Galvanized Steel Round Tubing

- Model

- GI round tubing

Item specifics

- Thickness

- 0.5- 16 mm

- OD(outer diameter)

- 10.3mm-3620mm

- Tolerance

- as required

- Length

- 0.5-24M according to client requirement

- Standards

- ASTM A500/A501,EN10219,EN10210, JI

- Materials

- Gr.A,Gr.B,Gr.C,S275J0H,S355JR,S355J0H,S355J2H,A36,

- Packaging

- Customers't Requirement

- Delivery Time

- 7-30 Days

Review

Description

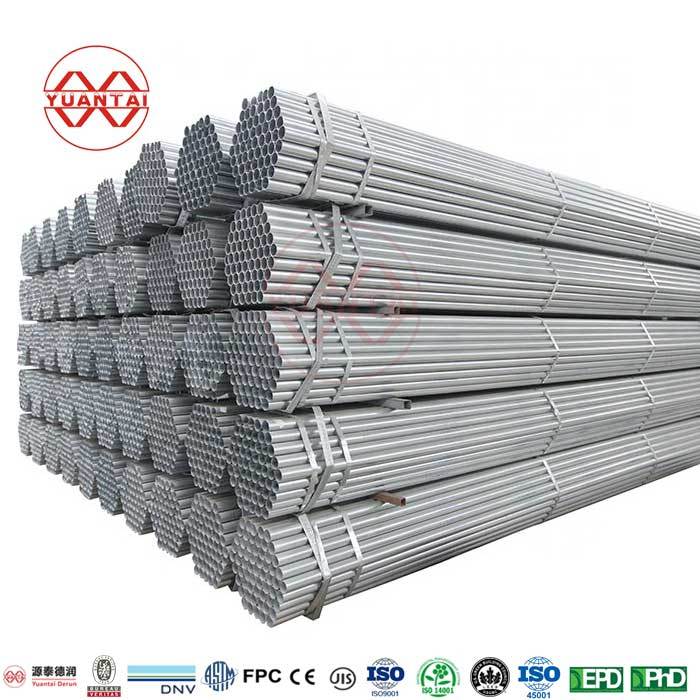

Galvanized Steel Round Tubing

Galvanized Steel Round Tubings can be divided into two categories: hot-dip galvanized steel round tubings and galvanized strip round pipes. Galvanized steel round tubing have better corrosion resistance and oxidation resistance than ordinary black round pipes.

Two Type Of Galvanized Steel Round Tubing

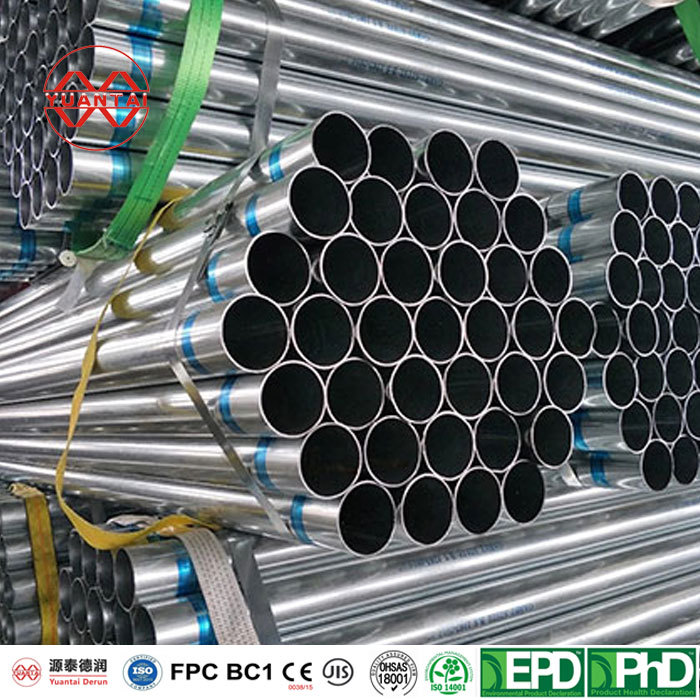

At Yuantai Derun ,we can produce 2 type of galvanized steel round tubing,one is pre galvanized Round steel tubing ,another one is the Hot-Dip Galvanized Steel Round Tubings.

