Types of steel pipe for your business

- Share

- publisher

- Tianjin Yuantai Derun Steel Pipe Manufacturing Group Ltd.

- Issue Time

- Dec 14,2023

Summary

Steel pipes are a common metal building material that can be seen everywhere in daily life. Do you know what types of steel pipes there are? Now let's take everyone to have a deeper understanding.

Steel pipes are a common metal building material that can be seen everywhere in daily life. Do you know what types of steel pipes there are? Now let's take everyone to have a deeper understanding.

Seamless steel pipes

Firstly, according to the production process, steel pipes can be divided into seamless steel pipes and welded steel pipes.

Seamless steel pipe refers to a general term for hollow steel pipes made by piercing round steel.

The advantages of seamless steel pipes

1.Stable performance

Due to the production process, seamless steel pipes have stable chemical composition and physical properties.

2.High strength

Seamless steel pipes have higher strength, especially in terms of tensile and compressive strength, due to the absence of welding processes.

3.Corrosion preventive

Under the same circumstances, the corrosion resistance of seamless steel pipes is better than that of welded steel pipes.

4.Uniform cross-sectional shape

Seamless steel pipes are made by continuous extrusion of alloys, and their cross-sectional shape is relatively uniform. Especially for seamless steel pipes that have undergone precision cold drawing, their inner and outer surfaces are smooth, with small errors and high dimensional stability.

Disadvantages of seamless steel pipes

1. High cost

The production process of seamless steel pipes requires the use of special production equipment and process technology, resulting in higher production costs.

2. Long production cycle

Compared with welded steel pipes, seamless steel pipes have more production processes, longer production cycles, and lower production efficiency.

3. High production difficulty

The difficulty of producing seamless steel pipes is relatively high, with strict technical requirements and relatively high equipment requirements.

The use of seamless steel pipes

The application scenarios of seamless pipes are particularly wide, such as petroleum, chemical, mechanical, natural gas, nuclear power plants, domestic pipelines, construction engineering, aerospace, power industry, and so on.

Welded steel pipes

Welded steel pipe refers to a hollow section pipe with welded seams made by forming and welding steel coils or plates.

Advantages of welded steel pipes

1. Efficient and energy-saving

The production energy consumption of welded steel pipes is relatively low, and the production cycle is relatively fast.

2. Superior performance

Welded steel pipes have superior performance compared to other materials, such as compressive strength and physical and mechanical properties. The production process of welded steel pipes has been upgraded and improved, and it is even more outstanding.

3. Larger caliber range

The diameter range of welded steel pipes is larger than that of seamless steel pipes. A welded steel pipe can have a maximum diameter of 4 meters. For seamless steel pipes, the diameter is not their advantage.

4. Good corrosion resistance

The welded steel pipe has undergone special treatment and has good corrosion resistance. In corrosive environments such as acid, alkali, and salt, welded steel pipes can be used stably for a long time, ensuring the safety and service life of the pipeline.

Disadvantages of welded steel pipes

1. High cost

Compared to other materials such as rubber pipes and plastic pipes, the cost of welded steel pipes is still relatively high.

2. High process requirements

With the development of the times, the requirements for welding technology for welded steel pipes are becoming increasingly high, and the quality requirements for welding wires or fluxes are also becoming higher.

Application of welded steel pipes

Welded steel pipes can be used in various fields such as construction, shipbuilding, aerospace, mechanical manufacturing, automotive manufacturing, etc., such as highway guardrails, industrial pipelines, power engineering, HVAC systems, etc.

Secondly, according to the material, steel pipes can be divided into carbon steel pipes, stainless steel pipes, and alloy steel pipes.

Carbon steel pipes

Carbon steel pipe is a type of pipe made from carbon steel as the raw material.

Advantages of carbon steel pipes

1.Good mechanical performance

Carbon steel pipes have excellent mechanical properties, such as high yield strength and high tensile strength.

2.Low cost

Compared to other steel pipes such as copper and stainless steel, the cost of carbon steel pipes is relatively low.

3.Easy to process

Carbon steel pipes have good processing performance and are easy to drill, mill, turn, and cut, meeting the needs of various processing techniques

Disadvantages of Carbon Steel Pipes

1. Not corrosion-resistant.

If the surface of carbon steel pipes is not processed, they are particularly prone to rusting.

2. Not resistant to high temperature and pressure.

Carbon steel pipe may deform or lose strength under some specific high temperatures and pressurized environments, so it needs to be carefully selected for use under these conditions.

3. Higher weight.

Carbon steel tubing has a high density value, which makes it heavy compared to other lightweight tubing, such as aluminum tubing and plastic tubing. This can increase the cost and difficulty of transportation.

Carbon Steel Pipe Uses

Carbon steel pipe has a wide range of uses, common uses include: construction, machinery manufacturing, petrochemical, aerospace and aviation and so on.

Stainless Steel Pipes

Stainless steel pipe is a hollow section pipe made of stainless steel.

Advantages of Stainless Steel Pipe

1. Clean and hygienic

Stainless steel pipe is now environmentally friendly and hygienic metal material, not easy to be contaminated by bacteria, no dirt, easy to clean;

2. Long life

According to test data, stainless steel tubes can last up to 70-100 years.

3. Low maintenance costs

Due to the stainless steel tube's corrosion resistance, long life and other characteristics, it will be very low maintenance costs in the later stage, almost no need to replace.

4. Corrosion resistance

Stainless steel pipe has very good corrosion resistance and is less likely to rust and scale when encountering water.

5. High temperature resistance

The maximum working temperature of thin-walled stainless steel pipe can reach over 120℃ and the minimum can reach -20℃. Other tubes will produce deformation cracking and other problems in high or low temperature environments.

6. UV resistance

There is no aging of stainless steel tubes under UV light. While other tubes, such as plastic tubes age badly under light.

7. Beautiful appearance

Stainless steel tubes have a polished surface that is especially beautiful. It is pleasing to the eye.

Disadvantages of Stainless Steel Pipes

1. High cost

Compared with ordinary carbon steel pipe, stainless steel pipe production costs, production process requirements are higher, which makes the price of stainless steel pipe is very expensive.

2. Poor thermal conductivity

Compared to ordinary steel tubing, stainless steel tubing has very weak thermal conductivity and barely conducts any heat at all.

3. Not easy to process

The processing of stainless steel tubes requires specific processing equipment and certain processing skills.

Stainless Steel Tube Uses

Stainless steel pipe, mainly widely used in petroleum, chemical, medical, food, light industry, mechanical instrumentation and other industrial pipelines, as well as mechanical structural components. In addition, due to the light weight of stainless steel pipe, it is also used to manufacture mechanical parts and engineering structures. Thirdly, due to the thermal insulation of stainless steel pipe, it is also commonly used for furniture and kitchenware, such as our 304 stainless steel insulation cup.

Alloy Steel Pipe

Alloy pipe refers to the alloy steel billet through rolling heat treatment and other processes made of steel pipe.

