What Are ERW Steel Pipes?

- Share

- publisher

- Tianjin Yuantai Derun Steel Pipe Group

- Issue Time

- Mar 1,2024

Summary

ERW steel pipes occupy an important position in global steel pipe applications. ERW steel pipes not only have excellent performance, but also have low cost, making them the best among all metal pipes.

Preface

ERW steel pipes, as a major category of steel pipe building materials, are widely used. As a steel pipe user, you will definitely not be too unfamiliar. This article provides an in-depth interpretation of the definition, production process, size, price, standards, and other aspects of ERW pipes. To gain a comprehensive understanding of the basics of ERW pipes, simply read this article.

What Are Erw Steel Pipes?(erw steel pipe meaning)

ERW steel pipe meaning is Electrical Resistance Weld steel pipe,ERW is an abbreviated form of Electrical Resistance Weld.ERW steel pipes are pipes formed by rolling steel coils and then welding them with high-frequency resistance. Their welds are parallel to the pipes, making them a very popular category of straight seam steel pipes.

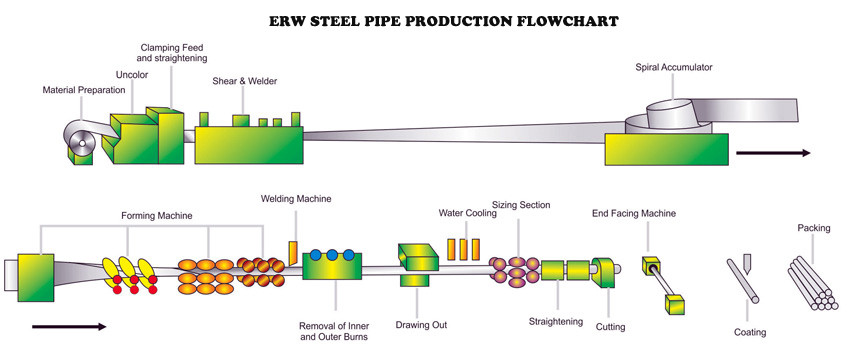

Erw Steel Pipe Manufacturing Process

1.Welding Process Of Erw Steel Pipe

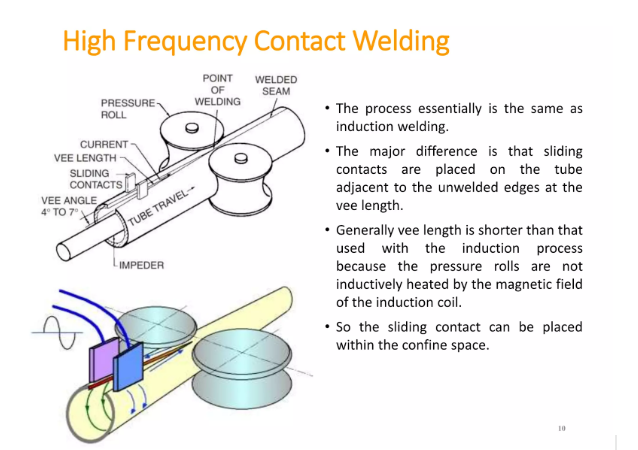

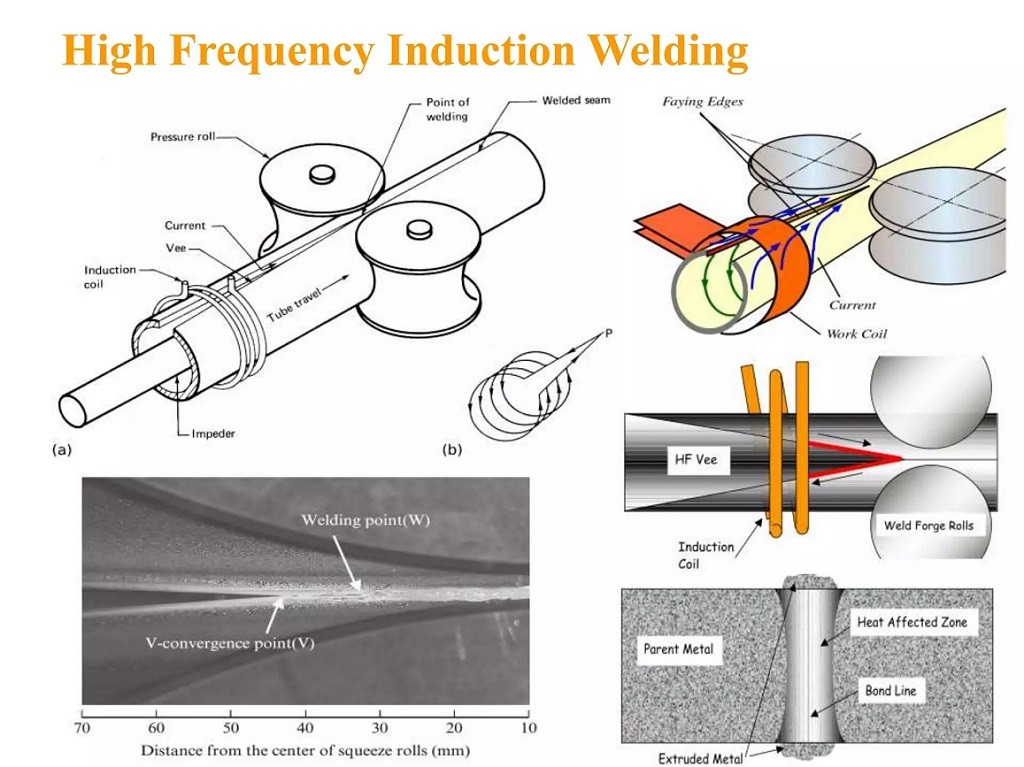

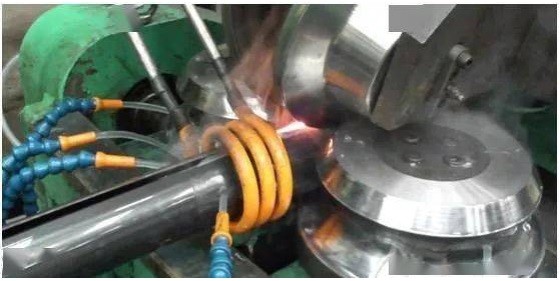

Straight seam high-frequency resistance welded pipe (ERW) is a hot rolled coil through the forming machine after molding, the use of high-frequency current skin effect and neighborhood effect, so that the edge of the billet heated and melted in the extrusion rollers under the action of the pressure welding to achieve the production. According to the different ways of feeding, ERW welded pipe can be divided into high-frequency contact welding and high-frequency induction welding.

High Frequency Contact Welding

High Frequency Induction Welding

2. Basic Principles Of High-Frequency Welding

The so-called high frequency refers to the high-frequency current frequency between 50KHz and 400KHz, which is relative to the 50Hz AC current frequency. When high-frequency current passes through a metal conductor, two peculiar effects are generated: skin effect and proximity effect. High frequency welding uses these two effects to weld steel pipes. So, what are these two effects?

2.1 Skin Effect