Pre Galvanized Round Steel Tubing

Hot-Dip Galvanized Steel Round Tubings

Application Of Galvanized Round Tubings

Galvanized steel round tubings are widely used in manufacturing industries such as construction, machinery, coal mining, chemical engineering, electricity, railway vehicles, automotive industry, highways, bridges, containers, sports facilities, agricultural machinery, petroleum machinery, and mining machinery.

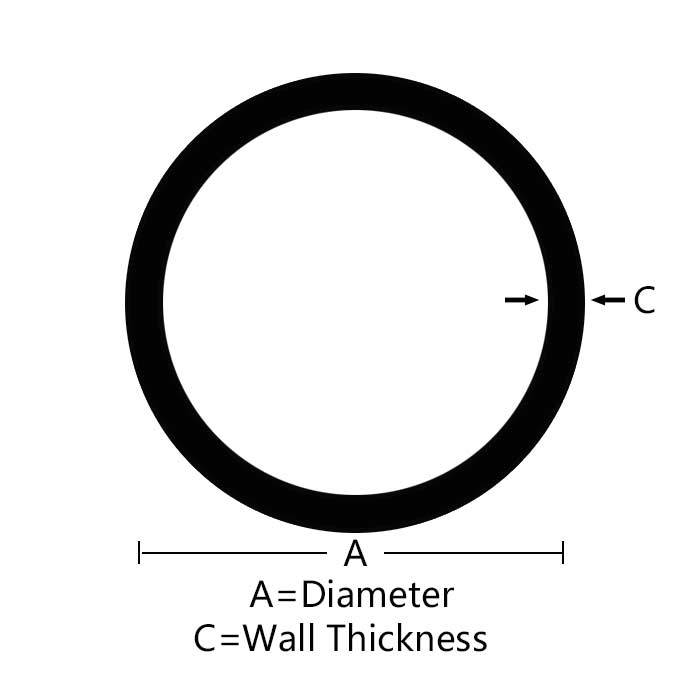

Complete Galvanized Round Tubing Sizes For You

Let us to see galvanized steel round tubing sizes

(1)Pre Galvanized Steel Round Tubing Sizes

|

Size

|

O.D.(mm) | THK(mm) | Minimum wall thickness |

weld pipe(6m)

|

galvanized pipe

|

||

Nominal inner diameter | inch | Meter weight kg | Piece weight kg | Meter weight kg | |||

