Custom Steel Pipe

- Share

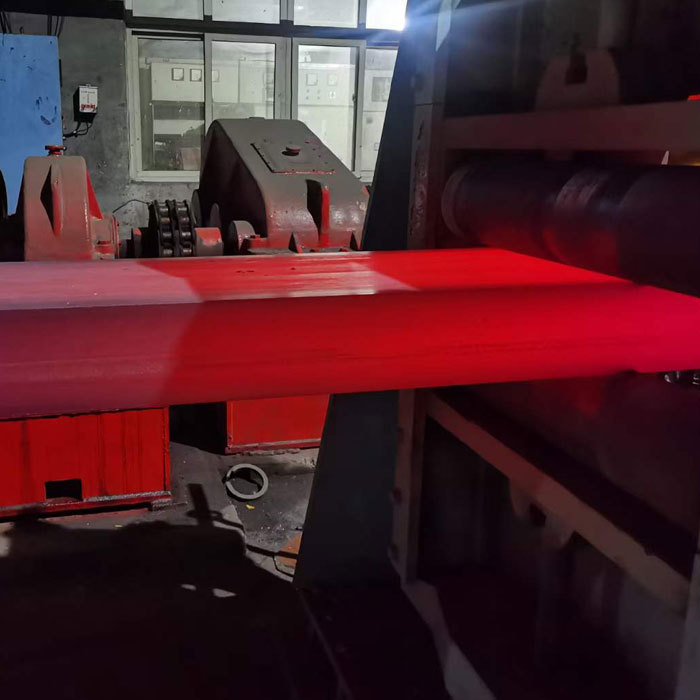

After 21 years of long-term focus on steel pipe manufacturing, Yuantai Derun Steel Pipe Manufacturing Group has evolved its ability to customize steel pipes.

Why do I say that? Because the demands of customers in the market are always ever-changing. Different steel pipe purchasers also have different requirements for steel pipes. When you find that your steel pipes require different thicknesses, lengths, and materials, and the applicable scenarios require more specific performance indicators, you need a reliable and reliable steel pipe customization manufacturer. After tens of thousands of steel pipe production trials, Yuantai Derun has been able to meet the requirements of customized steel pipes for customers. Mainly manifested in these aspects.

