EN10219 S460NH square hollow section sizes 10×10-1000×1000mm

- Model

- S460NH

Item specifics

- Thickness

- 0.5- 60 mm

- OD(Outer diameter)

- 10*10-1200*1200mm

- Certification

- CE,LEED,BV,PHD&EPD,BC1,EN 10210,EN10219,ISO9000

- Surface Treatment

- Black painted or REQUEST

- Tolerance

- as required

- Length

- 0.5-26.5M according to client requirement

- Materials

- S460NH

- Delivery Time

- 7-30 Days

Review

Description

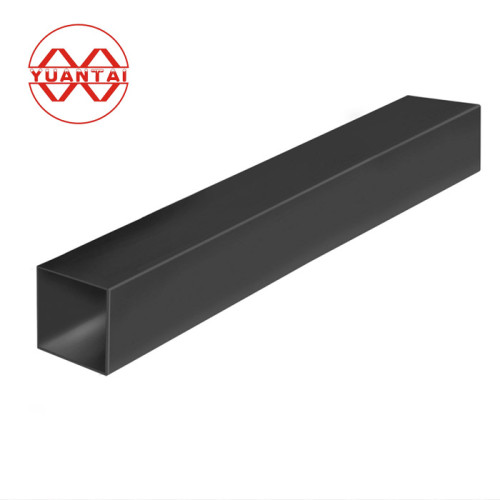

EN10219 S460NH Square Hollow Section Sizes 10×10-1000×1000mm

Square hollow sections (SHS) have gained immense popularity in modern construction due to their versatility and strength. Among the various options available, the EN10219 S460NH square hollow section stands out as a superior choice.S460NH square hollow section produced by Yuantai Derun is a top pick due to its unique properties and strong structural characteristics.

Advantages Of EN10219 S460NH Square Hollow Section

EN10219 S460NH square hollow section offers several advantages that make it a preferred choice for construction purposes. Its main benefits include:

High strength: EN10219 S460NH square hollow section provides exceptional strength, making it suitable for structures requiring load-bearing capabilities.

Durability: The material's resistance to corrosion and environmental factors ensures long-term durability.

Versatility: EN10219 S460NH square hollow section can be easily modified, cut, and welded to meet specific project requirements.

Cost-effectiveness: Opting for EN10219 S460NH square hollow sections can result in reduced construction costs without compromising on quality or safety.

More Types Of EN10219 S460NH Square Steel Tube For You

Yuantai Derun is the Leading Square Steel Tube Manufacturers in China. We mainly produce these types of EN10219 S460NH square metal tubes. Send the required type immediately!

Black Mild Steel Welded EN10219 S460NH Square Metal Tube Fitting

Hot Dipped Galvanized EN10219 S460NH Square Steel Tube

Right Angle Welding EN10219 S460NH Square Steel Tubing

Carbon Steel Seamless EN10219 S460NH Square Hollow Section

Complete EN10219 S460NH Square Hollow Section Sizes For You

At Yuantai Derun, you can order any specification of EN10219 S460NH square hollow section. The specific product specifications are as follows, please contact us immediately!

|

En10219 S460nh Square Metal Tube Sizes

|

|||

|

Type

|

Outer Diameter(mm)

|

Wall Thickness(mm)

|

Length(M)

|

|

Welded Square Tube

|

10×10-1200×1200

|

0.5-60

|

0.5-26.5

|

|

Seamless Square Tube

|

10×10-800×800

|

0.5-100

|

0.5-24

|

Hot Dipped Galvanised Square Tube | 20×20-1200×1200 | 1-60 | 0.5-26.5 |

Flexibly Customize Your EN10219 S460NH Square Steel Tube Fitting

At Yuantai Derun, you can flexibly customize your EN10219 S460NH square fittings. The following are customization options:

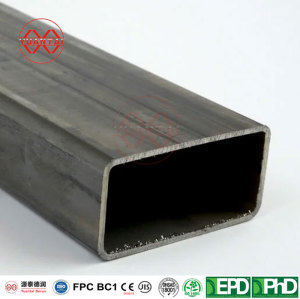

1. Shape customization

You can flexibly customize the shape of EN10219 S460NH square tube. Common shapes include rounded square tube and right angle square tube.

2. Surface treatment

You can flexibly customize the surface treatment method of EN10219 S460NH square steel pipes to better protect the pipes from external corrosion. Common surface treatment methods include oil coating, spray painting, hot-dip galvanizing, and so on.

3. Processing

You can flexibly choose the processing method of EN10219 S460NH square tube at Yuantaide Run, such as punching, cutting, welding, bending and other services, to save customers' processing costs. Send Your Inquiry Now!

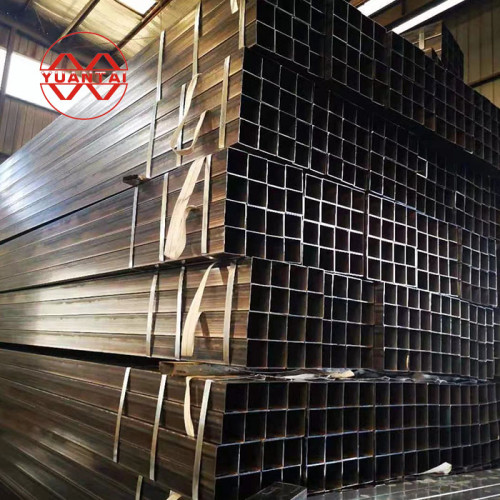

Large EN10219 S460NH Square Metal Tube Stock For You

Yuantai Derun has the largest spot inventory of EN10219 S460NH square metal pipes in China, with approximately 200000 tons of structural steel pipes in stock to meet your urgent order needs. Inquire immediately.