Alloy Steel Tube Advantages

1. High strength.

The main components of alloy steel pipe are various metal elements, their crystalline structure and bonding strength are higher than that of ordinary steel pipe, so the strength of alloy steel pipe is usually several times higher than that of ordinary steel pipe, which is able to withstand greater pressure and load.

2. High temperature resistance

The alloy composition of alloy steel pipe enables it to withstand higher temperatures and is less prone to deformation and breakage. Therefore, alloy steel pipes are often used in high-temperature environments, such as oil refineries and power plants.

3. Resistant to low temperatures

Nickel-based alloy tubes in alloy steel tubes have excellent low-temperature resistance.

4. Corrosion resistance

Compared with conventional carbon steel pipe, alloy steel pipe has better corrosion resistance, and can withstand high temperatures, high pressure and other complex environments.

Alloy Steel Tube Disadvantages

1. Easily damaged

Alloy steel pipe is more easily damaged in the process of use, compared with ordinary steel pipe. It has to be maintained and replaced frequently, which increases the cost of use and the difficulty of maintenance.

2. Expensive

The raw materials used in the manufacture of alloy tubes are more expensive and the processing is complicated, so the cost of alloy steel tubes is exorbitant.

3. Unstable corrosion resistance

Although the alloy steel pipe can be in some extreme environments, can maintain a certain performance, but time once elongated, its corrosion resistance will decline, so the corrosion resistance of alloy steel pipe is not very stable.

4. Poor weldability

Alloy steel pipes are more difficult to weld and require higher consumables such as welding rods compared to ordinary carbon steel pipes.

Alloy Steel Tube Uses

->Low and Medium Pressure Boiler Tubes

->High-pressure boiler tubes

->Nuclear power station, power plant

->Petroleum

->Natural gas

->Gas

->Low temperature piping

->Chemical piping

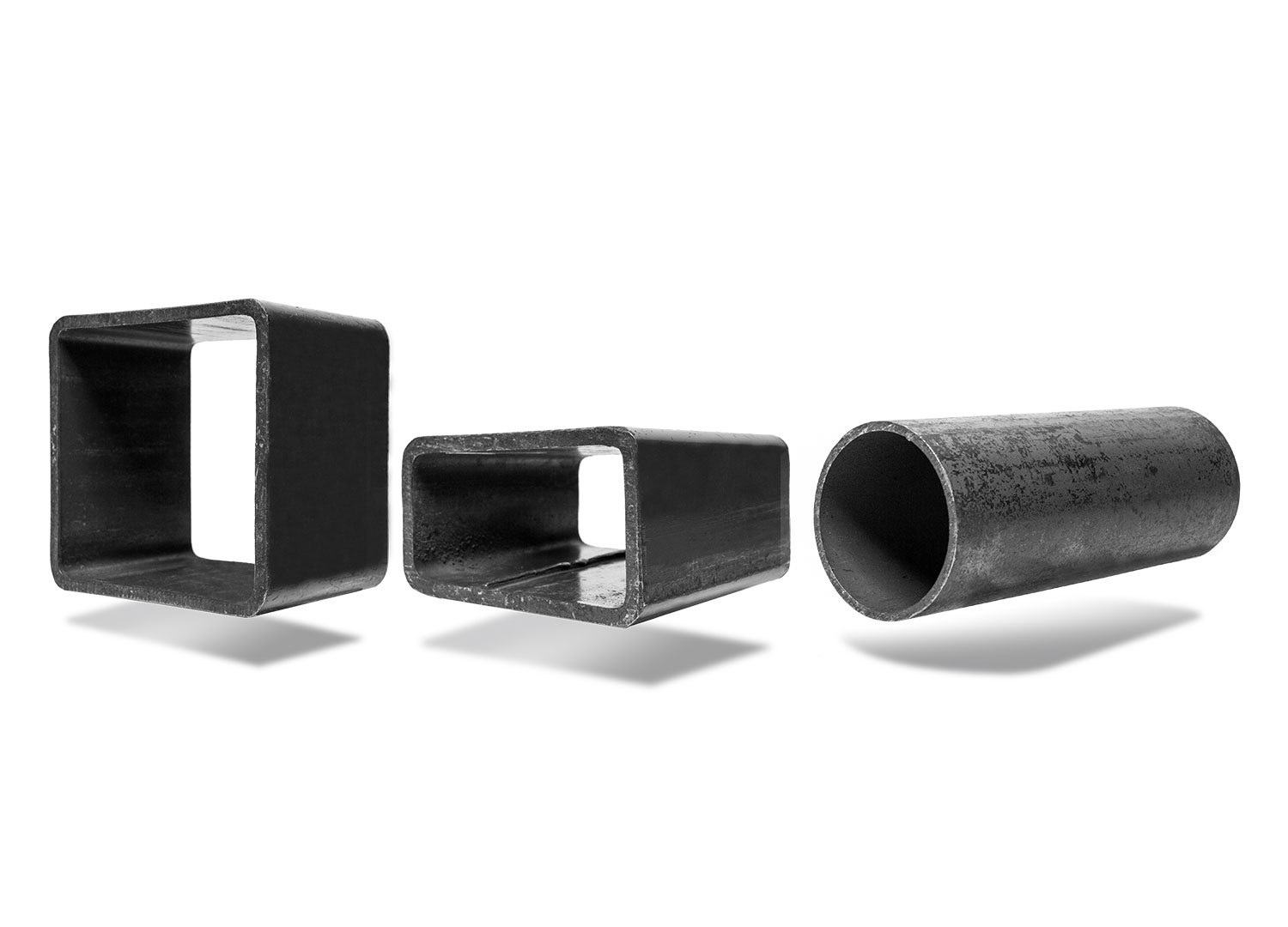

Thirdly, steel pipe can be divided into round steel pipe, square steel pipe, rectangular steel pipe and shaped steel pipe according to its shape.

Round Steel Pipe

A round steel pipe is a steel tube with a round cross-section.

Advantages of Round Steel Tubes

1. Uniform strength

Due to the circular cross-section design of the circular steel pipe, the circular pipe has a uniform load carrying capacity by evenly distributing the load in the force.

2. Easy processing

Round steel pipes have a simple cross-section and are easy to process into various shapes and sizes.

3. Good sealing

Round steel tubes can be connected by welding, threaded connections, etc., and have good sealing properties.

Disadvantages of Round Tubes

1. Difficulty in surface treatment.

The surface of round steel pipe is round and cannot be directly processed by flat grinding etc. Therefore, it is relatively difficult to process the surface of round pipe.

2. Shape limitation

Since the shape of a round tube limits its layout in a given space, it may be less suitable in some scenes where a compact layout is required.

3. Difficulty in reinforcing round tubes

It is difficult to ensure the quality of round pipe reinforcement construction, and workers are still needed to repair in the later stage, which will not only waste labor, but also delay the construction progress.

Round Steel Tube Applications

1. Conveying pipes

As a pipe shape, the most common use of round pipe is as a transportation pipe. In industrial production, round pipes are widely used to convey various liquids, gases, powders and other substances. For example, in petroleum, chemical and metallurgical industries, round pipes are used to transport crude oil, natural gas, chemicals and so on. In addition, in the water supply and drainage system, round steel pipe is also an indispensable part.

