Characteristics, classification and performance parameters of structural steel pipes

- Share

- publisher

- Tianjin Yuantai Derun Steel Pipe Manufacturing Group Co., Ltd.

- Issue Time

- Mar 9,2023

Summary

Structural steel pipes include hot-rolled seamless steel pipes and welded steel pipes.

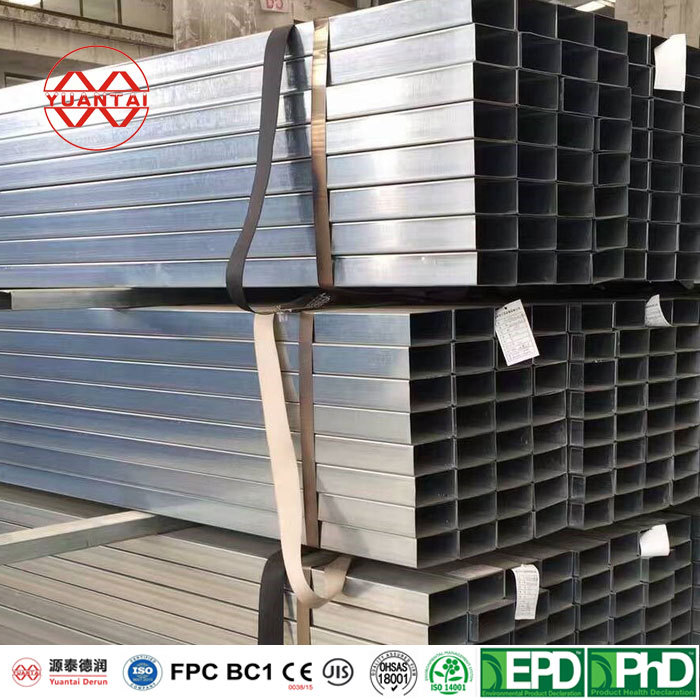

Steel pipe for structure

Structural steel pipes include hot-rolled seamless steel pipes and welded steel pipes. Seamless steel pipes for structures are divided into hot rolling (extrusion, expansion) and cold drawing (rolling) according to Seamless Steel Pipes for Structures (GB/T8162-2008). The outer diameter of hot-rolled steel pipe is 32-630mm, and the wall thickness is 2.5-75mm; The outer diameter of cold-drawn steel pipe is 5-200mm, and the wall thickness is 2.5-12mm. Welded steel pipe is made of steel plate or steel strip after being crimped and welded, which is divided into straight seam electric welded steel pipe and spiral welded steel pipe. The outer diameter of the longitudinally welded steel pipe is 5-508mm, and the wall thickness is 0.5-12.7mm, which should comply with the provisions of the longitudinally welded steel pipe (GB/T3793-2008). Welded steel pipe for low pressure fluid transmission is also known as general welded pipe, commonly known as black pipe. The specification is expressed in millimeters of nominal diameter, which should comply with the provisions of Welded Steel Pipe for Low Pressure Fluid Transmission (GB/T3091-2008).

Characteristics of structural steel pipe

Structural steel pipe is usually made of high-strength steel plate, and its features include:

1. High strength: Because of the use of high-strength steel, structural steel pipes have high strength and stiffness, and can withstand certain loads and vibrations.

2. Good corrosion resistance: the surface of structural steel pipe is subject to anti-corrosion treatment such as galvanizing or plastic spraying, which has good corrosion resistance and can be used for a long time in humid, corrosive and other environments.

3. Convenient construction: the structural steel pipe has high manufacturing accuracy, stable size, convenient installation and construction, saving a lot of labor and material costs.

4. Good plasticity: structural steel pipes can be cut, welded, bent and other processed according to needs, and can be made into various shapes and specifications to meet different building structural requirements.

5. Light weight: compared with the traditional concrete structure, the structural steel pipe has light weight, so it can reduce the overall quality of the building and reduce the bearing pressure of the foundation.

What are the classification of structural steel pipes?

