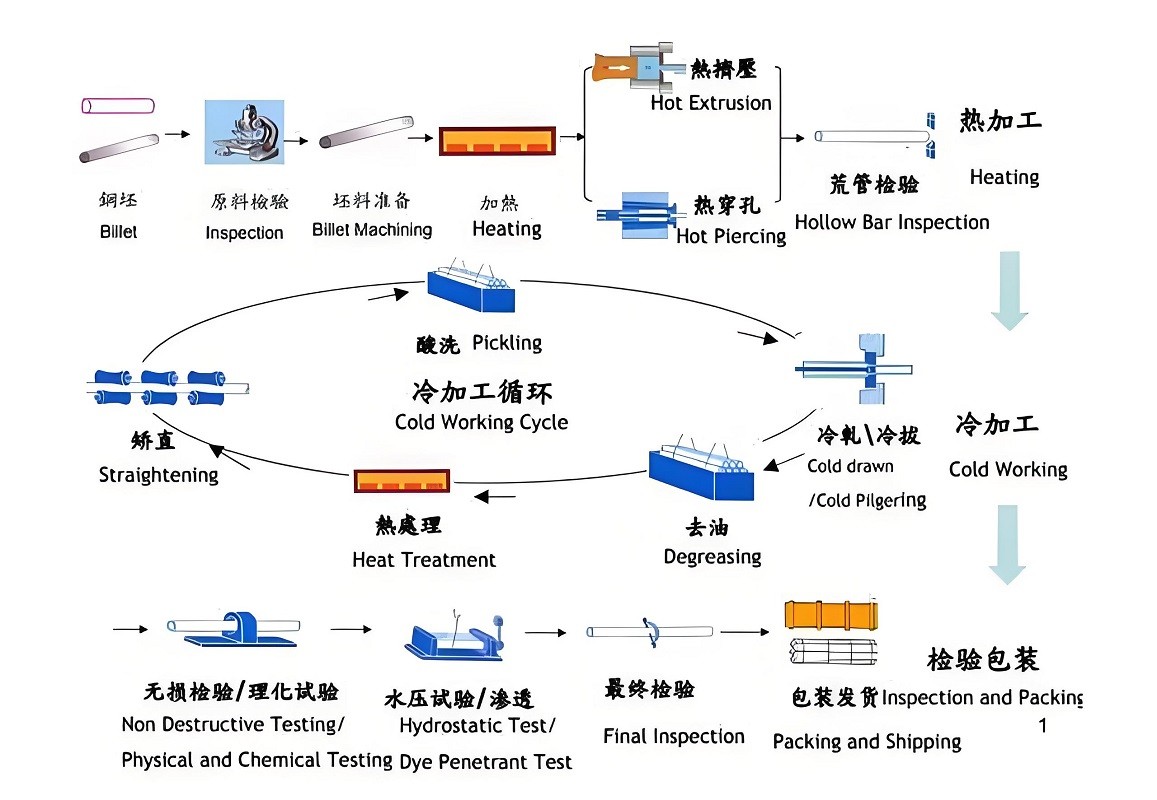

We can see two manufacturing processes for seamless steel pipes from the picture below.

Steel bar from steel plant->Physical and chemical inspection->Surface treatment->Cutting->Heating->hot piercing->Shell storage->Pickling and lubrication->Cold drawn->Annealing treatment->Pickling and lubrication->Cutting->Punching->Cold rolling->Size inspection->Out and inner surface cleaning->NBK&GBK->Mechanics inspection->Chemical inspection->Straightening->Trim->Black phosphated heatment/Cleaning/Polishing->High pressure oil blowing->Eddy current testing->Antirust oil painting->Print->Packing->Finished storage->Delivery with quality certificate.

Seamless Carbon Steel Pipe Manufacturing Process Flow

Stainless Steel Seamless Pipe Manufacturing Process Flow

Alloy Seamless Steel Pipes Manufacturing Process Flow

5. Advantages, Disadvantages, And Applications

Seamless Carbon Steel Pipes Advantage

Strength and Durability

Seamless steel tubes are strong and can withstand high pressure and heavy loads. They don't have welded seams, so they don't develop weak spots and are more durable.

Corrosion Resistance

These tubes are more resistant to corrosion than other steel tubes. This makes them suitable for harsh environments.

Uniformity

Carbon steel seamless pipe has an even distribution of stress on the inner wall, which is very uniform when conveying fluids inside, and is often used in industries such as oil and gas.

Variety of Sizes

These tubes come in different sizes and thicknesses.

Disadvantage

Seamless steel tubes are more expensive to make than welded tubes because they are more complex to make.

Seamless tubes may have a rougher surface finish than welded tubes, which might require additional work for certain applications.

Use

Oil and Gas Industry:

Steel tubes are used for drilling, transporting oil and gas, and building pipelines because they can withstand high pressure and corrosion.

Power Generation:

They are used in power plants for boilers, heat exchangers, and other high-pressure applications.

Chemical Processing:

Seamless tubes are used in the chemical industry to handle corrosive fluids and gases under high pressure.

Automotive Industry:

Used to make strong and durable parts for cars, such as drive shafts and exhaust systems.

Construction

They are used in strong, load-bearing structures like buildings and bridges.

Aerospace

Steel tubes are used in aircraft manufacturing for high-stress components because they are strong and reliable.