2. Structural support

Round tubes have high strength and stability, and are therefore often used as structural support materials. In the construction field, round tubes are often used to build temporary supports, scaffolding, roof trusses and so on.

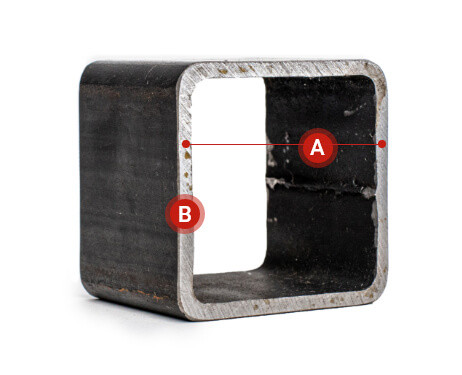

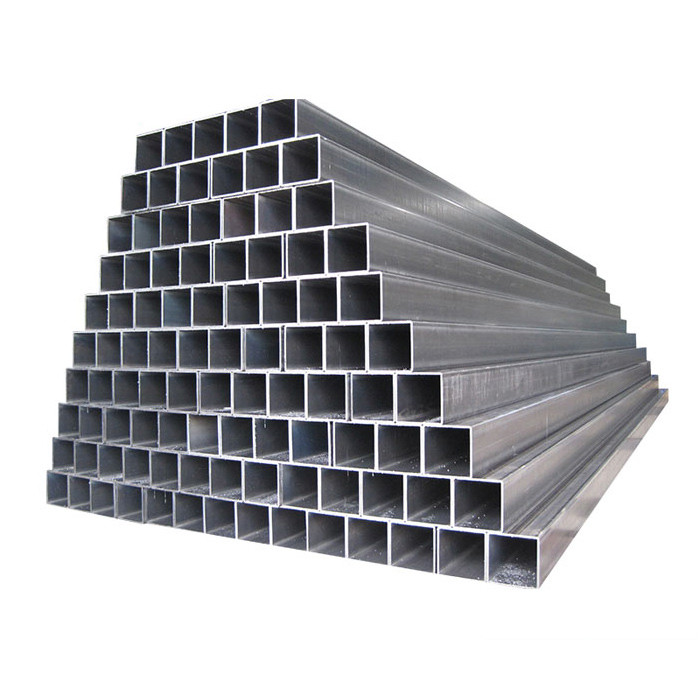

Square Steel Pipes

Square steel pipe is a type of steel pipe with a square cross-section.

Advantages of Square Steel Pipe

1. Structural stability

Square steel tubes have better structural stability. The shape and structure of square tubes determine their better structural stability. In addition, square tube also has good seismic performance. Square tube can effectively disperse and absorb the energy generated by the earthquake, improve the seismic capacity of the building, to protect people's lives and property safety.

2. High strength

Square steel pipe, strong load-bearing capacity, good pressure resistance, due to the square shape of the cross-section of the square steel pipe, compared with the round pipe, square steel pipe can provide greater strength and stiffness under the same mass, and can withstand greater loads.

3. Corrosion resistance

Square steel pipe usually adopts anti-corrosion treatment process such as galvanization or spraying, which can effectively prevent the steel pipe from rusting in the humid environment and prolong its service life.

Disadvantages of Square Steel Tubes

1. Poor bendability:

Square tubes are not as bendable as round tubes and square steel, and need to be processed using specialized bending machines. Improper processing methods can easily lead to material damage, thereby reducing service life.

2. Easily rusted:

Since the surface of the square tube is often exposed to the air, it is susceptible to oxidation and corrosion if it is not galvanized or otherwise surface-treated, reducing the service life of the material.

3. Poor sealing:

The sealing of the square tube is poor, in the same situation, compared with the round steel pipe, welding two square steel pipe, the weld is more prone to leakage of water and air leakage, requiring special construction.

Square Steel Tubes Applications

1. Construction

Square steel pipe can be used for the main structure of the building, such as stairs, handrails, ceilings and so on. Square steel pipe can also be used as the support material of the building, used to build temporary support, scaffolding and so on. Square steel pipe can also be used for building decoration, such as indoor partition, furniture making and so on. In bridge construction, square steel pipe can be used to make support structure of bridge, guardrail and so on.

2. Machine building

Square steel pipe also has a wide range of applications in the field of machinery manufacturing. It can be used to manufacture parts of machinery and equipment, such as the bed of machine tools, guide rails and so on. In automobile manufacturing, square steel tube can be used to manufacture body structure, chassis structure and so on. In shipbuilding, square steel tube can be used to manufacture hull structure, cabin structure and so on.

3. New energy industry

The main applications of square steel pipes in the field of new energy include:

1. Nuclear power plant construction:

During the construction process of nuclear power plants, square steel pipes are widely used as important structural materials for supporting and constructing key parts such as reactor buildings, cooling towers, and auxiliary buildings.

2. Aerospace field:

Square steel pipes can be used for refrigeration systems and some structural components of aircraft.

3. Application of new energy equipment:

For example, in the fields of CCUS (carbon capture, utilization, and storage), hydrogen energy, and compressed air energy storage, the demand for square steel pipes comes from transportation pipelines, centralized procurement pipelines, etc.

4. Photovoltaic field:

Square steel pipes can be used in photovoltaic brackets to convert light energy into electrical energy in conjunction with solar panels.

Rectangular Steel Pipe

Rectangular steel pipe is a type of steel pipe with a rectangular hollow section.

Advantages of Rectangular Steel Pipes

1. Better structural stability

First of all, one of the advantages of rectangular pipe is its better structural stability. Since rectangular tubes have a rectangular shape and their four sides are relatively parallel, it is easier to maintain stability during installation.

2. Shape to meet a specific space

Because rectangular tubes have a rectangular shape, their edges can better fit the shape of a wall or other structure. This makes rectangular tubes more suitable in scenarios where a compact layout is required, such as the routing of wires and cables.

3. Resistant to bending and compression, corrosion resistant

Rectangular steel pipe has excellent bending resistance, compression resistance and corrosion resistance to ensure the stability and safe operation of the application.

Disadvantages of Rectangular Steel Tubes

1. Relatively sharp edges

Rectangular steel pipes have relatively sharp edges, so they are prone to stress concentrations during bending, which can lead to pipe rupture.

2. High cost

Rectangular steel pipe production process requires more processes. The cost of rectangular steel pipe is higher than that of round steel pipe. Especially in the "first round and then square" molding process, square rectangular steel pipe directly than round steel pipe more than a molding process.

Rectangular Steel Pipe Applications

1. Industrial

Rectangular steel tubes are widely used in the industrial field, especially in the fields of machinery manufacturing, automation equipment and high-tech industry. Meanwhile, rectangular steel tubes can also be used as the support structure of high-precision instruments to ensure the precision and stability of the instruments.

