2 x 5 Rectangular Tube: An Essential Structural Component

- Share

- Issue Time

- Oct 11,2023

Summary

In various industries, the demand for sturdy and versatile structural components is critical. One such component that has gained widespread usage is the 2 x 5 rectangular tube.

I. Introduction

In various industries, the demand for sturdy and versatile structural components is critical. One such component that has gained widespread usage is the 2 x 5 rectangular tube. This article explores the dimensions, applications, manufacturing process, advantages, and maintenance guidelines for this essential structural element.

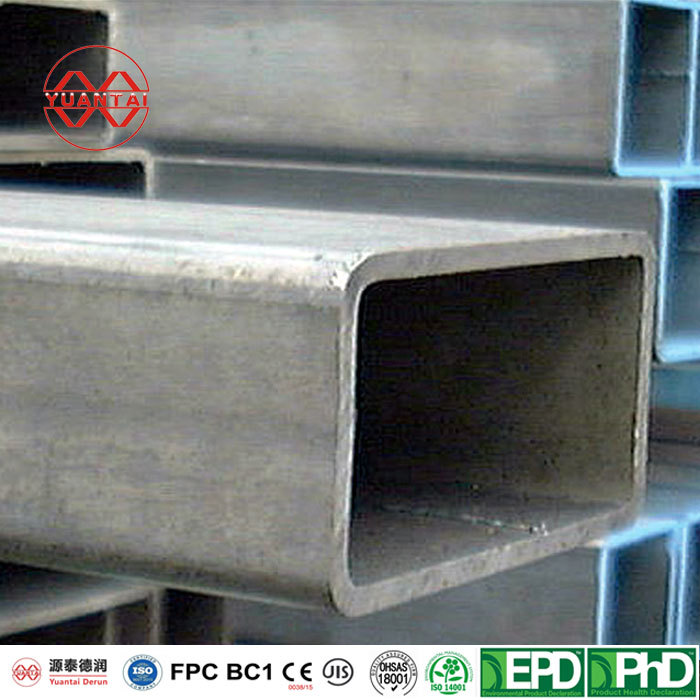

II. What is a 2 x 5 rectangular tube?

A 2 x 5 rectangular tube refers to a tubing component with a rectangular cross-section, featuring dimensions of 2 inches by 5 inches. These tubes are commonly made using materials like steel, aluminum, or stainless steel, depending on the specific application requirements.

III. Applications of 2 x 5 rectangular tubes

The applications of 2 x 5 rectangular tubes are incredibly diverse. They are extensively used in the construction industry for building frames, supports, and structures. Additionally, they find application in the manufacturing of machinery, automotive components, furniture, and even in the aerospace industry.

IV. Advantages of using 2 x 5 rectangular tubes

The utilization of 2 x 5 rectangular tubes provides several advantages over other structural components. Firstly, their rectangular shape offers great stability and resistance to bending forces. Moreover, due to their hollow cross-section, they are lightweight yet maintain high strength. This makes them a cost-effective solution for various projects.