Free EN10219 S460NH Square Hollow Section Samples For You

In order to enable users to quickly understand the quality of EN1219 S460NH square hollow sections produced by Yuantaide Run, a free sample policy has been launched. This allows buyers who have strict quality requirements for square hollow sections in important projects to quickly understand the capabilities of a square tube manufacturer. The sample length requirement is within 20 centimeters, and buyers only need to pay a small shipping fee to obtain free samples immediately!

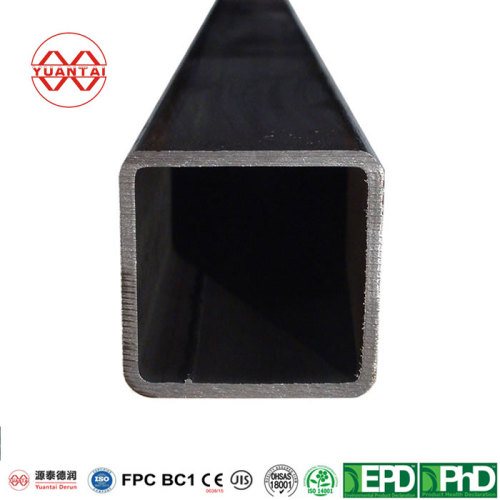

Strict EN10219 S460NH Square Hollow Section Testing

At Yuantai Derun, we will strictly conduct various tests on EN10219 S460NH square hollow sections according to customer requirements, and can display them online to every global purchaser. Common square tube testing items include: appearance inspection, caliber, wall thickness, straightness, chemical composition testing, yield strength testing, tensile strength testing, impact testing, hardness testing, X-ray testing, ultrasonic testing, salt spray testing, etc. Send your request immediately!

Authoritative Organization Certification

The square hollow section produced by Yuantai Derun has not only passed the European EN10219 certification, but also passed authoritative certifications such as ISO9001, EN10210, BC1, EPD, PHD, BV, DNV, ABS, API 5L, etc. These qualifications can assist purchasers in participating in local project bidding, greatly facilitating their participation.

Strong Production Capacity Of S460NH Square Hollow Section

At Yuantai Derun, we have over 70 square hollow section production lines with a saturated annual production capacity of up to 10 million tons, which can meet your needs for fast delivery.

EN10219 S460NH Square Hollow Section Chemical Composition

Carbon ≤ 0.20%, silicon ≤ 0.60%, manganese ≤ 1.0-1.70%, phosphorus ≤ 0.035%, sulfur ≤ 0.030%, niobium ≤ 0.05%, vanadium ≤ 0.20%,

Aluminum ≥ 0.020%, titanium ≤ 0.03%, chromium ≤ 0.30%, nickel ≤ 0.8%, molybdenum ≤ 0.10%, copper ≤ 0.35%, nitrogen ≤ 0.025%,

EN10219 S460NH Square Steel Hollow Section Mechanical Properties

Wall thickness ≤ 16mm: yield strength ≥ 460MPa, tensile strength ≥ 550-720MPa, elongation ≥ 17%

16mm<wall thickness ≤ 40mm: yield strength ≥ 440MPa, tensile strength ≥ 550-720MPa, elongation ≥ 17%

Application Of EN10219 S460NH Square Hollow Section

1. Structural engineering: widely used in the construction of buildings, bridges, and towers, where high strength and durability are crucial.

2. Manufacturing and industrial applications: Engaged in the manufacturing of components and structures in manufacturing plants, warehouses, and other industrial facilities.

3. Mechanical engineering: Due to its strength to weight ratio, it is common in the production of frames, chassis, and brackets for machines and equipment.

4. Transportation infrastructure: used for railways and transportation structures, including railway platforms and vehicle support frames.

5. Offshore and marine applications: Suitable for structures exposed to harsh environmental conditions, such as offshore platforms and marine equipment.

6. Agriculture: Due to its durability and resistance to environmental factors, it is commonly used for agricultural equipment frames and structures.

7. Steel structure: It plays a crucial role in steel structure systems and modular buildings, with high strength and minimal weight being beneficial.

8. Architectural applications: Used for building structures and aesthetic applications where both strength and visual appeal are important.

FAQS

Q1: Can S460NH square hollow section be used in outdoor applications exposed to weather conditions?

There are two types of square hollow sections, a black square hollow section that is not directly exposed to the outdoor environment. One is a hot-dip galvanized square hollow section, which is ready to be exposed to the outdoor environment.

Q2: What are the common shapes available in square hollow sections?

Right-angled square hollow section, rounded angle square hollow section

Q3: Can square metal tube fittings be welded?

Yes,of course.

Q4: Are there any limitations on the length of square metal tubes available in the market?

Yes,0.5-26.5M

Q5: How does S460NH square hollow section contribute to sustainable construction practices?

It can withstand high pressure and weight, making it ideal for use in the construction of large buildings.