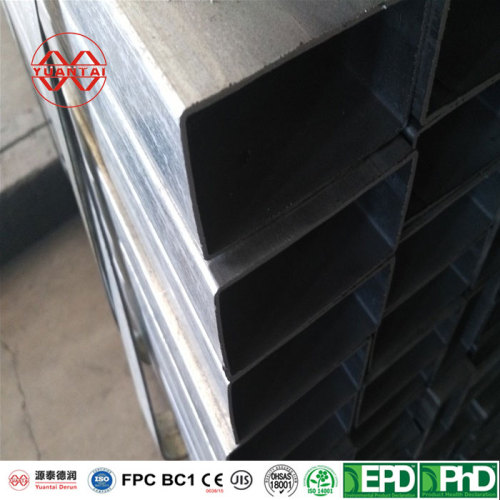

Mining pipes (steel pipes for supporting frames in mining tunnels)

- Model

- hfw-yt-098

Item specifics

- Thickness

- 0.5-60mm

- OD(outer diameter)

- 10*10-1200*1200mm 10*15-800*1200mm

- Grade

- Gr.A/B/C,S235/275/355/420/460,A36,ss400,STKR490

- Surface

- Customers't Requirement

- Delivery Time

- 7-30 Days

- Standards

- Hollow section: ASTM A500/A501,EN10219, EN10210etc

- Length

- 0.5-24M according to client requirement

- Brand

- YUANTAI DERUN

- Tolerance

- standard or as required

- Certification

- CE,LEED,BV,PHD&EPD,BC1,EN10210,EN10219,ISO9000,etc

Review

Description

Mining pipes (steel pipes for supporting frames in mining tunnels)

Overview

At Yuantai Derun, the mining and drilling industry is a particularly focused area. We produce a wide variety of pipes that meet almost all applications in the mining industry. The typical end uses of our pipes include: mining machinery and equipment, structural support for mining tunnels, and so on.

Yuantai Derun Steel Pipe Manufacturing Group has accumulated over 21 years of experience in manufacturing specialized pipes for the mining and drilling industries. These pipes are manufactured according to the highest industry standards and undergo rigorous testing. Therefore, we can almost guarantee that our pipes will be superior to any other pipe in the industry and more durable.

1.Comprehensive Process Control

At Yuantai Derun, we believe that the only way to ensure quality is to be responsible for the entire production process of mining steel pipes. Therefore, all of our raw materials are from large factories, and we have adopted a strict inspection process for the raw materials. We apply over 21 years of experience in manufacturing structural steel pipes to all our manufacturing processes and all steel products (we are one of the few selected manufacturers globally to obtain PHD and EPD approval to supply structural steel pipes).

We produce steel pipes through high-frequency welding production lines. The raw materials have been carefully selected and prepared to ensure the highest performance standards. All heats undergo ladle refining and vacuum degassing before continuous casting and rolling. Throughout the entire steel pipe production process, we maintain complete traceability of materials and records of strictly controlled process parameters. This super first-class raw material is the starting point for our mining pipe manufacturing.

