EN10219 S275JRH SHS Mild Steel Pipe | Customizable Solutions by China's Largest Manufacturer

- Model

- hfw-yt-S275JRH

Item specifics

- Thickness

- 0.5- 60 mm

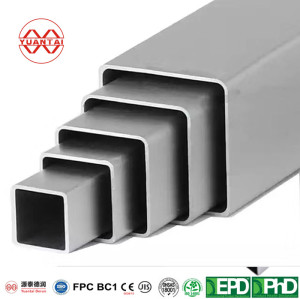

- OD(Outer diameter)

- 10*10-1000*1000mm

- Certification

- CE,LEED,BV,PHD&EPD,BC1,EN 10210,EN10219,ISO9000

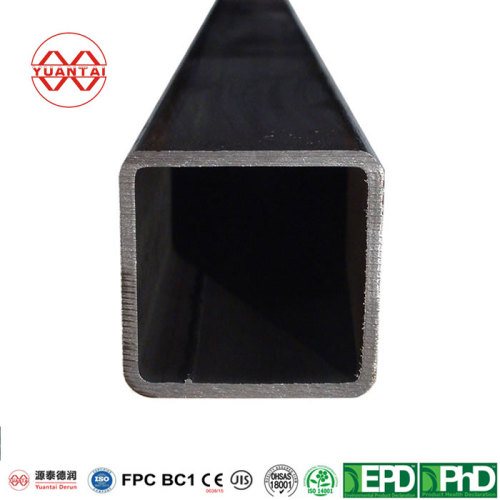

- Surface Treatment

- Black painted or REQUEST

- Tolerance

- as required

- Length

- 0.5-24M according to client requirement

- Standards

- Hollow section: ASTM A500/A501,EN10219,EN10210

- Materials

- S275JRH

- Delivery Time

- 7-30 Days

Review

Description

O.D. mm | W.T.mm | O.D mm | W.T. mm | O.D mm | W.T. mm | O.D mm | W.T. mm |

20*20 | 1.3 | 60*120 80*100 90*90 | 1.50 | 180*180 | 3 | 300*800 400*700 550*550 500*600 | |

1.4 | 1.70 | 3.5-3.75 | 9.5-9.75 | ||||

1.5 | 1.80 | 4.5-4.75 | 11.5-11.75 | ||||

1.7 | 2.00 | 5.5-7.75 | 12-13.75 | ||||

1.8 | 2.20 | 9.5-9.75 | 15-50 | ||||

2.0 | 2.5-4.0 | 11.5-11.75 | | ||||

20*30 25*25 | 1.3 | 4.25-4.75 | 12.0-25.0 | | |||

1.4 | 5.0-6.3 | 100*300 150*250 200*200 | 2.75 | 300*900 400*800 600*600 500*700 | | ||

1.5 | 7.5-8 | 3.0-4.0 | 9.5-9.75 | ||||

1.7 | 50*150 60*140 80*120 100*100 | 1.50 | 4.5-9.75 | 11.5-11.75 | |||

1.8 | 1.70 | 11.5-11.75 | 12-13.75 | ||||

2.0 | 2.00 | 12.5-12.75 | 15-50 | ||||

2.2 | 2.20 | 13.5-13.75 | | ||||

2.5-3.0 | 2.5-2.75 | 15.5-30 | | ||||

20*40 25*40 30*30 30*40 | 1.3 | 3.0-4.75 | 150*300 200*250 | 3.75 | 300*1000 400*900 500*800 600*700 650*650 | | |

1.4 | 5.5-6.3 | 4.5-4.75 | | ||||

1.5 | 7.5-7.75 | 5.5-6.3 | 9.5-9.75 | ||||

1.7 | 9.5-9.75 | 7.5-7.75 | 11.5-11.75 | ||||

1.8 | 11.5-16 | 9.5-9.75 | 12-13.75 | ||||

2.0 | 60*160 80*140 100*120 | 2.50 | 11.5-11.75 | 15-50 | |||

2.2 | 2.75 | 13.5-30 | | ||||

2.5-3.0 | 3.0-4.75 | 200*300 250*250 | 3.75 | 400*1000 500*900 600*800 700*700 | | ||

3.25-4.0 | 5.5-6.3 | 4.5-4.75 | | ||||

25*50 30*50 30*60 40*40 40*50 40*60 50*50 | 1.3 | 7.5-7.75 | 5.5-6.3 | 9.5-9.75 | |||