Do you know about the skin effect? When AC current passes through the same conductor at a certain frequency, the current density is not uniformly distributed across all cross-sections of the conductor, but mainly concentrated on the surface of the conductor. This is the so-called "skin effect". This means that the current has a higher density on the surface of the conductor, while the density inside the conductor is lower.

To quantify this effect, we usually use the depth of current penetration as a measure. The smaller the penetration depth value, the more obvious the skin effect. The penetration depth is directly proportional to the square root of the resistivity of the conductor, and inversely proportional to the square root of frequency and magnetic permeability. Simply put, the higher the frequency, the more concentrated the current is on the surface of the steel plate; The lower the frequency, the more dispersed the surface current will be.

Another point to note is that although steel is a conductor, its magnetic permeability decreases with increasing temperature. That is to say, as the temperature of the steel plate increases, its magnetic permeability will decrease, leading to a weakening of the skin effect.

2.2 Proximity Effect

Do you know about the proximity effect? When high-frequency current flows in opposite directions between two adjacent conductors, the current will concentrate and flow towards the edges of the two conductors that are close together. Even if there is a short path between two conductors, current will not flow along this short path. This effect is called the "proximity effect".

The proximity effect is actually caused by the dominant role of inductance in high-frequency currents. As the frequency increases and the distance between adjacent conductors decreases, the proximity effect becomes more pronounced. In addition, if a magnetic core is added around the adjacent conductor, the high-frequency current will be more concentrated on the surface of the workpiece.

These two effects are key to achieving high-frequency metal welding. The skin effect concentrates the energy of high-frequency current on the surface of the workpiece, while the proximity effect helps us control the route and range of current flow. The current speed is very fast, which can heat and melt adjacent steel plate edges in a short period of time, and then squeeze them tightly together. This is the working principle of high-frequency welding, simple and efficient.