2. Construction

Rectangular steel pipe is also widely used in the construction field for building structures, bridges, tunnels and so on. With strong bending strength and corrosion resistance, rectangular steel pipe is suitable for constructing important building and infrastructure projects. In the construction of bridges and tunnels, rectangular tubes are used as the main load-bearing material, which can withstand greater pressure and load with high safety and durability.

3. Transportation

In the field of transportation, rectangular tubes also have a wide range of applications. For example, isolation railings, road lighting poles and sign posts for highways and bridges can be made from rectangular steel tubes.

Shaped Steel Pipe

Shaped steel pipe is a general term for steel pipes with cross-section shapes other than round, square and rectangular.

Advantages of Shaped Steel Pipe

1. Large moment of inertia and section modulus

2. Large bending and torsion capacity

3. Can greatly reduce the weight of the structure, saving steel

Disadvantages of Shaped Steel Pipe

1. High production costs

Shaped tubes generally require customization, which is demanding in terms of production process and long lead time. The cost of producing a shaped tube is much higher than ordinary square and round tubes.

2. Difficult construction

Irregular steel pipes are mostly special shaped steel pipes, which increase the difficulty and risk of construction. For example, Yuantai Delun has customized 2 irregular octagonal pipes for the Ferris wheel project of a famous amusement park in China. The two giant supports of the Ferris wheel are two irregular octagonal tubes, which are several times more difficult to construct than ordinary steel tubes.

Application of Shaped Steel Pipe

With the development of society, the application of shaped steel pipe is more and more extensive. The common application scenarios are as follows.

1. Machinery industry

In the machinery industry, profiled steel pipe is widely used in the manufacture of various mechanical equipment. For example, some mechanical equipment components need to withstand high temperature, high pressure, friction and other harsh environments, then you can use profiled tube to manufacture these parts.

In addition, the structure of some mechanical equipment is more complex, need to use profiled tube to adapt to different space and structure.

2. Automotive industry

The automotive industry is an important area for the application of profiled tubes. In automobiles, profiled tubes are widely used in the manufacture of frames, bodies, engines and other parts. Due to the complex structure of automobiles, it is necessary to use a variety of different shapes of profiled tubes to meet different needs. For example, U-shaped profiled tubes can be used to manufacture the body of an automobile, while square profiled tubes can be used to manufacture the engine of an automobile.

3. Construction industry

In the construction industry, profiled tubes are widely used in the structure of buildings. For example, the structure of some high-rise buildings requires the use of square pipe profiles to enhance their strength and stability. In addition, the exterior walls of some buildings also need to use profiled tubes to create different shapes and structures.

4. Aerospace industry

As a high-performance metal material, shaped tubes are widely used in the manufacture of aerospace products. For example, some aircraft structures require the use of square tube profiles to increase their strength and stability, while some rocket structures require the use of round tube profiles to create more precise sizes and shapes.

5. Electronics industry

In the electronics industry, profiled tubes are also widely used in the manufacture of various electronic products. For example, the outer shell of some electronic products need to use square tube profile to manufacture, while the internal structure of some electronic products need to use round tube profile to manufacture.

In short, there are a wide variety of profiled tubes to meet the needs of different industries. In various industries, profiled tubes play an important role and provide a reliable guarantee for the quality and performance of products.

Fourth, the steel pipe according to the surface coating to points, can be divided into black pipe, pre-galvanized steel pipe, hot-dip galvanized steel pipe, zinc-aluminum-magnesium coated steel pipe, anticorrosive heat preservation steel pipe and so on.

Black Steel Pipe

The general state of steel pipe from the factory is called black steel pipe, the surface is not otherwise treated. It is different from galvanized steel pipe. Black carbon steel pipe is different from black alloy steel pipe, which has other alloy elements.

Advantages of Black Steel Pipe

Low cost

Black steel pipe is a little less expensive compared to galvanized or coated steel pipe.

Delivery Fast

The delivery cycle of black steel pipes is faster than that of hot-dip galvanized steel pipes, etc.

Disadvantages of Black Steel Pipe

Not corrosion-resistant

Black steel pipe has poor corrosion resistance because it is not hot-dip galvanized, or surface coated. When encountering a humid environment, black pipe will rust quickly.

The Application of Black Steel Pipes

Black steel pipes are widely used in various industries such as machinery, construction, petroleum, chemical, and power. In construction engineering, black steel pipes are commonly used to build supports, bridges, foundations, etc; In the field of mechanical processing, black steel pipe parts are usually used to make bearings, tires, etc.

Pre Galvanized Steel Pipe

Pre galvanized steel pipes are steel pipes directly processed from galvanized strips. So pre galvanized steel pipes are sometimes referred to as galvanized strip steel pipes.

Advantages of Pre Galvanized Steel Pipes

1. Beautiful appearance

The appearance of pre galvanized steel pipes is smooth and flat. Compared to black pipes and hot-dip galvanized steel pipes, pre galvanized steel pipes have a more beautiful appearance.

2. Corrosion resistance

Pre galvanized steel pipes have a zinc layer on their surface for protection, making them less susceptible to oxidation, corrosion, and rust. Compared to black pipes, they are more corrosion-resistant.

3. Simple construction

Pre galvanized steel pipes do not require additional anti-corrosion treatment during construction and can be directly installed and used for convenience and speed.

4. Cost savings

The price of pre galvanized steel pipes is slightly higher than that of ordinary steel pipes (but lower than hot-dip galvanized steel pipes), which can provide a longer service life and better usage effect, thus having good economic practicality.

Disadvantages of Pre Galvanized Steel Pipes

1. Limited thickness

The thickness of pre galvanized steel pipes is limited because raw materials such as pre galvanized steel coils or pre galvanized steel plates are not too thick.

2. Limited caliber

The diameter of pre galvanized steel pipes is also limited, and in general, the circumference of the steel pipe will not exceed 800mm.

3. Limited lifespan

The zinc layer thickness of pre galvanized steel pipes is not too thick due to the raw material. Therefore, compared with hot-dip galvanized steel pipes, the lifespan of pre galvanized steel pipes is not as long as that of hot-dip galvanized steel pipes.

Application of Pre Galvanized Steel Pipes

1. In the field of architecture

Pre galvanized steel pipes are widely used in the field of construction for pipeline systems such as water supply and drainage, heating, and air conditioning, as well as for the production of structural components such as building curtain walls, roofs, and exterior walls.

2. Transportation field

Pre galvanized steel pipes are mainly used in the transportation field for the production of structural components such as bridges, highways, railways, as well as the manufacturing of rail transit vehicles such as subways and light rails.

3. Mechanical field

Pre galvanized steel pipes are widely used in the mechanical field in hydraulic and pneumatic transmission, as well as in the production of structural components for mechanical equipment.

4. Chemical industry

Pre galvanized steel pipes are mainly used in the manufacturing and anti-corrosion treatment of chemical pipelines, storage tanks, reactors and other equipment in the chemical industry.

5. Electricity field

Pre galvanized steel pipes are mainly used in the manufacturing and anti-corrosion treatment of transmission line towers, conductors, insulators and other equipment in the field of power.