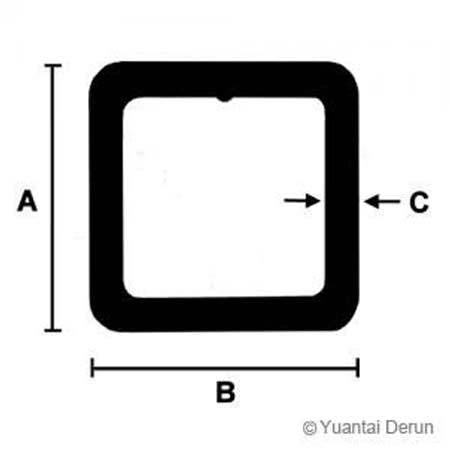

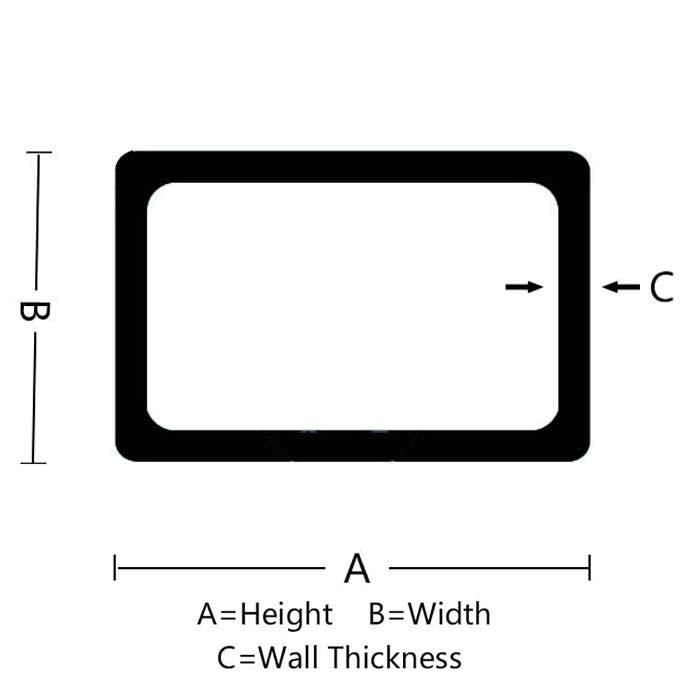

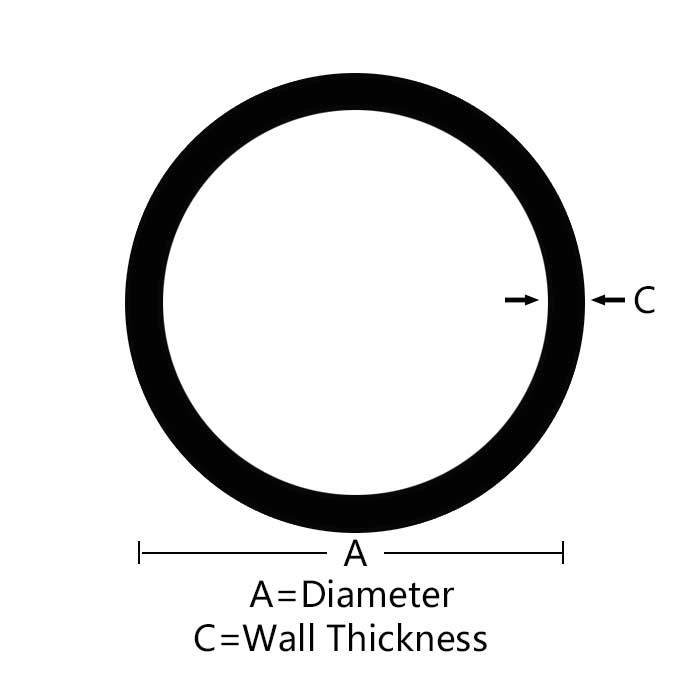

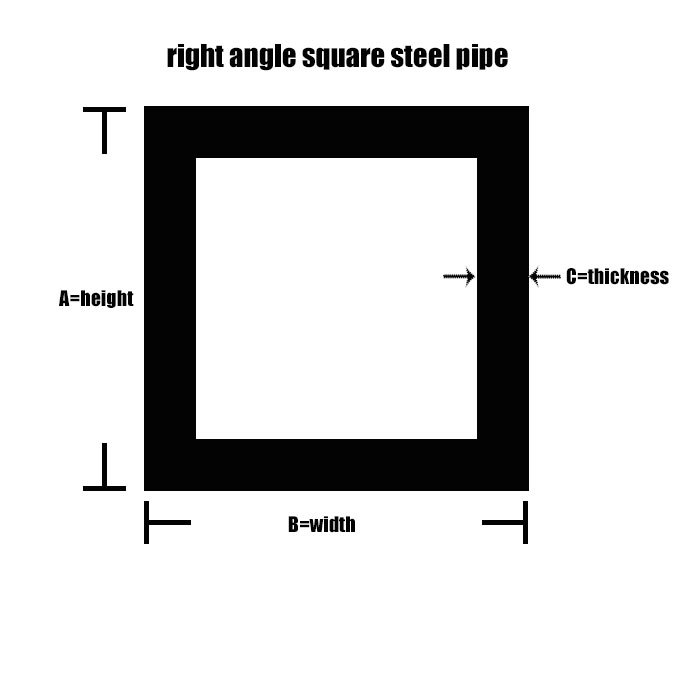

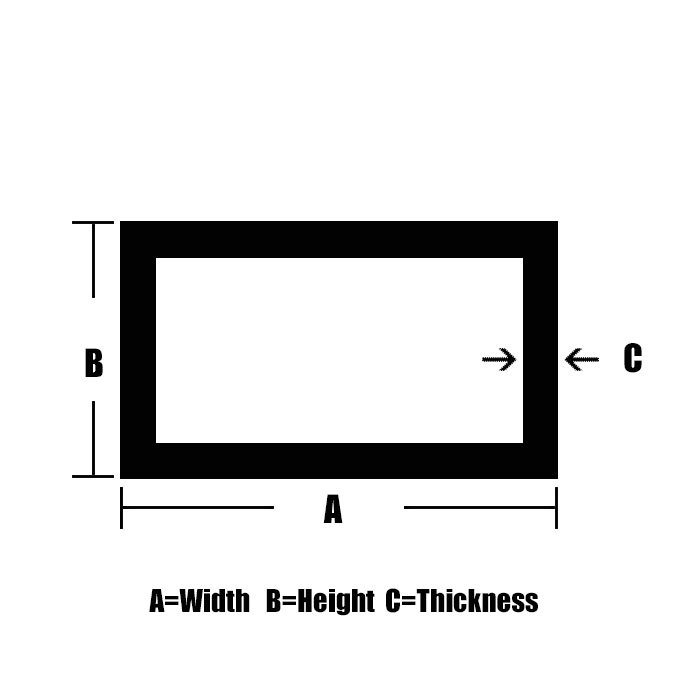

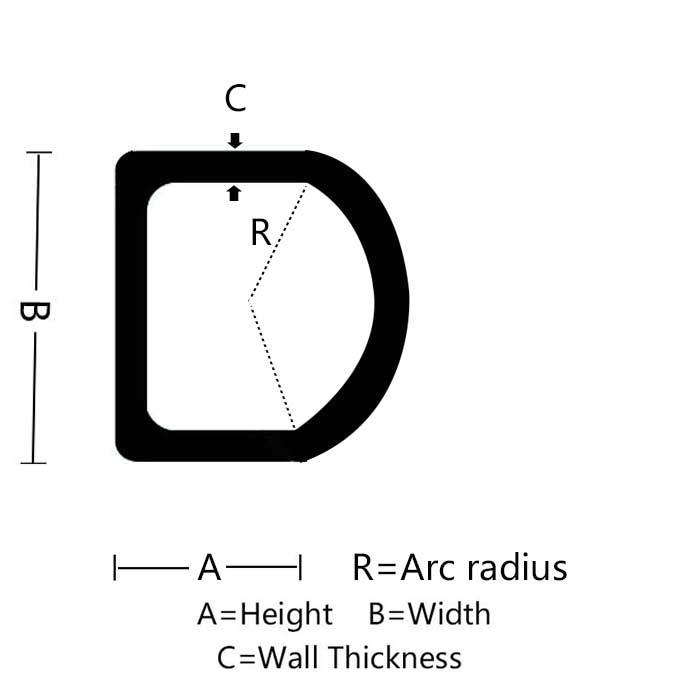

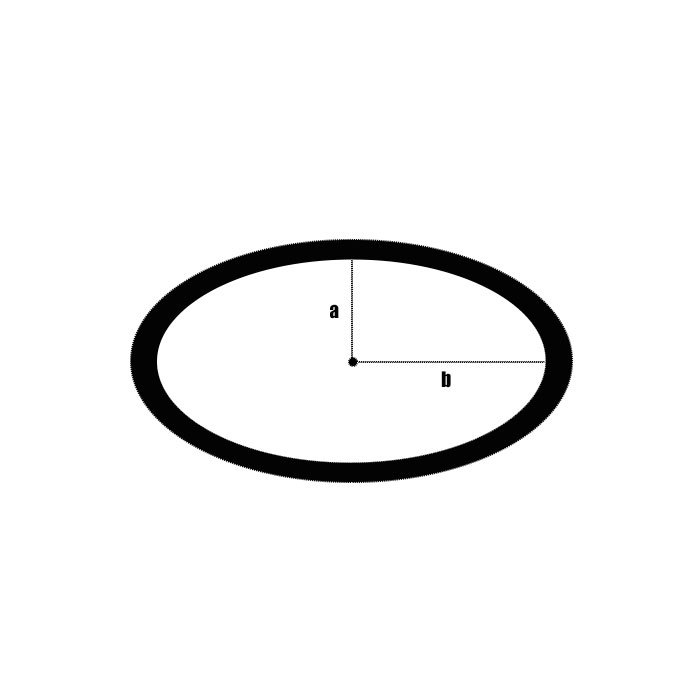

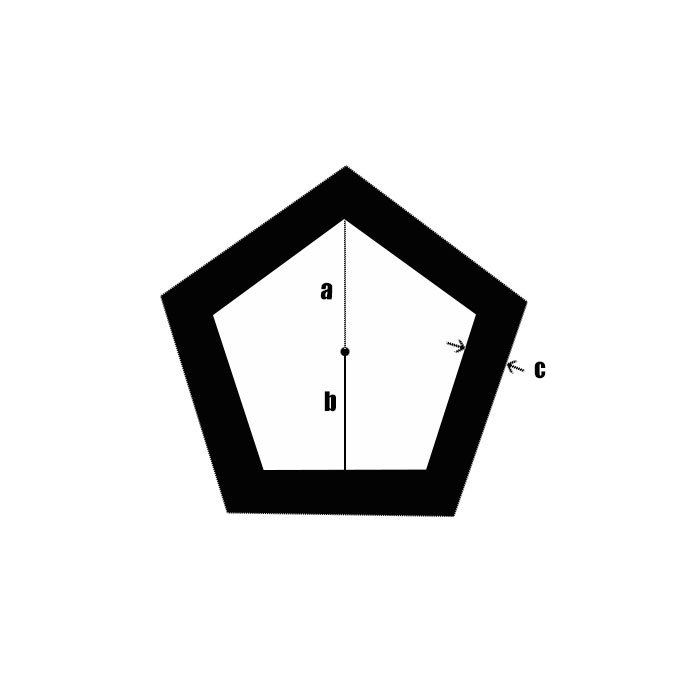

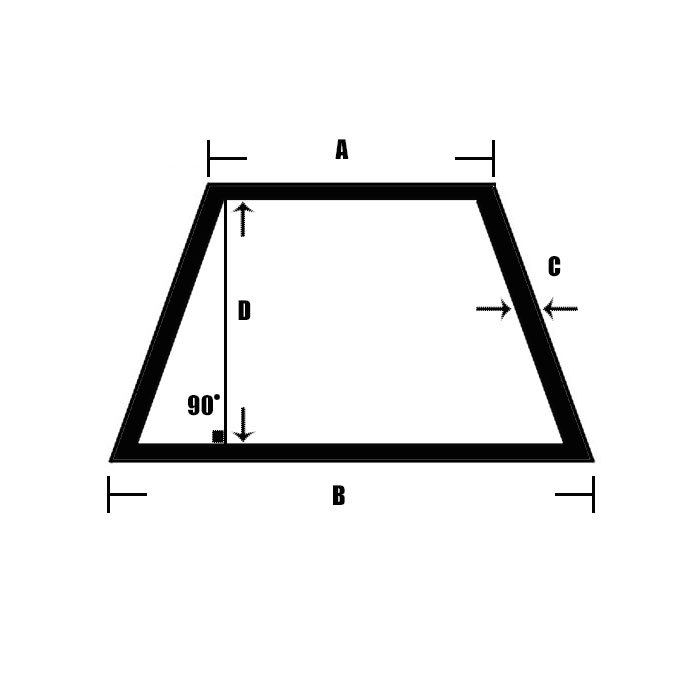

1. Customization Of Steel Pipe Shape

Whether you need square steel pipes, rectangular steel pipes, circular steel pipes, triangular steel pipes, diamond shaped steel pipes, trapezoidal steel pipes, D-shaped steel pipes, or any irregular shaped steel pipe. We can all customize it for you. The following are some shapes of steel pipes that we have customized before.

2. Customized Steel Pipe Diameter

Structural steel pipes have different diameters due to their different application fields. But regardless of the diameter of the steel pipe you need, Yuantai Derun can customize it for you. Of course, what are the minimum and maximum diameter structural steel pipes? Let's take you through it.