ERW Pipe Benifits

ERW steel pipes have many advantages, mainly concentrated in the following aspects.

1.Fast production cycle

The production of ERW steel pipes is much faster than seamless steel pipes and LSAW steel pipes. If the production speed of ERW pipes is 5G, then the production speed of seamless steel pipes and LSAW steel pipes is 4G or 3G.

2.High dimensional accuracy

The dimensional accuracy of ERW steel pipes is higher than that of seamless steel pipes and LSAW steel pipes.

3.Surface aesthetics

Due to the fact that ERW steel pipes are welded from hot-rolled coils, their surfaces are smoother and smoother, and their wall thickness is also relatively uniform.

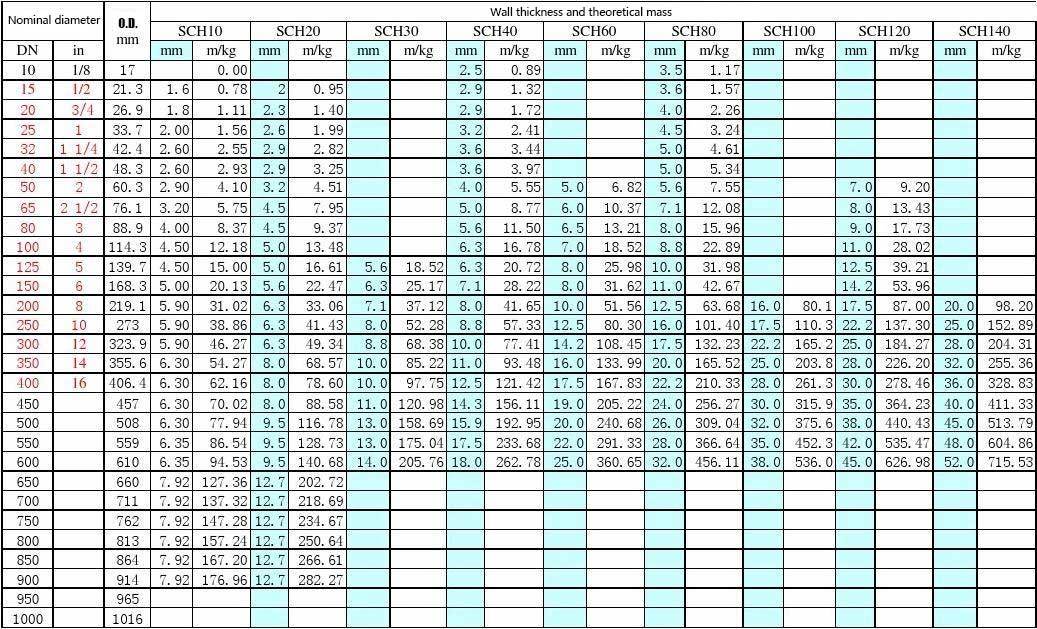

Under normal circumstances, the ERW steel pipe φ Can be obtained from ¼− 18 inches, the wall thickness range of ERW pipe is 0.5-20mm, and the length of ERW welded pipe can be customized, ranging from 0.5-24M. In the ERW steel pipe family, there are two particularly popular types of steel pipes: Schedule 40 ERW pipe and Schedule 80 ERW pipe.

Erw Steel Pipe Weight Chart

ERW Pipe HS Code 7306

Erw Steel Pipe Price

The price of ERW steel pipes is mainly influenced by the price of raw materials, followed by ocean freight, and finally by personnel costs. Usually, the price of ERW pipes is a fluctuating price, and the daily price is different from the daily price. Therefore, if you need to know the accurate price of ERW pipes, you need to contact the customer manager in a timely manner to provide you with a quotation.

Erw Steel Pipe Standards

The standards for ERW steel pipes include ASTM, API 5L, ASME, CE EN10210, EN10219, AS1153, DIN2240, JIS G3466, API 5L, ASTM A53B, ASTM A178, ASTM A500/501, ASTM A691, ASTM A252, ASTM A672, ASTM A135, and so on. The ASTM A53 standard is the most common among them. Let's take a look at some information about this standard.

1.What Is ASTM A53 Standard?

ASTM Specification A53 is a widely adopted international standard that specifies in detail the manufacturing requirements and specifications for seamless and welded steel pipes. These steel pipes come in two types: black and hot-dip galvanized, and are characterized by their nominal (average) wall thickness. These steel pipes are particularly suitable for various application scenarios, including winding, bending, flange manufacturing, and other special purposes.

