Seamless Tube Extrusion Process:Definition, How It Works, Applications, And Advantages

- Share

- publisher

- Tianjin Yuantai Derun Steel Pipe Manufacturing Group Ltd.

- Issue Time

- Jun 5,2024

Summary

Seamless Tube Extrusion Process:Definition, How It Works, Applications, And Advantages

In today's industrial manufacturing field, seamless steel tubes have won high recognition in the market due to their excellent physical properties and wide range of industry applicability. The extrusion process behind it is the core technology that guarantees the outstanding quality and performance of the pipe. In this article, we will discuss the definition of the seamless tube extrusion process, how it works, the detailed manufacturing process, the significant advantages and the wide range of applications, so that you can fully understand how this process can help the manufacturing industry to create higher quality products.

Translated with DeepL.com (free version)

Seamless Steel Pipe Extrusion Process Definition

Seamless steel pipe extrusion process is a manufacturing method to plastically deform the raw metal material by extrusion equipment, so as to obtain the seamless steel pipe with the desired cross-section shape and size.

How It Works?

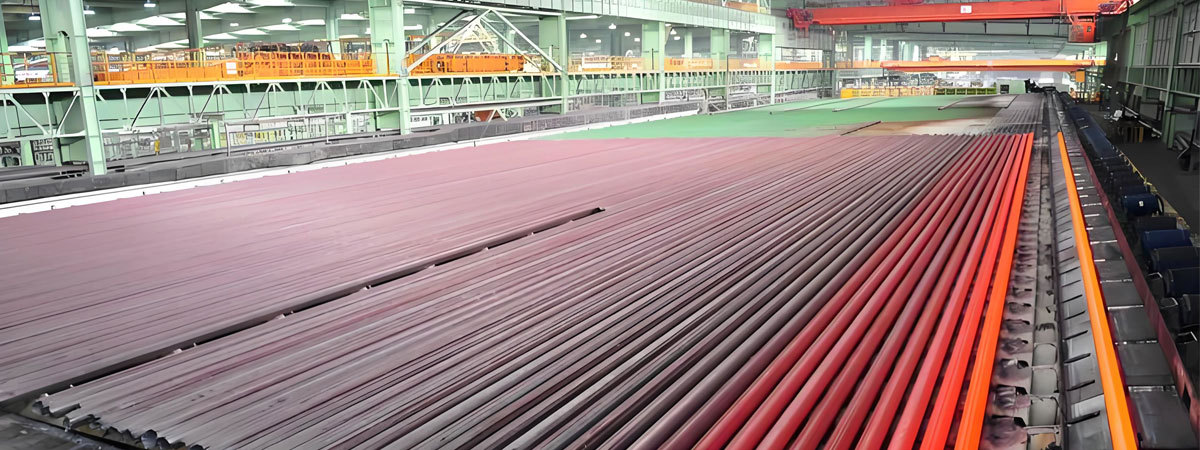

Seamless steel pipe extrusion is the use of extruder to heat the metal billet to a certain temperature, and then in the mold to apply large pressure, so that the metal billet to produce plastic deformation, so as to form a certain shape and size of the tubular metal products. During the extrusion molding process, the billet in the die cavity produces a large amount of stress and deformation, which can eliminate defects in the metal billet and make the product structure more dense.

