Zinc Aluminum Magnesium Coated Square Steel Tubes

- Model

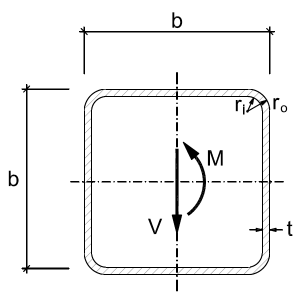

- Square Section Pipes

Item specifics

- Thickness

- 0.5- 3mm

- OD(Outer diameter)

- 10*10-200*200mm

- Certification

- CE,LEED,BV,PHD&EPD,BC1,EN 10210,EN10219,ISO9000

- Tolerance

- as required

- Length

- 0.5-24M according to client requirement

- Standards

- ASTM A500/A501,EN10219/10210,JIS 3466,etc

- Materials

- Gr.A,Gr.B,Gr.C,S235,S275,S355,S420,S460,A36

- Delivery Time

- 7-30 Days

Review

Description

Zinc Aluminum Magnesium Coated Square Steel Tubes

Overview

Zinc Aluminum Magnesium Coated Square Steel Tubes is a newly developed anti-corrosion steel pipe product. It has the advantages of strong anti-corrosion ability, light weight, self-healing cross-section, and affordable price. Widely used in the fields of new energy, greenhouse, mechanical equipment manufacturing, etc. The zinc aluminum magnesium coated square tube has been well received and praised by customers since its launch.

Zinc Aluminum Magnesium Coating Square Steel Tubes Sizes

The specifications of zinc aluminum magnesium coated square steel pipes that Yuantai Derun can produce are as follows: outer diameter range from 10 * 10-200 * 200mm, wall thickness range from 0.5-2.75mm, and length range from 0.5-24 meters. Of course, customers can also customize according to their own needs. For more information, please consult the customer manager.

|

Name

|

Outer Diameter(mm)

|

Wall Thickness(mm)

|

Length(M)

|

|

Zinc Aluminum Magnesium Coating Square Steel Tubes

|

10*10-200*200

|

0.5-2.75

|

0.5-24

|

Advantage Of Zinc Aluminum Magnesium Coating Square Steel Pipes

1. Strong corrosion resistance

Zinc aluminum magnesium coated square steel pipes have excellent corrosion resistance due to a layer of zinc aluminum magnesium coating on the surface, which can withstand acid, salt spray, and alkali environments. It has stronger corrosion resistance than ordinary pre galvanized square steel pipes.

2. Lightweight

Zinc aluminum magnesium coated square tubes belong to lightweight structural steel pipes, suitable for lightweight steel structure engineering.

3. Self repair function

The zinc aluminum magnesium coated square tube has self-healing function, reducing some maintenance costs.

4. Good weldability

Zinc aluminum magnesium coated square steel pipes have good welding performance, making them easy to connect and use in structures.

5. Easy to process

Zinc aluminum magnesium coated square tubes have excellent physical and mechanical properties, making them easy to process such as punching and bending.

Standards & Grade & Chemical Position

The steel grades, standards, and chemical composition of the zinc aluminum magnesium coated steel pipes produced by Yuantai Derun are shown in the following table:

|

Steel Grade

|

Chemical Composition (Mass Fraction)% |

||||

C | Si |

Mn

|

P

|

S

|

|

Not More Than |

|||||

|

S220GD+ZM

S250GD+ZM S280GD+ZM S320GD+ZM S350GD+ZM S390GD+ZM S420GD+ZM S450GD+ZM S550GD+ZM |

0.20 | 0.60 |

1.70

|

0.050

|

0.035

|

Zinc Aluminum Magnesium Coated Square Steel Pipes Forming Process

Zinc Aluminum Magnesium Coated Square Steel Pipes Forming Process include those main steps:

Zinc aluminum magnesium steel coil uncoiling ->edge cutting and butt welding ->straightening ->circular storage ->roll cold forming ->high-frequency welding ->removal of excess welding bars ->water cooling ->sizing ->cutting ->testing ->packaging and storage

Free Zn Al Mg Coated Square Tube Samples For You

In order to let users understand the quality of Zn Al Mg Coated Square Tubes, Yuantai Derun can make free samples for you. The sample length should be within 20 centimeters, and you only need to pay one shipping fee. Get free samples immediately.

ZAM Coating Square Tube Application

ZAM Coating Square Tubes have a wide range of applications and are suitable for various harsh environments. They have good corrosion resistance, wear resistance, coating resistance, and excellent welding processing performance. The application areas of zinc aluminum magnesium coated square steel pipes include but are not limited to:

1.Engineering construction: Used for supporting and framing building structures, providing stable support.

Glass curtain walls and door and window decorations: provide a beautiful appearance and excellent corrosion resistance.

2.Steel structures and guardrails: used to construct sturdy protective structures.

Mechanical manufacturing, automotive manufacturing, and home appliance manufacturing: providing durable components and casings.

3.Shipbuilding and container manufacturing: used for the construction of ships and containers, providing excellent corrosion resistance.

4.Electricity, agricultural construction, and agricultural greenhouses: used for the construction of power transmission lines and agricultural facilities.

5.Bicycle racks, motorcycle racks, shelves, fitness equipment, leisure travel supplies, steel furniture: providing durable and aesthetically pleasing furniture and equipment.

6.Firefighting and scaffolding, buildings, etc.: used for supporting firefighting equipment and building structures.