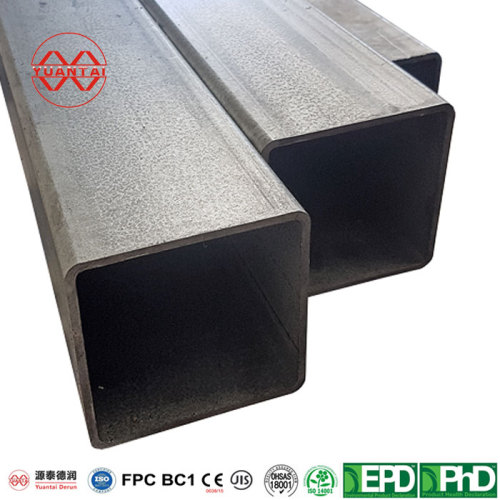

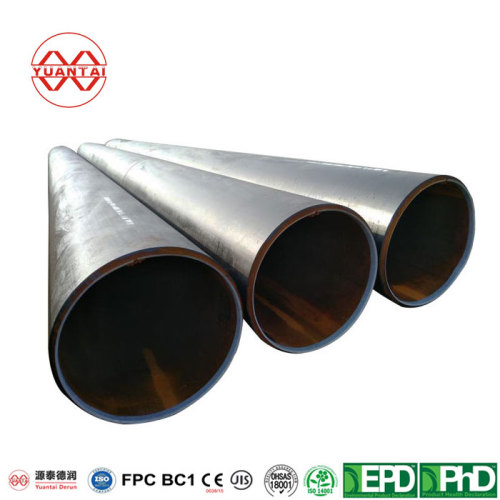

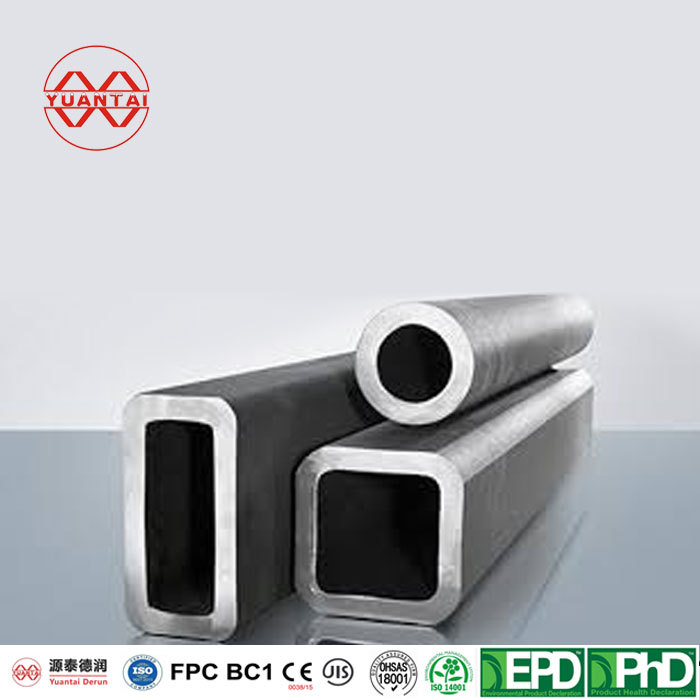

The manufacturing of steel pipes for precision mining not only depends on experience and process technology, but also on equipment. At Yuantai Derun, we believe in investing in the best equipment. In order to manufacture pipes for mines, we operate 65 high-frequency welded steel pipe production lines, one JCOE straight seam submerged arc welded steel pipe production line, spiral pipe production line and cold drawing workbench. Our tube mill is imported, and the forming process of the steel pipe adopts the best technology. In terms of experience, our team is one of the most technically qualified in the world, and the pipes we produce for the mining industry reflect this experience.

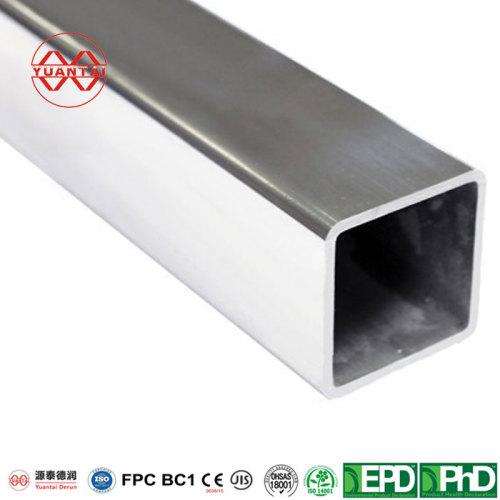

2.First class tolerances

Yuantai Derun provides the strictest tolerances in the industry. The reason why we are able to do this is because we have developed proprietary processes. For example, to ensure strict control of eccentricity (+/-5%), we provide a very high cross-sectional reduction during the cold drawing process. Similarly, Yuantai Derun uses its own developed special surface treatment process to ensure good dimensional control and surface cleanliness after heat treatment. Similarly, to ensure good surface finish, all cold drawing molds of Yuantai Derun are made of special materials (such as tungsten carbide) or coated with TiN. For applications that require excellent surface finish, we also offer bright annealed tubes.

3.Product details

Yuantai Derun's mining steel pipes are manufactured according to the following standard specifications, grades, dimensions, and tolerances. In addition to standard pipes, we also produce steel pipes according to customer specific requirements.

For drill pipe, Yuantai Derun has developed a unique process that allows us to ensure an extremely low residual circumferential stress of 65 MPa (maximum). More information about this special product (used for very demanding drilling conditions) can be provided upon request.

Yuantai Derun understands the importance of pipeline straightness in the mining industry. Therefore, we conduct a strict 5-point TIR straightness check and correction program for each pipe, paying special attention to the straightness of the pipe end. By doing so, we ensure a straightness of 1/6000 or better.

Pipe orifice leveling

1 IN 6000 straightness

Uniform thickness

High yield

Low residual circumferential stress

Safe transportation in its own fleet

4. Specification table for mining pipes