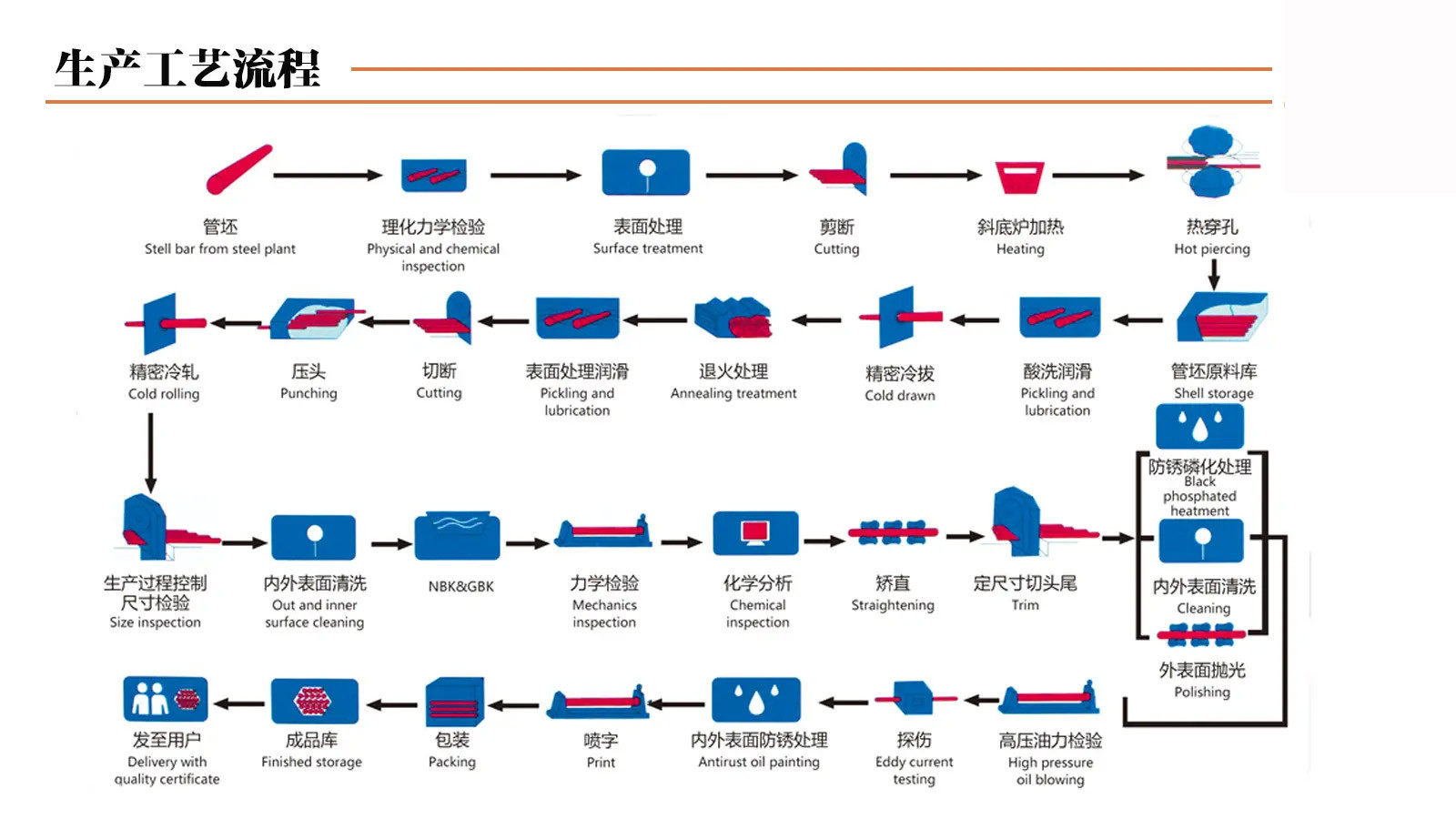

The Main Process Of Seamless Steel Pipe Extrusion Technology

1. Blank Heating

Before the extrusion molding of seamless steel pipe, the blank needs to be heated to a certain temperature. The heating temperature is generally above the recrystallization temperature of the metal, so that the metal blank can have good plasticity.

2. Pipe Extrusion

The heated blank is pushed into the extruder and extruded by the die to form a tubular metal product with a certain shape and size. The extrusion process requires high pressure to produce plastic deformation of the metal blank and continuously push the blank forward.

3. Cooling

After extrusion molding, tubes must be cooled to below room temperature. Cooling can be done with water or air.

4. Cut-To-Length

After cooling, the tubes need to be cut to length. The cuts must be accurate and not affect the tubes' properties.

5. Inspection And Warehousing

The cut steel pipe must be inspected for size and condition. Once approved, the pipe will be packed and stored until it is shipped.

Advantages Of Seamless Steel Pipe Extrusion Process

High precision: The extrusion process ensures the dimensional and shape accuracy of seamless steel pipe to meet the requirements of high-precision applications.

High strength: The plastic deformation in the extrusion process can enhance the strength and toughness of the seamless steel pipe, and improve the service life of the product.

High production efficiency: the extrusion process is characterized by continuous production, which can greatly improve production efficiency and reduce production costs.

Extruded Seamless Steel Pipe Applications

Extruded seamless steel pipe is widely used in automobile manufacturing, petrochemical industry, machinery manufacturing, high pressure boiler and other fields.

In automobile manufacturing, extruded seamless steel pipe is applied to manufacture automobile bearings, shock absorber bushings, engine cylinders and other components.

In petrochemical industry, extruded seamless steel pipe can be used to manufacture chemical pipeline, oil pipeline and other high-pressure pipeline.

In machinery manufacturing, extruded seamless steel pipe is used to manufacture machine tools, ships, compressors, hydraulic cylinders and other machinery manufacturing equipment.

In high-pressure boilers, extruded seamless steel pipe can be used in the manufacture of steam packages, heaters, supercritical boilers and other components.

In conclusion, extruded seamless steel pipe is a very important processing technology with a wide range of applications, which can provide high-quality materials and components for different industries.

How To Choose The Right Extruded Seamless Steel Pipe Products

Understand the application area of the product: according to the industry and field where the product is applied, choose the extruded seamless steel pipe products that meet the requirements. If you are not sure what kind of steel pipe is used in what environment, please feel free to contact our pipe account manager.

Focus on product quality: Choose a manufacturer with a good reputation and word of mouth to ensure reliable product quality.

Understand the production process: Understand the manufacturer's production process and equipment to ensure that the product can meet the requirements of high precision and high strength.

If you don't have a reliable seamless steel pipe supplier, you are welcome to contact the account manager of Yuantai Delun.

Factors Affecting Product Quality

The quality of seamless steel pipe extrusion molding is influenced by multiple factors, such as extrusion temperature, extrusion speed, mold shape, extrusion pressure, etc. Among them, temperature is a key factor affecting product quality. High or low temperatures can lead to unstable product quality and even problems.

Epilogue

Seamless steel pipe extrusion is key to ensuring quality. By choosing suitable raw materials, controlling the heating temperature and time, optimizing the extrusion molding parameters, and other measures, seamless steel pipe products with high precision, high strength, and good surface quality can be manufactured. When choosing seamless steel pipe extrusion process products, pay attention to the product's application, quality, and production process to ensure you buy a high-quality product that meets your needs. Contact our account manager if you have any requirements about seamless steel pipe.