Hot Dip Galvanized Steel Pipe

Hot dip galvanized steel pipe is a steel pipe made by hot-dip galvanizing black steel pipes.

Advantages of Hot-Dip Galvanized Steel Pipes

1. Corrosion resistance

The corrosion resistance of hot-dip galvanized steel pipes is very good because the zinc layer of hot-dip galvanized steel pipes is particularly thick. Some hot-dip galvanized steel pipes are several times thicker than pre galvanized steel pipes. Therefore, the corrosion resistance of hot-dip galvanized pipes can be better than any type of coated steel pipe.

2. Unrestricted specifications

The raw materials for hot-dip galvanized steel pipes can be square black pipes, rectangular black pipes, circular black pipes, spiral welded pipes, straight seam steel pipes, seamless steel pipes, etc. Therefore, regardless of the diameter, wall thickness, length, as long as the zinc pool is large enough, hot-dip galvanized steel pipes can be made into any specification in principle.

Disadvantages of Hot-Dip Galvanized Pipes

1. High cost

Due to the surface hot-dip galvanizing treatment, the zinc layer of hot-dip galvanized steel pipes is relatively thick, which leads to an increase in the processing cost of hot-dip galvanized steel pipes.

2. The wall thickness should not be too thin

The wall thickness of hot-dip galvanized steel pipes should not be too thin, as too thin a wall thickness can easily lead to galvanizing failure or deformation of the steel pipe.

Application of Hot-Dip Galvanized Steel Pipes

1. Construction field

Hot dip galvanized steel pipes, as important building materials, are mainly used in construction, bridges, highway guardrails, tunnels, water conservancy engineering and other occasions. Hot dip galvanized pipes can withstand significant pressure and weight, and have good corrosion resistance, making them suitable for long-term use in harsh environments.

2. In the field of transportation

Hot dip galvanized steel pipes are generally used to manufacture automotive exhaust pipes, bicycle frames, ship accessories, etc. They have the characteristics of being lightweight, sturdy, and wear-resistant, and can effectively prevent rust and corrosion.

3. Oil and gas industry

Hot dip galvanized steel pipes are important tools for oil and gas extraction, processing, and transportation. They not only have good corrosion resistance, but also can withstand high temperature and high pressure. In addition, hot-dip galvanized steel pipes are also used in the oil and gas industry to manufacture equipment such as tanks, pipelines, and valves.

4. Chemical industry

Hot dip galvanized steel pipes are also widely used in the chemical industry. They can be used to manufacture equipment such as storage tanks, pipelines, reactors, and heat exchangers, with good corrosion resistance and high temperature resistance.

Zinc Aluminum Magnesium Coated Steel Pipes

Zinc aluminum magnesium steel pipe refers to a steel pipe made by forming, welding, and processing zinc aluminum magnesium strip steel. People generally believe that zinc aluminum magnesium steel pipes can replace pre galvanized steel pipes in the future.

Advantages of Zinc Aluminum Magnesium Steel Pipe

1. Corrosion resistance

The surface of zinc aluminum magnesium steel pipes is coated with three types of alloys, zinc aluminum magnesium. Therefore, the corrosion resistance of zinc aluminum magnesium steel pipes is higher than that of ordinary pre galvanized steel pipes, and their service life is also longer than that of pre galvanized steel pipes.

2. Self repair

After being cut, zinc aluminum magnesium steel pipes will form an anti oxidation film on the cutting surface, so people don't have to worry about rusting, corrosion, etc. on the cutting surface.

3. Economically practical

Compared to stainless steel pipes, zinc aluminum magnesium steel pipes have a significant cost advantage.

Disadvantages of Zinc Aluminum Magnesium Steel Pipe

1. High cost

The cost of zinc aluminum magnesium steel pipes is higher than that of ordinary black steel pipes due to the addition of a galvanized aluminum magnesium coating process on the surface of the steel pipes.

2. Slightly poor cutting performance

The zinc aluminum magnesium coating on zinc aluminum magnesium steel pipes is relatively hard and requires higher cutting equipment.

The Application of Zinc Aluminum Magnesium Steel Pipes

1. Construction field

Zinc aluminum magnesium square tubes can be used in support, beams, columns, trusses and other parts of building structures. It has the characteristics of high strength, corrosion resistance, good seismic resistance, and convenient construction, which can improve the stability and safety of buildings.

2. The automotive industry

Zinc aluminum magnesium square tubes can be used in the manufacturing of car bodies and chassis. It has high strength and corrosion resistance, which can improve the overall quality and durability of the car.

3. Aerospace field

Zinc aluminum magnesium square tubes can be used in the manufacturing of aerospace equipment such as airplanes and rockets. It has the characteristics of lightweight, high strength, and high corrosion resistance, which can reduce equipment weight and improve its performance.

4. Other fields

Zinc aluminum magnesium square tubes can also be applied in fields such as marine engineering, chemical equipment, and railway equipment. Their specific applications in these fields require further development and research.

Anti-corrosion heat preservation steel pipe

Anti corrosion steel pipes and insulation steel pipes are two major categories of products, referring to steel pipes that have undergone anti-corrosion and insulation treatment.

Advantages of Anti-corrosion and Insulation Steel Pipes

Anti corrosion and insulation steel pipes have much better corrosion resistance and insulation performance than ordinary steel pipes.

Disadvantages of Anti-corrosion Insulation Pipes

The anti-corrosion and insulation steel pipes undergo additional surface anti-corrosion and insulation treatment, so the anti-corrosion and insulation steel pipes are higher than ordinary steel pipes.

Application of Anti-corrosion and Insulation Pipes

1. Municipal engineering

Anti corrosion insulation pipes are suitable for pipeline applications in high-rise buildings such as water supply, drainage, heating network, water supply engineering, and gas transportation.

2. Oil

Anti corrosion insulation pipes are used in process pipelines for transporting corrosive media in industries such as petroleum transportation pipelines, chemical pharmaceuticals, printing and dyeing.

3. Sewage treatment

Anti corrosion and insulation pipes can be used as sewage treatment discharge pipes, sewage pipes, and pipelines in biological pool anti-corrosion engineering.

4. Agriculture

Anti corrosion and insulation steel pipes can be used as agricultural irrigation pipes, deep well pipes, drainage pipes, and other pipeline applications.

Fifthly, steel pipes can be classified according to standards, including American standard steel pipes, national standard steel pipes, European standard steel pipes, Australian standard steel pipes, Japanese standard steel pipes, printed standard steel pipes, Russian standard steel pipes, Canadian standard steel pipes, and so on.

Countries around the world have their own national standard steel pipes, including American standard steel pipes, Chinese standard steel pipes, European standard steel pipes, Australian standard steel pipes, Japanese standard steel pipes, Indian standard steel pipes, Russian standard steel pipes, and Canadian standard steel pipes. These standards represent the regulations and standardization requirements of different countries for the production and application of steel pipes.

American Standard Steel Pipe

American standard steel pipe refers to a unified term for steel pipes that comply with the corresponding national steel pipe standards in the United States. Common American standard steel pipes include ASTM A500 steel pipes, ASTM A53 steel pipes, ASTM A106 steel pipes, and so on.

