Square Tubing and Round Tubing Strength: A Clear and Practical Comparison

- Share

- Issue Time

- Dec 12,2025

Summary

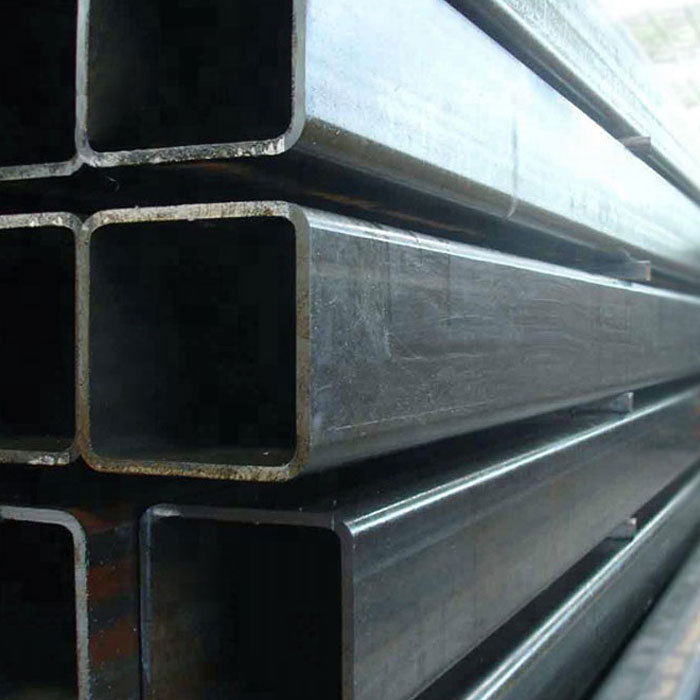

Choosing between carbon steel square tubing and round tubing often raises questions about strength. Many buyers want a direct answer, yet the comparison depends on how each shape handles force. Both forms use the same material principles, but their geometry changes how loads spread through the tube.

Square Tubing and Round Tubing Strength: A Clear and Practical Comparison

Choosing between carbon steel square tubing and round tubing often raises questions about strength. Many buyers want a direct answer, yet the comparison depends on how each shape handles force. Both forms use the same material principles, but their geometry changes how loads spread through the tube.

Round tubing shows strong performance under torsion. The circular shape allows stress to move evenly along the perimeter. No single point takes more strain than another. This quality helps the tube resist twisting forces that occur in moving structures or rotating parts. It also supports bending from multiple directions because every angle shares the load in a balanced way.

Square tubing behaves differently. The flat faces carry compression well and create stable support in one main direction. These sides give predictable bending strength along the plane of the face. The corners, however, collect more stress when the tube twists. This limits its ability to handle rotational loads but does not reduce its value in rigid frameworks or static structures.

Both shapes excel in different environments. Round tubing fits projects that experience vibration, turning, or uneven external pressure. Frames for vehicles or machinery benefit from this uniform strength. Square tubing suits applications where alignment matters more than rotation. Builders often use it for racks, gates, and architectural frames because the flat surfaces make welding and installation easier.

Load type remains the key factor. Torsion favors round tubing. Straight-line compression favors metal square tubing. Multidirectional bending also leans toward round tubing because the curved form spreads force without creating concentrated points of stress. When the design includes simple vertical support or structured layouts, square tubing performs reliably and efficiently.

Selecting the right shape requires a close look at the working conditions. Consider how the force moves through the structure. Think about whether the system faces twisting or only fixed-direction pressure. Fabrication methods also influence the choice because flat faces simplify cutting, joining, and positioning.

Both options can deliver long service life when matched to the correct application. Neither shape is universally “stronger” in every scenario. The geometry directs how the material reacts to real loads, and understanding that difference leads to better decisions. Clear knowledge of bending, torsion, and compression makes the selection process more accurate and avoids performance risks.