YuanTai DeRun–Hot Dipped Galvanized Steel

- Share

- Issue Time

- Jul 21,2025

Summary

Hot-dip galvanized steel is an integral part of modern construction projects and is the primary material for steel structures that require corrosion protection.

YuanTai DeRun–Hot Dipped Galvanized Steel

Hot-dip galvanized pipes, in order to improve the corrosion resistance of steel pipes, general steel pipes are galvanized. Galvanized steel pipes are divided into hot-dip galvanizing and electro-galvanizing. Hot-dip galvanizing has a thick galvanized layer, electro-galvanizing has a low cost, and the surface is not very smooth.

Galvanized steel pipes are divided into cold-dip galvanized pipes and hot-dip galvanized pipes.

Hot-dip galvanized pipes are to make molten metal react with the iron matrix to produce an alloy layer, so that the matrix and the coating are combined. Hot-dip galvanizing is to pickle the steel pipe first. In order to remove the iron oxide on the surface of the steel pipe, after pickling, it is cleaned in an ammonium chloride or zinc chloride aqueous solution or a mixed aqueous solution of ammonium chloride and zinc chloride, and then sent to the hot-dip plating tank. Hot-dip galvanizing has the advantages of uniform coating, strong adhesion, and long service life. The steel pipe matrix undergoes complex physical and chemical reactions with the molten plating solution to form a corrosion-resistant zinc-iron alloy layer with a tight structure. The alloy layer is integrated with the pure zinc layer and the steel pipe matrix. Therefore, it has strong corrosion resistance.

Hot-dip galvanized steel pipes are widely used in the fields of construction and engineering, and their material grade directly affects the quality and service life of the product. Choosing the right material grade is crucial to the safety and reliability of the project. The following will introduce the material grades and characteristics of hot-dip galvanized steel pipes to help you better understand and purchase suitable products.

1. Material grade classification:

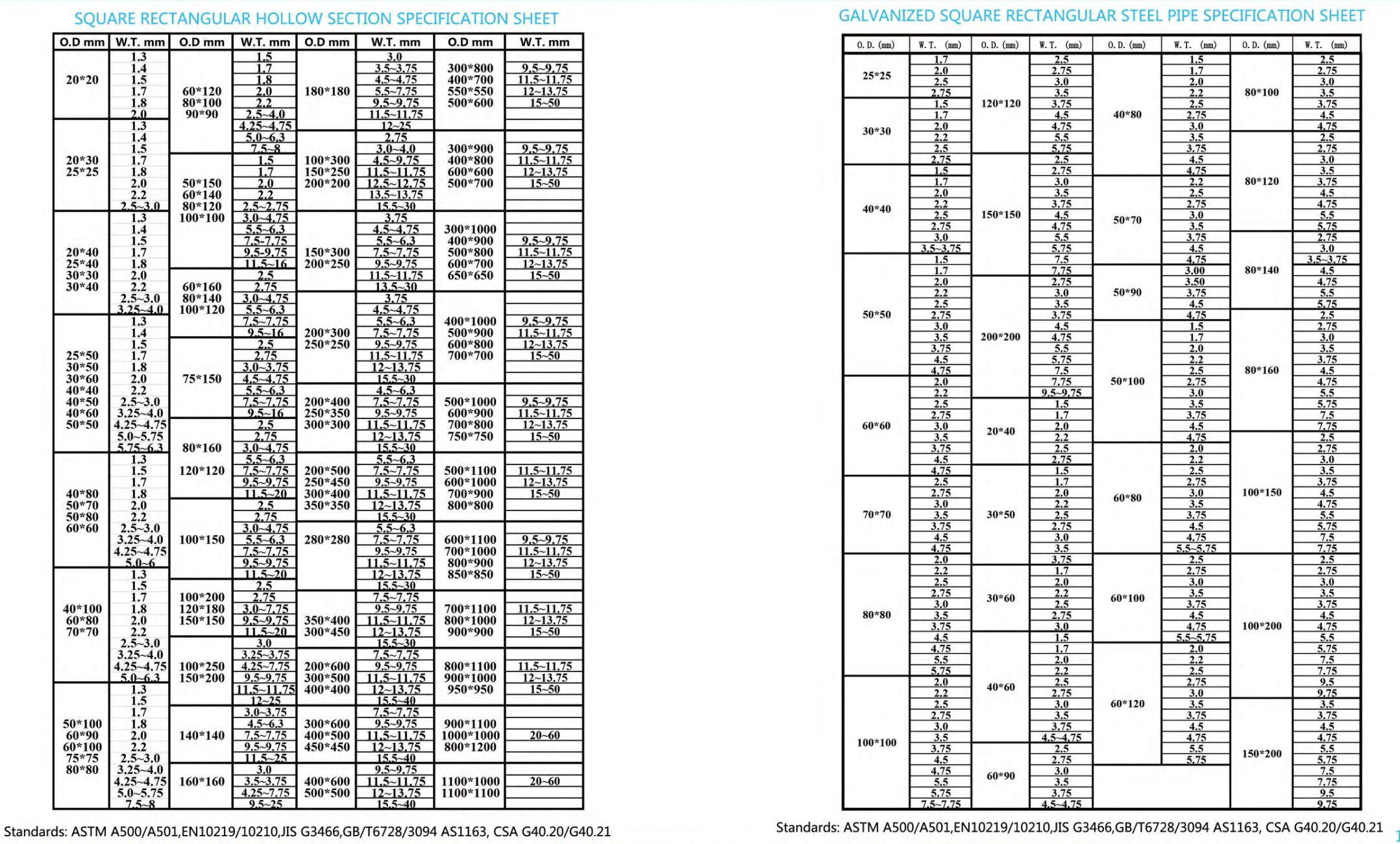

The material grades of hot-dip galvanized steel pipes are usually classified according to international standards. Common grades include Q195, Q235, and Q345, among which Q235 and Q345 are more commonly selected grades. These grades represent indicators of the material composition and mechanical properties of the steel pipes, and different grades are suitable for different engineering needs.

2.Q195:

-Q195 steel pipes are low-carbon steel with good formability and weldability. They are often used in general low-pressure fluid transportation, structural support and other occasions.

-Suitable for some occasions where the material requirements are not particularly high, and the price is relatively economical.

3.Q235:

-Q235 steel pipe is a common carbon structural steel with good mechanical properties and weldability. It is widely used in building structures, bridges, pipelines and other fields.

-It is suitable for projects with high material strength requirements and is a common selection grade.

4.Q345:

-Q345 steel pipe is a high-strength low-alloy structural steel with high strength and corrosion resistance. It is often used in engineering projects that bear large loads or harsh environments.

-It is suitable for engineering projects that need to bear heavy loads and have high corrosion resistance requirements. The quality and safety performance are more reliable.