Advantages of American Standard Steel Pipes

American standard steel pipes have good strength and corrosion resistance in use.

Disadvantages of American Standard Steel Pipes

American standard steel pipe: High cost and limited applicability.

Chinese Standard Steel Pipes

Chinese standard steel pipe refers to a unified term for steel pipes that comply with the corresponding national steel pipe standards in China. Common Chinese standard steel pipes include GB/T3091 steel pipes, GB/T9711 steel pipes, GB/T3094 steel pipes, etc.

The advantages of Chinese Standard Steel Pipes

China's national standard steel pipes have advantages such as mature manufacturing technology, stable and reliable quality, relatively complete size specifications, relatively wide selection range, relatively low cost, and fast delivery time.

Disadvantages of Chinese Standard Steel Pipes

Chinese standard steel pipes: Due to varying degrees of quality control by steel pipe factories, there may be a small amount of relatively unstable quality.

The Application of Chinese Standard Steel Pipes

The application of Chinese standard steel pipes is particularly widespread, and the presence of Chinese standard steel pipes can be seen in almost all industrial, construction, and chemical industries.

European Standard Steel Pipes

European standard steel pipes refer to the general term for steel pipes that comply with relevant European steel pipe standards. Common European standard steel pipes include EN10210 steel pipes and EN10219 steel pipes.

Advantages of European Standard Steel Pipes:

The production process of European standard steel pipes is strict, with excellent quality, suitable for high-pressure and high-temperature environments.

Disadvantages of European Standard Steel Pipes

European standard steel pipes: they are expensive and have a long production cycle.

The Application of European Standard Steel Pipes

Construction, oil, natural gas, chemicals, machinery manufacturing, and so on.

Australian Standard Steel Pipes

Australian standard steel pipes refer to the general term for steel pipes that comply with relevant Australian national steel pipe standards. Common Australian standard steel pipes include Australian standard seamless steel pipes AS1163-C350L0, AS 1074 steel pipes, and so on.

The Advantages of Australian Standard Steel Pipes

Australian standard steel pipes have high durability and reliability, and are suitable for use in complex climate environments.

Disadvantages of Australian standard steel pipes

Australian standard steel pipe: It has a high cost and is not suitable for large-scale projects.

The Use of Australian Standard Steel Pipes

The Australian standard square steel pipe can be used for building truss structures, building columns and wall structures, while the Australian standard circular steel pipe can be used for conveying generally lower pressure fluids such as water, gas, air, oil, and heating steam.

Japanese Standard Steel Pipe

Japanese standard steel pipes refer to steel pipes that comply with relevant Japanese national steel pipe standards. Common Japanese standard steel pipes include JIS G3466 steel pipe, JIS G3459 steel pipe, and so on.

Advantages of Japanese Standard Steel Pipes

Japanese standard steel pipe, precision machining, precise size, suitable for mechanical equipment manufacturing and other fields.

Disadvantages of Japanese Standard Steel Pipes

Japanese standard steel pipe: The price is relatively high and the scope of application is limited.

Application of Japanese Standard Steel Pipes

Building structures, mechanical components, high-strength structural components, pressure vessels, etc

Indian Standard Steel Pipe

Indian standard steel pipes refer to the general term for steel pipes that comply with relevant Indian national steel pipe standards. Common Indian standard steel pipes include ISI 1544-1962 steel pipes, IS 17876:2022 steel pipes, etc.

Advantages of Indian standard steel pipes

Indian standard steel pipes are suitable for civil applications such as water supply and natural gas transportation, with lower costs.

Disadvantages of Indian Standard Steel Pipes

Indian Standard steel pipes: The quality varies and should be carefully selected.

Applications of Indian Standard Steel Pipes

The application of Indian standard steel pipes is common in fields such as construction, chemical engineering, and mechanical manufacturing.

Russian Standard Steel Pipes

Russian standard steel pipes refer to the general term for steel pipes that comply with relevant Russian national steel pipe standards. Common Russian standard steel pipes include GOST 8732-78 steel pipes, GOST 8731-74 steel pipes, GOST 3262-75 steel pipes, etc.

Advantages of Russian Standard Steel Pipes

Russian standard steel pipes have high durability and strength, and are suitable for use in extremely cold climates.

Disadvantages of Russian Standard Steel Pipes

Russian standard steel pipe: The price is relatively high and not suitable for low-cost projects.

The application of Russian Standard Steel Pipes

Russian standard steel pipes are widely used in many fields such as fluid transportation and industrial manufacturing.

Canadian Standard Steel Pipes

Canadian standard steel pipes refer to the general term for steel pipes that comply with relevant Canadian national steel pipe standards. Common Canadian standard steel pipes include Z245.1-95 pipeline pipes, CAN/CSA-G40.20 steel pipes, etc.

Advantages of Canadian Standard Steel Pipes:

Canadian standard steel pipes, with advanced manufacturing technology and reliable quality, are widely used in the fields of oil and natural gas transportation.

Disadvantages of Canadian Standard Steel Pipes:

Canadian standard steel pipe: relatively expensive, suitable for projects that require high-quality products.

Application of Canadian Standard Steel Pipes:

Canadian standard steel pipes are widely used in fields such as construction, oil, natural gas, pipeline transportation, and mechanical manufacturing, meeting the needs of steel pipe products in different engineering projects.

Sixth, steel pipes can be divided into structural steel pipes and fluid steel pipes according to their purpose. Common structural steel pipes are divided into building structural steel pipes, mechanical structural steel pipes, marine steel pipes, etc. Fluid steel pipes are further divided into petroleum steel pipes, natural gas steel pipes, water pipes, etc.

Steel Pipes For Building Structures

Steel pipes for building structures are a common type of building pipeline material, widely used in steel structures, prefabricated steel structures, steel beams, steel supports, steel ground piles, and other building scenarios. According to different uses, steel pipes can be subdivided into hot-dip galvanized structural steel pipes, bridge structural steel pipes, underwater platform structural steel pipes, underground structural steel pipes, green building steel pipes, and special building structural steel pipes.

Advantages Of Steel Pipes In Building Structures:

Steel pipes for building structures: With high strength and stability, they are suitable for supporting projects such as buildings and bridges.

Disadvantages Of Steel Pipes In Building Structures:

Steel pipes for building structures: They are relatively heavy and costly.

The Application Of Steel Pipes In Building Structures

Steel pipes for building structures are widely used in various construction and bridge projects;

Mechanical structural steel pipes

Mechanical structural steel pipes refer to steel pipes used in large quantities in the mechanical manufacturing industry.

Advantages Of Mechanical Structural Steel Pipes

Mechanical structural steel pipe: With good processing performance, it is suitable for manufacturing mechanical components and engineering structures.

Disadvantages Of Mechanical Structural Steel Pipes

Mechanical structural steel pipes: require cutting and welding processing, with high processing costs.

