Versatile EN10219 S355NH 1/2 Square Tube Hollow Steel Pipe

- Model

- S355NH

Item specifics

- Thickness

- 0.5- 2.75 mm

- OD(Outer diameter)

- 1/2 inch

- Certification

- CE,LEED,BV,PHD&EPD,BC1,EN 10210,EN10219,ISO9000

- Surface Treatment

- Black painted or REQUEST

- Tolerance

- as required

- Length

- 0.5-26.5M according to client requirement

- Materials

- S355NH

- Delivery Time

- 7-30 Days

Review

Description

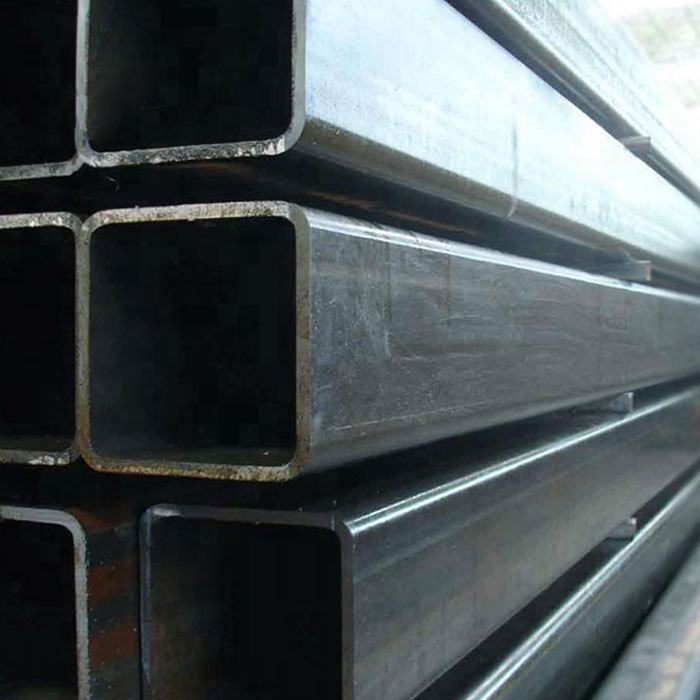

EN10219 S355NH 1/2 Square Tube Steel

EN10219 S355NH 1/2 Square Tube Steel is a type of structural hollow sections of fine grain steels, It is produced strictly in accordance with the European standard EN10219 and uses S355NH grade raw materials. EN10219 S355NH 1/2 Square Tube Steel has good load-bearing performance, welding performance, and excellent toughness, making it a very environmentally friendly green building material. EN10219 S355NH 1/2 Square Tube Steel is widely used in construction, bridges, and other structural applications. EN10219 S355NH 1/2 Square Tube Steel is a material with high requirements for structural components.Send the request immediately.

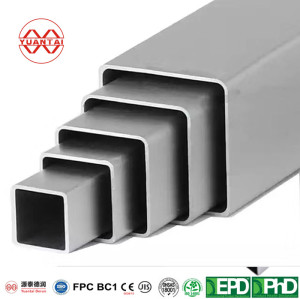

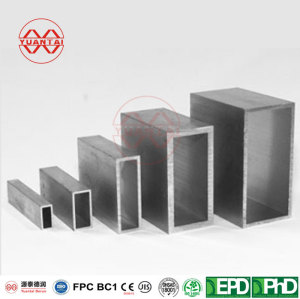

Hot Selling Types Of Square Steel Tube 1/2 Inch

The following are four popular Square Steel Tube 1/2 Inch products from Yuantai Derun, with varying degrees of corrosion resistance: black high-frequency welded Square Steel Tube 1/2 Inch, pre galvanized Square Steel Tube 1/2 Inch, zinc aluminum magnesium coated Square Steel Tube 1/2 Inch, and hot-dip galvanized Square Steel Tube 1/2 Inch.