Structural steel pipes can be divided into various types according to different classification standards. Here are some common classification methods:

1. Classification by use: steel pipes for building structures, steel pipes for machinery manufacturing, steel pipes for petroleum cracking, etc.

2. Classification by material: it can be divided into carbon structural steel pipe, alloy structural steel pipe, stainless steel structural steel pipe, etc.

3. Classified by production process: seamless steel pipe, spiral welded steel pipe, long welded steel pipe, etc.

4. Classification by shape: it can be divided into square steel pipe, rectangular steel pipe, round steel pipe, etc.

5. Classification according to wall thickness: it can be divided into thick-walled steel pipes, thin-walled steel pipes, etc.

6. Classification by diameter: it can be divided into large-diameter steel pipe, medium-diameter steel pipe, small-diameter steel pipe, etc.

7. Other classification: it can also be classified according to surface state and length.

What are the standards for structural steel pipes?

There are many standards for structural steel pipes. The following are some common standards:

1. GB/T 3091-2015 Welded Steel Pipe

2. GB/T 13793-2016 long itudinal longitudinally welded steel pipe

3. GB/T 8162-2018 Seamless Steel Pipe for Structure

4. GB/T 9711-2011 Petroleum and Natural Gas Industries - Steel Pipe for Transmission

5. ASTM A53/A53M-18 standard specification for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded and Seamless

6. ASTM A500/A500M-18 Standard Specification for Cold-Formed Welded and Seamless Carbon Steel Structural Tubing in Rounds and Shapes

7. EN 10210-1: 2006 Hot-rolled structural hollow section steel pipe

8. EN 10219-1: 2006 Cold formed structural hollow section steel pipe

9. JIS G3444-2006 Welded steel pipe for General Structural Purposes

10. JIS G3466-2019 square steel pipe, rectangular steel pipe and round steel pipe.

These standards have different application scope and requirements in different countries and regions.

What are the dimensions of structural steel pipes?

The size and specification of structural steel pipes are different according to different standards and requirements. The following are some common dimensions: 1 Square steel pipe: side length is 10mm-1000mm, wall thickness is 0.5mm-30mm. 2. Rectangular steel pipe: side length is 10mm-800mm, wall thickness is 0.5mm-30mm. 3. Round steel pipe: outer diameter is 6mm-1500mm, wall thickness is 0.5mm-120mm. 4. Stainless steel pipe: outer diameter is 6mm-630mm, wall thickness is 0.5mm-30mm. 5. Steel pipe for petroleum cracking: outer diameter is 60mm-830mm, wall thickness is 4mm-45mm. 6. Seamless steel pipe for structure: outer diameter is 21.3mm-660mm, wall thickness is 2.3mm-60mm. 7. Welded steel pipe: outer diameter is 17mm-610mm, wall thickness is 0.6mm-22mm. Of course, these data are only reference data, and the specific dimensions and specifications need to be determined according to the specific requirements and production standards.

What are the chemical properties, mechanical properties and physical parameters of structural steel pipes?

The chemical properties, mechanical properties and physical parameters of structural steel pipes vary with different materials, production processes and specifications. Here are some common situations:

1. Chemical properties: The main chemical components of structural steel pipes include carbon, silicon, manganese, sulfur, phosphorus and other elements. The content of these elements will affect the corrosion resistance, weldability, strength and other properties of structural steel pipes.

2. Mechanical properties: the mechanical properties of structural steel pipes mainly include tensile strength, yield strength, elongation, hardness and other indicators. These performances are often determined according to different standards and application requirements.

3. Physical parameters: the physical parameters of structural steel pipe include density, thermal expansion coefficient, thermal conductivity, specific heat capacity, etc. For example, the density of carbon structural steel pipe is about 7.85g/cm ³, The coefficient of thermal expansion is about 11.7 × 10 ^ - 6/℃, thermal conductivity is about 46.6W/(m · K), and specific heat capacity is about 0.46J/(g · ℃).

In general, the chemical properties, mechanical properties and physical parameters of structural steel pipes are very important indicators, and appropriate selection needs to be made according to specific application requirements.