The Application Of Mechanical Structural Steel Pipes

Mechanical structural steel pipes are widely used in the manufacturing and processing of mechanical equipment;

Marine steel pipes

Marine steel pipes refer to steel pipes widely used in the shipbuilding industry.

The Advantages Of Marine Steel Pipes

Marine steel pipes: have good corrosion resistance and meet the requirements of ship construction.

Disadvantages Of Marine Steel Pipes

Marine steel pipes: have a high cost and require strengthened anti-corrosion measures.

The Application Of Marine Steel Pipes

Marine steel pipes are used in ship construction and marine engineering;

Petroleum steel pipe

Petroleum steel pipes refer to the general term for steel pipes used in scenarios such as oil transportation, oil refining, and oil extraction.

Advantages Of Petroleum Steel Pipes

Petroleum steel pipes: resistant to high pressure and corrosion, suitable for petroleum drilling, production, and transportation.

Disadvantages Of Petroleum Steel Pipes

Petroleum steel pipes: have high costs and high material requirements.

Application Of Petroleum Steel Pipes

Petroleum steel pipes are mainly used for oil extraction and transportation;

Natural Gas Steel Pipes

Natural gas steel pipes refer to the general term for steel pipes used in the field of natural gas transportation.

Advantages Of Natural Gas Steel Pipes

Natural gas steel pipes: have good sealing and pressure resistance, and are safe and reliable.

Disadvantages Of Natural Gas Steel Pipes:

Natural gas steel pipes: require regular inspection and maintenance, with high costs.

The Application Of Natural Gas Steel Pipes

Natural gas steel pipes are used for transporting natural gas;

Water Supply Steel Pipes

Water supply steel pipes refer to the general term for steel pipes used in urban pipeline construction to transport drinking water and other wastewater.

Advantages Of Water Supply Steel Pipes

Water supply steel pipe: with good corrosion resistance, suitable for urban water supply and drainage systems.

Disadvantages Of Water Supply Steel Pipes

Water supply steel pipe: Anti corrosion treatment is required for wastewater treatment, and maintenance costs are high. Regular replacement is required.

Application Of Water Supply Steel Pipes:

Steel pipes are used for urban water supply and drainage systems.

Seventh, steel pipes are classified according to size, and are further divided into small diameter steel pipes, medium diameter steel pipes, and large diameter steel pipes. Steel pipes with different diameters have different uses and characteristics in various fields.

Small Diameter Steel Pipe

Usually, we call the steel pipe with outside diameter less than or equal to 89mm as small diameter steel pipe.

Advantages Of Small Diameter Steel Pipes:

Small diameter steel pipe: lightweight, low-cost, suitable for use in narrow spaces or places that require bending.

Disadvantages Of Small Diameter Steel Pipes:

Small diameter steel pipe: With a small load-bearing capacity, it is not suitable for conveying large flow rates of liquids or gases.

Application Of Small Diameter Steel Pipes:

Small diameter steel pipe: With a small load-bearing capacity, it is not suitable for conveying large flow rates of liquids or gases.

1. Construction industry

Small diameter steel pipes are mainly used in building components, columns, beams, bridges, etc. Due to their excellent corrosion resistance, high strength, and good plasticity, they are widely used in the construction of high-rise buildings and large-span steel structures.

2. Mechanical Industry

Small diameter steel pipes are an indispensable component in machine tool processing, with the advantages of being able to withstand large pressures, good wear resistance, and long service life. Small diameter steel pipes can also be used as accessories for mechanical parts, such as shaft sleeves, wheel hubs, wheel axles, and so on.

3. The Automotive, Motorcycle, And Bicycle Industries

Small diameter steel pipes are widely used in the manufacturing of automobiles, motorcycles, bicycles, such as frames, exhaust pipes, oil pipes, and so on. Small diameter steel pipes have become an essential material in these industries due to their lightweight, high strength, and strong anti-corrosion properties.

Medium Diameter Steel Pipe

Usually, we refer to steel pipes with an outer diameter greater than 89mm but less than or equal to 499mm as medium diameter steel pipes.

Advantages Of Medium Diameter Steel Pipes

Medium diameter steel pipe: It has a wide range of applications, high strength and bearing capacity, and can meet most common engineering needs.

Disadvantages Of Medium Diameter Steel Pipes

Medium diameter steel pipe: In some large-scale projects, it may not meet the demand and larger diameter steel pipes need to be selected.

Application Of Medium Diameter Steel Pipes

Medium diameter steel pipes are widely used in fields such as construction, oil, natural gas, aviation, aerospace, shipbuilding, and heavy industry. Medium diameter steel pipes are commonly used in general engineering projects such as construction and municipal engineering;

Large Diameter Steel Pipe

Large diameter steel pipes usually refer to steel pipes or pipes with an outer diameter greater than or equal to 500mm.

Advantages Of Large-Diameter Steel Pipes

Large diameter steel pipe: With strong load-bearing capacity, it is suitable for transporting large liquids or gases and has good sealing properties.

Disadvantages Of Large Diameter Steel Pipes

Large diameter steel pipe: The cost is relatively high, and installation and maintenance require more manpower and material costs.

Application Of Large-Diameter Steel Pipes

Large diameter steel pipes are widely used in construction projects, transportation of oil, natural gas, water conservancy projects, and heavy machinery manufacturing.

Summary: The diameter of steel pipes determines their application range and bearing capacity in different engineering projects. When selecting steel pipes, it is necessary to choose the appropriate diameter based on specific engineering requirements and requirements to ensure the quality and safety of the project.

Eighth, steel pipes are classified according to precision, and are further divided into precision steel pipes and ordinary steel pipes. Precision steel pipes and ordinary steel pipes are common metal pipes that play important roles in the fields of engineering and manufacturing. Although they are all pipeline materials used for transporting fluids and gases, they have different characteristics and uses in some specific applications.

Precision steel pipe

Precision steel pipe is a high-precision pipe material that has been processed by cold drawing or hot rolling.

Advantages Of Precision Steel Pipes

Precision steel pipe is a high-precision pipe material that has been processed by cold drawing or hot rolling.

1.Accurate Size

Precision steel pipes have highly accurate outer diameter and wall thickness, making them suitable for engineering projects with strict size requirements.

2.Surface Smoothness

Good surface quality, suitable for occasions with high requirements for internal surface smoothness.

3.Good Bending Resistance:

Has strong bending resistance and is suitable for situations that require bending.

Disadvantages Of Precision Steel Pipes:

1.High Cost

The production process of precision steel pipes requires high requirements, therefore the cost is relatively high.

2.Restricted Use:

Mainly used in fields with strict requirements for size and surface, with less demand for general engineering projects.

The Use Of Precision Steel Pipes

Precision steel pipes are widely used in the fields of automobiles, motorcycles, electric vehicles, petrochemicals, power, ships, aerospace, bearings, pneumatic components, seamless steel pipes for medium and low pressure boilers, and can also be applied to steel sleeves, bearings, hydraulic, mechanical processing, and other fields!