Black High-Frequency Welded Square Steel Tube 1/2 Inch

Pre Galvanized Square Steel Tube 1/2 Inch

Zinc Aluminum Magnesium Coated Square Steel Tube 1/2 Inch

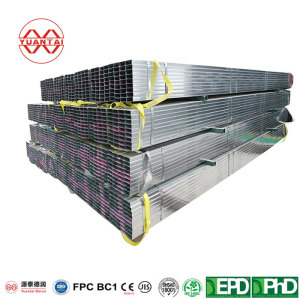

Hot-Dip Galvanized Square Steel Tube 1/2 Inch

Chemical Composition

Carbon ≤ 0.20%, silicon ≤ 0.50%, manganese ≤ 0.9-1.65%, phosphorus ≤ 0.035%, sulfur ≤ 0.030%, niobium ≤ 0.05%, vanadium ≤ 0.12%,

Aluminum ≥ 0.020%, titanium ≤ 0.03%, chromium ≤ 0.30%, nickel ≤ 0.5%, molybdenum ≤ 0.10%, copper ≤ 0.35%, nitrogen ≤ 0.015%

Mechanical Properties

Wall thickness ≤ 16mm: yield strength ≥ 355MPa, tensile strength ≥ 470-630MPa, elongation ≥ 22%

16mm < wall thickness ≤ 40mm: yield strength ≥ 345MPa, tensile strength ≥ 470-630MPa, elongation ≥ 22%

S355NH Hollow Section Coating

At Yuantai Derun,There are 4 types of coating for your S355NH Hollow Sections.

1.oiling

2.painted

3.hot dipped galvanizing

4.other coating type

Benefits Of EN10219 S355NH Square Steel Tube

The advantages of EN10219 S355NH Square Steel Tube are mainly reflected in the following aspects:

High strength: S355NH material has high yield strength and tensile strength, suitable for withstanding large loads, and is widely used in construction and structural engineering.

Good weldability: This material has excellent weldability and is suitable for various welding processes, making it more convenient for construction.

Corrosion resistance: The treated S355NH square tube has a certain degree of corrosion resistance and is suitable for use in harsh environments.

Wide applicability: It can be used in multiple fields such as bridges, buildings, and mechanical manufacturing to meet different engineering needs.

Free EN10219 S355NH 1/2 Square Tube Steel Sample For You

In order to quickly inform customers about the product quality of EN10219 S355NH 1/2 Square Tube Steel, Yuantai Derun has launched a free sample policy. The sample length needs to be within 20 centimeters, and you only need to pay one shipping fee. Get free samples immediately.

Other Value-Added Services

For EN10219 S355NH 1/2 Square Tube Steel, Yuantai Derun can also provide you with some other value-added services, such as heat treatment, corner heating, polishing, welding, cutting, punching, and so on. Please consult the account manager for specific details.

Packaging And Shipping

For the packaging of EN10219 S355NH 1/2 Square Tube Steel, Yuantai Derun strictly follows the relevant international standards for packaging, and the number of packaged pieces is also executed according to the corresponding regulations. If you have any other questions, you can consult the account manager.

For the transportation of EN10219 S355NH 1/2 Square Tube Steel, container sea freight or bulk cargo is generally used, with sample orders shipped by air and trial orders shipped by bulk cargo. If you have any unclear questions, please contact the account manager.

Applications Of EN10219 S355NH 1/2 Steel Square Tubes

EN10219 S355NH 1/2 Steel Square Tube has been widely used in fields such as construction, bridges, machinery, ships, automobiles, and new energy due to its excellent performance.

In the field of construction, EN10219 S355NH 1/2 Steel Square Tubes is commonly used in structures such as beams, columns, supports, and frames to ensure the stability and safety of buildings with its high strength and excellent weldability.

In bridge engineering, EN10219 S355NH 1/2 Steel Square Tube is widely used in the main beams, crossbeams, and longitudinal beams of bridges due to its excellent fatigue resistance and wear resistance.

In the fields of machinery and shipbuilding,EN10219 S355NH 1/2 Steel Square Tube is used to manufacture various mechanical parts and ship structural components due to its high strength and excellent processability.

In addition, EN10219 S355NH 1/2 Steel Square Tube also plays an important role in the fields of automobiles and new energy.

FAQS

s355nh vs s355j2h

S355NH and S355J2H are both grades used for structural steel in the European standard EN 10025-4. The main difference lies in their application areas and performance characteristics:

S355NH: Typically used for structures that can withstand low temperatures and high strength, especially in applications that require welding and forming.

S355J2H: commonly used for manufacturing steel pipes, especially in cases where good toughness is required, suitable for structures that can withstand pressure and dynamic loads.

The chemical composition and mechanical properties of the two are different, so the selection should be based on the specific usage environment and requirements. It is recommended to carefully review the corresponding technical standards and data sheets before making a decision.

What is s355nh material?

S355NH is a low-alloy high-strength structural steel mainly used for applications that require high strength and toughness. This material is widely used in construction, bridges, pressure vessels, and other structural applications, and its characteristics include good weldability and mechanical properties such as tensile strength and yield strength. It is usually used in situations that require low-temperature toughness.