Small diameter square rectangular tube

The minimum diameter square tube of Yuantai Derun can reach 10mm × 10mm

Large diameter square rectangular tube

The maximum diameter square tube of Yuantai Derun can reach 1200mm × 1200mm & 800×1200mm

Square rectangular tube wall thickness can be customized

The wall thickness of Yuantai Derun square rectangular tube can generally range from 0.5mm to 60mm

3. Customized Steel Pipe Length

Steel pipe sellers can customize the length at Yuantai Derun Steel Pipe Manufacturing Group. Generally, the common steel pipe lengths are 3 meters, 6 meters, 9 meters, and 12 meters. You can also customize the length of your own steel pipe, from 0.5 to 24 meters, and we can cut and process the steel pipe.

4. Customized Steel Pipe Processing

1.) Surface treatment method for steel pipes

Hot dip galvanizing treatment, oil coating treatment, spray painting treatment, sandblasting treatment, shot blasting treatment, 3PE anti-corrosion treatment, etc

2.) Steel pipe port processing method

Groove treatment, threading treatment, expanding treatment, reducing treatment, punching treatment, polishing treatment, etc.

3.) Steel pipe stress relief treatment

Natural treatment, four corner heating treatment, steel pipe heating treatment, etc.

5.Material Customization

Customers can customize materials according to their own usage scenarios. You can choose carbon steel, alloy steel, or stainless steel. Yuantai Derun Steel Pipe Manufacturing Group can process different materials according to the specific usage of customers. Warmly welcome global buyers to inquire and place orders.

Steel Grade:S235/275/325/355/420/460,Gr.A/B/C/D,STKR 400/490,SS400,16Mn,45cr,40cr,Q195/235/345/355,C250/350/450,S304/314/316,etc.

Of course, if you are not sure about the quality of our products, you can conduct free steel pipe sample testing before ordering steel pipes. If it is qualified, you are also very welcome to cooperate with us to place an order. In short, for the buyer of steel tubes, choose Yuantai. Free you from all your worries.