Ordinary Steel Pipe

The ordinary steel pipes here are compared to precision steel pipes, and there is a certain tolerance range for the size specifications of ordinary steel pipes, which are also a type of steel hollow section.

Advantages Of Ordinary Steel Pipes

1. Low Cost:

The production cost of ordinary steel pipes is relatively low, making them suitable for general engineering projects that require large-scale use.

2. Widely applicable:

Suitable for general engineering projects, such as building structures, hydraulic engineering, HVAC equipment, and other fields.

3. Good welding performance:

Ordinary steel pipes are easy to weld and easy to install.

Disadvantages Of Ordinary Steel Pipes:

1. General dimensional accuracy:

Compared to precision steel pipes, ordinary steel pipes have lower dimensional accuracy.

2. Surface Smoothness Is Average:

The roughness of the inner and outer surfaces is relatively high, and the quality of the inner surface is average.

Application of ordinary steel pipes

Ordinary steel pipes are mainly used in large-scale general engineering projects such as building structures, municipal pipelines, and oil and gas transportation.

In summary, precision steel pipes have advantages in size and surface quality, and are suitable for precision fields with high quality requirements; Ordinary steel pipes are low-cost and widely used, playing an important role in general engineering projects. When selecting steel pipes, it is necessary to make a reasonable selection based on specific engineering requirements and uses.

Ninth, steel pipes can be divided into cold formed steel pipes and hot formed steel pipes according to the heat treatment method. Cold formed steel pipes and hot formed steel pipes are two common steel pipe production processes. They have their own advantages and characteristics in both engineering and manufacturing fields, and are suitable for different application scenarios.

Cold Rolled Steel Pipe

The so-called cold rolled steel pipe refers to a steel pipe that is formed into the desired shape and size by applying pressure at room temperature.

Advantages Of Cold Rolled Steel Pipes

1. Accurate Size

Cold rolled steel pipes have high dimensional accuracy and are suitable for engineering projects with strict size requirements.

2. Surface Smoothness:

Good surface quality, suitable for occasions with high requirements for internal surface smoothness.

3. The Molding Process Is Simple

Cold forming process is simpler and has lower cost compared to hot forming.

Disadvantages Of Cold Formed Steel Pipes

Cold forming process is simpler and has lower cost compared to hot forming.

1. Low Production Efficiency

The production efficiency of cold forming process is relatively low.

2. Restricted By Usage

Mainly suitable for the production of pipes with small diameter and thin wall thickness.

The Application Of Cold Formed Steel Pipes

Cold formed steel pipes are mainly used in high-precision requirements in fields such as automotive manufacturing, aerospace, and precision machinery.

Hot Rolled Steel Pipe

Hot formed steel pipes refer to steel pipes that undergo plastic deformation and forming at high temperatures.

Advantages Of Hot Rolled Steel Pipes

High production efficiency: The hot forming process has high production efficiency.

Can process large-sized pipes: suitable for processing pipes with large diameters and wall thicknesses.

Wide molding range: suitable for the production of pipes of various shapes and specifications.

Remove internal stress.

Disadvantages Of Hot Rolled Steel Pipes

Surface quality is average: Due to high-temperature forming, the inner and outer surfaces have a relatively high roughness.

Application Of Hot Formed Steel Pipes

Hot formed steel pipes are mainly used in fields such as oil and gas transportation, chemical equipment, boiler pipelines, etc., which have high requirements for pipe size and pressure resistance.

Summary: Cold formed steel pipes are suitable for precision fields with high requirements for size and surface quality, while hot formed steel pipes are suitable for the production of pipes with large diameter and thickness. They play important roles in both engineering and manufacturing fields. When selecting steel pipes, it is necessary to make a reasonable selection based on specific engineering requirements and uses.

Tenth, steel pipes can be classified according to wall thickness, including thin-walled steel pipes, medium thick walled steel pipes, thick walled steel pipes, and extra thick walled steel pipes. Thin walled steel pipes, medium thick walled steel pipes, thick walled steel pipes, and extra thick walled steel pipes are common types of steel pipes, which have different applications and characteristics in the fields of engineering and construction.

Thin-Walled Steel Pipe

Usually, steel pipes with a wall thickness less than 3mm are referred to as thin-walled steel pipes. Some people also refer to steel pipes with a ratio of outer diameter to wall thickness greater than 20 as thin-walled steel pipes.

Advantages Of Thin-Walled Steel Pipes

Lightweight: Lightweight, suitable for occasions with low requirements for pipeline weight.

Low cost: The production cost is relatively low.

Easy to install: Due to its light weight, installation and handling are relatively easy.

Disadvantages Of Thin-Walled Steel Pipes

Low pressure resistance: Not suitable for use in pressure environments.

Limited corrosion resistance: weak adaptability to corrosive environments.

Application Of Thin-Walled Steel Pipes

Thin walled steel pipes are suitable for furniture, lightweight structures, decoration, and mechanical manufacturing fields.

Medium Thick Walled Steel Pipe

Middle wall steel pipe refers to a steel pipe with a wall thickness between 3mm and 16mm.

Advantages Of Medium Thick Walled Steel Pipes

Higher pressure bearing capacity: Compared to thin-walled steel pipes, medium thick walled steel pipes have higher pressure bearing capacity.

Good corrosion resistance: suitable for use in general corrosive environments.

Disadvantages Of Medium Thick Walled Steel Pipes

Heavy: Compared to thin-walled steel pipes, it is heavier.

High cost: The production cost is slightly higher than that of thin-walled steel pipes.

Application Of Medium Thick Walled Steel Pipes

Medium thick walled steel pipes are commonly used in fields such as building structures, shipbuilding, and automotive manufacturing.

Thick Wall Steel Pipe

Usually, we refer to steel pipes with a ratio of outer diameter to wall thickness less than 20 as thick walled steel pipes.

Advantages Of Thick Walled Steel Pipes

High strength: It has a high pressure bearing capacity.

Corrosion resistance: It has good corrosion resistance performance.

Disadvantages Of Thick Walled Steel Pipes

Heavy: Heavy in weight, requiring significant handling and installation techniques.

Application Of Thick Walled Steel Pipes

Thick walled steel pipes are suitable for use in fields such as oil and natural gas pipelines, high-pressure boilers, and fertilizer equipment.

Heavy Wall Pipe

Usually, we refer to steel pipes with a wall thickness greater than 40mm as extra thick walled steel pipes.

Advantages Of Super Thick Walled Steel Pipes

Extremely high pressure bearing capacity: used in high-pressure and ultra-high pressure situations.

Disadvantages Of Super Thick Walled Steel Pipes

Heavy weight, high price: high cost.

Application Of Super Thick Walled Steel Pipes

In situations with extremely high pressure conditions, such as nuclear power plants, aerospace and other fields.

Different types of steel pipes with different wall thicknesses have different characteristics and application scenarios in the fields of engineering and construction. Understanding these characteristics can help choose the appropriate type of steel pipe to meet engineering needs.

In short, there are various types of steel pipes and their applications are also very extensive. When purchasing steel pipes, it is best to consult professional personnel or contact the customer manager of Yuantai Derun.