1.4 | 9.5-16 | 7.5-7.75 | 11.5-11.75 | ||||

1.5 | 75*150 | 2.50 | 9.5-9.75 | 12-13.75 | |||

1.7 | 2.75 | 11.5-11.75 | 15-50 | ||||

1.8 | 3.0-3.75 | 12-13.75 | | ||||

2.0 | 4.5-4.75 | 15.5-30 | | ||||

2.2 | 5.5-6.3 | 200*400 250*350 300*300 | 4.5-6.3 | 500*1000 600*900 700*800 750*750 | | ||

2.5-3.0 | 7.5-7.75 | 7.5-7.75 | 9.5-9.75 | ||||

3.25-4.0 | 9.5-16 | 9.5-9.75 | 11.5-11.75 | ||||

4.25-4.75 | 80*160 120*120 | 2.50 | 11.5-11.75 | 12-13.75 | |||

5.0-5.75 | 2.75 | 12-13.75 | 15-50 | ||||

5.75-6.3 | 3.0-4.75 | 15.5-30 | | ||||

40*80 50*70 50*80 60*60 | 1.3 | 5.5-6.3 | 200*500 250*450 300*400 350*350 | 5.5-6.3 | 500*1100 600*900 700*800 800*800 | | |

1.5 | 7.5-7.75 | 7.5-7.75 | 9.5-9.75 | ||||

1.7 | 9.5-9.75 | 9.5-9.75 | 11.5-11.75 | ||||

1.8 | 11.5-20 | 11.5-11.75 | 12-13.75 | ||||

2.0 | 100*150 | 2.50 | 12-13.75 | 15-50 | |||

2.2 | 2.75 | 15.5-30 | | ||||

2.5-3.0 | 3.0-4.75 | 280*280 | 5.5-6.3 | 600*1100 700*1000 800*900 850*850 | | ||

3.25-4.0 | 5.5-6.3 | 7.5-7.75 | 9.5-9.75 | ||||

4.25-4.75 | 7.5-7.75 | 9.5-9.75 | 11.5-11.75 | ||||

5.0-6.0 | 9.5-9.75 | 11.5-11.75 | 12-13.75 | ||||

40*100 60*80 70*70 | 1.3 | 11.5-20 | 12-13.75 | 15-50 | |||

1.5 | 100*200 120*180 150*150 | 2.50 | 15.5-30 | | |||

1.7 | 2.75 | 350*400 300*450 | 7.5-7.75 | 700*1100 800*1000 900*900 | | ||

1.8 | 3.0-7.75 | 9.5-9.75 | 11.5-11.75 | ||||

2.0 | 9.5-9.75 | 11.5-11.75 | 12-13.75 | ||||

2.2 | 11.5-20 | 12-13.75 | 15-50 | ||||

2.5-3.0 | 100*250 150*200 | 3.00 | 15.5-30 | | |||

3.25-4.0 | 3.25-3.75 | 200*600 300*500 400*400 | 7.5-7.75 | 800*1100 900*1000 950*950 | | ||

4.25-4.75 | 4.25-4.75 | 9.5-9.75 | 11.5-11.75 | ||||

5.0-6.3 | 9.5-9.75 | 11.5-11.75 | 12-13.75 | ||||

50*100 60*90 60*100 75*75 80*80 | 1.3 | 11.5-11.75 | 12-13.75 | 15-50 | |||

1.5 | 12.25 | 15.5-40 | | ||||

1.7 | 140*140 | 3.0-3.75 | 300*600 400*500 450*450 | 7.5-7.75 | 900*1100 1000*1000 800*1200 | | |

1.8 | 4.5-6.3 | 9.5-9.75 | | ||||

2.0 | 7.5-7.75 | 11.5-11.75 | 20-60 | ||||

2.2 | 9.5-9.75 | 12-13.75 | | ||||

2.5-3.0 | 11.5-25 | 15.5-40 | | ||||

3.25-4.0 | 160*160 | 3.00 | 400*600 500*500 | 9.5-9.75 | 1100*1000 1200*1200 | | |

4.25-4.75 | | 3.5-3.75 | 11.5-11.75 | 20-60 | |||

5.0-5.75 | | 4.25-7.75 | 12-13.75 | | |||

7.5-8 | | 9.5-25 | 15.5-40 | |