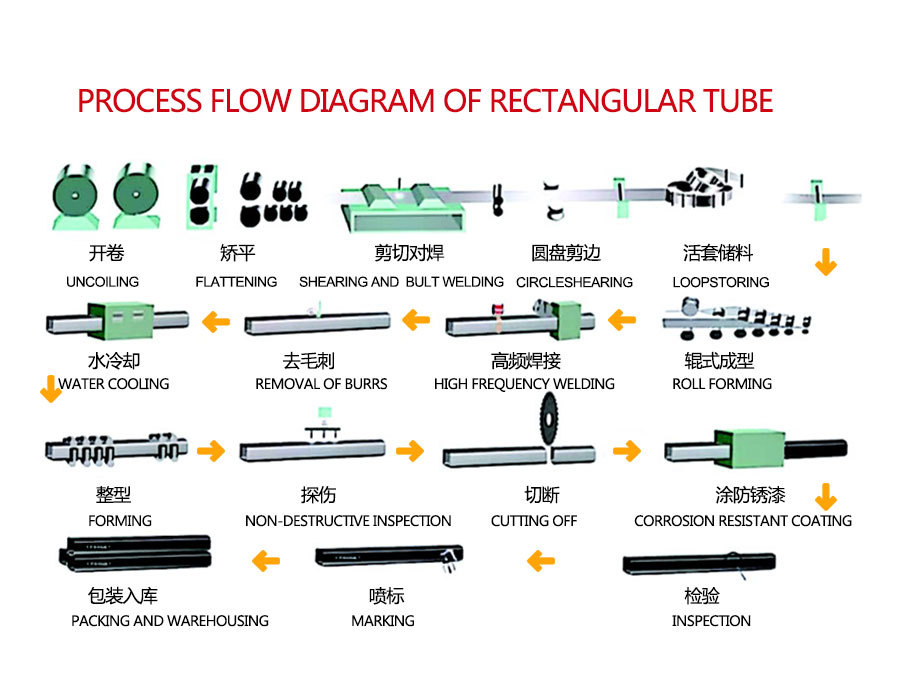

V. Manufacturing process of 2 x 5 rectangular tubes

VI. Quality standards and certifications

Standards: ASTM A500/A501,EN10219/10210,JIS G3466,GB/T6728/3094 AS1163, CSA G40.20/G40.21

Certifications: CE,LEED,BV,PHD&EPD,BC1,EN 10210,EN10219,ISO9000,ASTM A500,ASTM A501,AS1163,JIS G3466,DNV,ABS,SGS,CNAS,etc

VII. Common variations of 2 x 5 rectangular tubes

Apart from the standard dimensions, variations of 2 x 5 rectangular tubes are available to meet diverse project requirements. This includes hollow sections, different thicknesses, and even customizations based on specific design needs. The versatility of these tubes expands their usage in various industries.

VIII. Maintenance and care of 2 x 5 rectangular tubes

Proper maintenance and care of 2 x 5 rectangular tubes are essential to ensure their longevity and performance. Regular cleaning, corrosion prevention measures, and periodic inspections are necessary to identify and address any potential issues promptly. Adhering to maintenance guidelines will help extend the lifespan of these structural components.

IX. Comparison with other tube types

When considering structural components, it is crucial to compare 2 x 5 rectangular tubes with other types of tubes available in the market. Unlike square tubes or round tubes, rectangular tubes offer a unique shape that allows for efficient space utilization. Each tube type has its own advantages and specific applications, making it essential to choose the right one for a particular project.

X. Future developments and trends

The realm of structural components is continuously evolving, and 2 x 5 rectangular tubes are no exception. Ongoing research and advancements in technology aim to further improve the quality, durability, and design capabilities of these tubes. With the constant pursuit of innovation, the future holds even more possibilities for the utilization of 2 x 5 rectangular tubes in various sectors.

XI. Conclusion

In conclusion, 2 x 5 rectangular tubes provide a versatile and efficient solution for various industries and applications. Their unique shape, combined with their strength and cost-effectiveness, makes them a preferred choice for structural components. The proper maintenance and adherence to quality standards ensure their longevity and reliability in diverse projects.

FAQs

What are the weight and load-bearing capacity of a 2 x 5 rectangular tube?

The weight and load-bearing capacity of a 2 x 5 rectangular tube depend on the material used and the wall thickness. It is recommended to consult the manufacturer or refer to engineering specifications to determine the exact weight capacity.

Can 2 x 5 rectangular tubes be used in outdoor applications?

Yes, 2 x 5 rectangular tubes can be used in outdoor applications. However, it is essential to consider the environmental conditions and choose a material with appropriate corrosion resistance properties to ensure their durability.

Are there any limitations to using 2 x 5 rectangular tubes in construction projects?

While 2 x 5 rectangular tubes offer many advantages, there may be limitations in terms of structural design and compatibility with certain construction methods. It is advisable to consult with structural engineers to ensure the suitability of these tubes for specific construction projects.

Can 2 x 5 rectangular tubes be cut and welded easily?

Yes, 2 x 5 rectangular tubes can be easily cut and welded using appropriate tools and techniques. However, it is recommended to follow safety guidelines and consult professionals to ensure precise and secure welding joints.

Where can I purchase 2 x 5 rectangular tubes?

2 x 5 rectangular tubes can be purchased from various suppliers and distributors offering metal or construction materials. Local steel or metal fabrication companies, hardware stores, or online marketplaces are good sources to explore for purchasing these tubes.