Stainless Steel Seamless Pipe Advantage

1. Corrosion Resistance:

Stainless steel seamless pipes are resistant to corrosion. This makes them ideal for use in harsh environments.

2. High Strength and Durability:

Seamless pipes are strong and durable. The absence of welds means they can withstand high pressure and stress.

3. Smooth Surface Finish:

Seamless pipes have a smooth surface finish, which is essential for applications requiring minimal friction and turbulence.

4. Temperature Resistance:

Stainless steel seamless pipes can withstand extreme temperatures, both high and low.

5. Hygienic Properties:

Stainless steel is easy to clean and maintain, which is crucial in industries like food processing, pharmaceuticals, and healthcare.

6. Long lifespan:

Stainless steel pipes last longer than other materials. This reduces the need for replacements and maintenance.

7. Recyclability:

Stainless steel is fully recyclable, making it an environmentally friendly choice. This also contributes to sustainability efforts in various industries.

8. Aesthetic Appeal:

Stainless steel pipes have a modern and attractive appearance, which is why they are often used in architectural applications and for visible installations.

9. Consistency in Strength:

Seamless pipes provide uniform strength throughout the entire length of the pipe, ensuring consistent performance and reliability in demanding applications.

10. Versatility:

Stainless steel seamless pipes are available in different grades and sizes, making them suitable for many applications.

Stainless Steel Seamless Pipe Disadvantage

1. High Cost:

Initial Investment: Seamless pipes are more expensive than welded pipes and other materials. The price is higher because of the cost of raw materials and the complex manufacturing process.

Maintenance: They are durable but need more maintenance. Any maintenance or repairs can be more costly due to the specialised nature of the material.

2. Complex manufacturing process:

Production is complex. Seamless pipes are more complicated and take longer to make than welded pipes. This means cutting and shaping solid blocks of metal, which requires special machines and workers.

Quality control: To make sure seamless pipes are good and consistent, you have to do lots of quality control, which can make production slower and more expensive.

3. Limited sizes and lengths: Seamless pipes have limits on size and thickness. This limits their use in large or thick pipes.

Length restrictions: Seamless pipes are usually only as long as a single piece of metal. Longer pipes may need to be joined, which can make them weaker.

4. Difficulty in machining and welding:

Harder material: Stainless steel is harder to machine and cut than other materials. This can make it more expensive and take longer to make and customise.

Specialised welding: Welding stainless steel requires special techniques to prevent defects and ensure strength. This can make installation more complex and expensive.

5. Heavier material: Stainless steel is denser and heavier than aluminium. This can be a disadvantage in applications where weight is important, like in transportation and aerospace.

6. Susceptibility to Certain Types of Corrosion:

Chloride Stress Corrosion Cracking (CSCC): Stainless steel can be susceptible to chloride stress corrosion cracking in coastal areas or chemical plants.

Pitting and Crevice Corrosion: Stainless steel can suffer from pitting and crevice corrosion in aggressive environments, which can compromise the pipes over time.

7. Thermal Expansion:

Stainless steel expands and contracts more than other materials with temperature changes. This can cause problems in applications with big temperature changes, so careful design is needed.

Stainless Steel Seamless Pipe Application

1. Petrochemical and Chemical Industries

2. Oil and Gas Industry

3. Power Generation

4. Food and Beverage Industry

5. Pharmaceutical Industry

6. Automotive and Aerospace Industries

7. Construction and Architecture

8. Water Treatment and Desalination

9. Marine Industry

10. Medical Devices

Alloy Seamless Steel Pipes Advantage

Stronger:

Seamless steel pipes are stronger than carbon steel pipes. Adding chromium, molybdenum and nickel makes them stronger and more durable.

Improved resistance to corrosion.

The addition of chromium and nickel makes these pipes more resistant to corrosion, making them suitable for harsh environments.

High temperature tolerance.

Alloy seamless steel pipes can withstand high temperatures. They are ideal for high-temperature applications like power plants and chemical industries.

Good welding and forming.

Many alloy steels are designed to be welded and formed easily, which makes manufacturing easier and allows for more complex shapes and structures.

Longevity and durability.

Alloy seamless steel pipes last longer and are more durable, so you don't need to replace them as often.

Alloy Seamless Steel Pipes Disadvantage

Higher cost.

Alloy seamless steel pipes cost more than standard carbon steel pipes because they have more alloying elements and a more complex manufacturing process.

Potential for brittleness:

These pipes can become brittle, especially at low temperatures. This needs careful selection and handling to prevent failure.

Complex manufacturing process.

Alloy seamless steel pipes are made in a more complex way, so there are fewer suppliers and longer lead times.

Specialist knowledge needed.

Using and working with alloy seamless steel pipes requires special knowledge and expertise to ensure proper handling, welding, and installation.

Alloy Seamless Steel Pipes Use

1.Power Generation 2.Petrochemical and Chemical Industries 3.Oil and Gas Industry 4.Aerospace and Automotive 5.Construction and Infrastructure 6.Marine Applications 7.Nuclear Industry 8.Heat Exchangers and Condensers

Conclusion

The production of seamless steel pipes is a relatively complex process. However, it is precisely because of the precise production process of seamless steel pipes that they have excellent physical and chemical properties, making seamless pipes play an irreplaceable role in a considerable number of industries. That's all for today's research on the production process of seamless pipes, hoping to be helpful to everyone. If you have any questions or technical questions about seamless steel pipes, please feel free to contact us at any time.