In addition to the above characteristics, ASTM Specification A53 also specifies requirements for the dimensions, tolerances, mechanical properties, chemical composition, and non-destructive testing of steel pipes. These requirements ensure the quality and reliability of steel pipes, enabling them to perform excellently in various application scenarios. Meanwhile, these steel pipes are also suitable for welding operations and can meet some situations that require connection or repair.

Surface Treatment Of Erw Steel Pipe

ERW welded pipes have a wide range of applications, so what are the surface treatment methods for this type of steel pipe? With this question in mind, the editor has found the following 6 ways to handle ERW welded steel pipes. Each surface treatment method is designed to cope with different usage scenarios. Let me show you one by one.

1.Hot Dip Galvanizing

ERW galvanized pipe is a popular steel building material product among people. Not only is the surface highly corrosion-resistant, but the cost is also not very expensive. ERW galvanized steel pipe adopts the surface treatment method of hot-dip galvanizing. The surface treatment process of hot-dip galvanizing is as follows:

Black ERW tube → straightening → water washing → acid washing → rinsing → solvent application → drying → hot-dip galvanizing → external blowing → internal blowing → water cooling → inspection → passivation → label printing → packaging → shipment. The service life of hot-dip galvanized steel pipes can reach up to 30-100 years.

2.Oiling

In short distance transportation, we can apply oil to prevent ERW pipes from rusting.

3.Painting

ERW steel pipes are prone to rust when exposed to air for a long time, and painting can effectively prevent surface rust and moisture.

4. Anti Corrosion And Insulation

Due to the influence of some cold environments, we can also apply anti-corrosion and insulation treatment to ERW steel pipes. This can not only protect ERW steel pipes from cracking, but also prevent corrosion of the steel pipes from the external environment.

5.Blasting Treatment

The main purpose of shot blasting treatment for steel pipes is to remove rust. Shot blasting treatment refers to the use of a high-power motor to drive the rotation of blades, causing abrasives such as steel sand, steel shot, iron wire segment, minerals, etc. to spray and treat the surface of steel pipes under centrifugal force. On the one hand, all rust, oxides, and dirt are cleaned, and on the other hand, the steel pipes achieve the required uniform roughness under the strong impact and friction of abrasives.

6. Electrophoretic Coating Process

Do you know that electrophoretic coating is a special coating method. It first puts the steel pipe into the dielectric, and then through the process of electrolyzing ions, a special coating is evenly deposited on the surface of the steel pipe. This coating is like putting a protective coat on the steel pipe, which not only has a variety of colors but also good corrosion resistance. The most important thing is that there are no special requirements for the construction environment during this type of painting, which is very convenient. However, this painting process is relatively complex, so the cost will be slightly higher.

Erw Steel Pipe Use

ERW steel pipes are widely used in industries such as water engineering, petrochemical industry, chemical industry, power industry, agricultural irrigation, and urban construction. ERW tube is one of the twenty products in China.

Used for liquid transportation: water supply and drainage.

Used for gas transportation: coal gas, steam, liquefied petroleum gas.

Used for structural purposes: as a pile driving pipe, as a bridge; Pipes for docks, roads, building structures, etc.

In order to improve the service life of ERW welded pipes for oil and gas, surface treatment is usually required to facilitate the bonding between large-diameter straight seam steel pipes and layers.

Final Word:

ERW steel pipes occupy an important position in global steel pipe applications. ERW steel pipes not only have excellent performance, but also have low cost, making them the best among all metal pipes. Understanding the production process, size, price, and usage of ERW steel pipes is a necessary task for every steel pipe user. That's all for sharing this article. If you have any other questions, you can contact us immediately.

FAQ:

1.What is the difference between ERW & seamless pipe?

The biggest difference between ERW pipe and seamless steel pipe is that ERW welded pipe has a straight weld seam, while seamless steel pipe has no weld seam. Therefore, welded pipes may not have the same strength as seamless pipes under the same steel grade and size specifications.

2.What is the difference between MS pipe and ERW pipe?

MS pipe emphasizes low-carbon steel pipes more. ERW pipes emphasize that the forming method of steel pipes adopts high-frequency resistance welding.

3.What does ERW mean in welding?

ERW means Electric resistance welded.

4.What are the advantages of ERW tube?

ERW tubes have fast molding, short production cycles, and significant cost advantages. Outstanding performance. Widely used. Smooth appearance.