DN15 | 1/2 | 21.3 | 2.8 | 2.45 | 1.28 | 7.68 | 1.357 |

DN20 | 3/4 | 26.9 | 2.8 | 2.45 | 1.66 | 9.96 | 1.76 |

DN25 | 1 | 33.7 | 3.2 | 2.8 | 2.41 | 14.46 | 2.554 |

DN32 | 1.25 | 42.4 | 3.5 | 3.06 | 3.36 | 20.16 | 3.56 |

DN40 | 1.5 | 48.3 | 3.5 | 3.06 | 3.87 | 23.22 | 4.10 |

DN50 | 2 | 60.3 | 3.8 | 3.325 | 5.29 | 31.74 | 5.607 |

DN65 | 2.5 | 76.1 | 4.0 | 3.5 | 7.11 | 42.66 | 7.536 |

DN80 | 3 | 88.9 | 4.0 | 8.38 | 50.28 | 8.88 | |

DN100 | 4 | 114.3 | 4.0 | 10.88 | 65.28 | 11.53 | |

DN125 | 5 | 140 | 4.5 | 15.04 | 90.24 | 15.942 | |

|

DN150

|

6 | 168.3 | 4.5 |

18.18

|

109.08

|

19.27

|

|

|

DN200

|

8 | 219.1 | 6.0(welded pipe) |

31.53

|

189.18

|

||

|

DN200

|

8 | 219.1 | 6.5(HDG pipe) |

36.12

|

|||

(2)Hot Dip Galvanized Steel Round Tubing Size

Φ:10.3-3620mm

Wall thickness:0.5-60mm

Length:0.5-24M or customized

For more information,please contact our sales manager:sales@ytdrgg.com

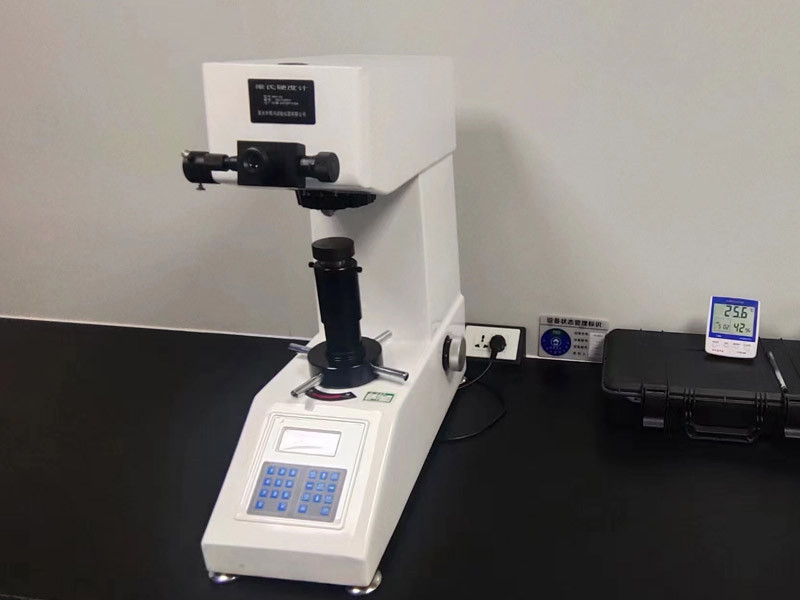

4、How to judge the quality of hot-dip galvanized round tubing?

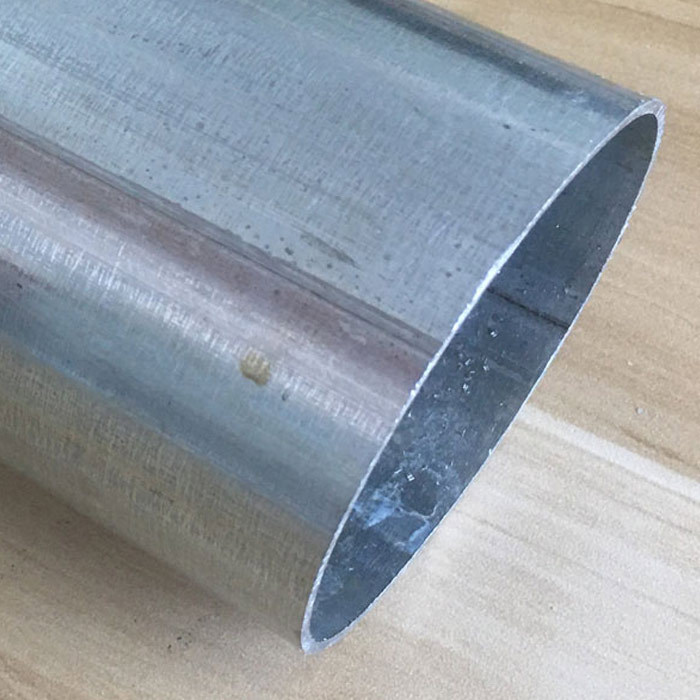

(1) Appearance of galvanized pipe fittings

The surface of high-quality galvanized pipe fittings should have a complete coating, consistent color, uniform transition, and no sags, drips, or excess lumps on the surface. The surface of the pipe fittings shall not have defects such as missed plating or exposed iron.

(2) Galvanized layer thickness

The thickness of the zinc layer on galvanized pipes is an important indicator for judging the quality of galvanizing, usually measured in units μ M represents the weight of the galvanized layer per square meter (g/m2), and the conversion formula is: 1g/m2=0.14 μ M. Due to the different magnetic and polarizability between zinc and steel, the determination of zinc layer thickness can be non-destructive measured using a zinc layer thickness gauge. To determine the weight of the zinc layer, it is necessary to scrape and sample the zinc layer, and measure it using chemical methods such as antimony chloride method.

The customer manager of Yuantai Derun will also remotely connect with customers on-site to measure the thickness of the zinc layer.

(3) Uniformity of zinc coating

The high-quality galvanized layer has a uniform texture and no leakage or damage after plating. The galvanized pipe fittings can be immersed in a certain concentration of copper sulfate solution for a certain number of times and time. If there is no red leaching substance (metal copper) on the surface, it can be considered that the galvanized pipe fittings have no leakage or damage defects after plating.

(4) Adhesion of zinc coating

The adhesion of the galvanized layer is a standard for measuring the firmness of the bonding between the galvanized layer and the steel pipe. After soaking the steel pipe in a zinc bath for a certain period of time, the surface of the steel pipe will react with the galvanized liquid to form a zinc iron mixed layer. A scientifically sophisticated galvanizing process will form a zinc iron mixed layer with sufficient thickness to improve the adhesion of the zinc layer. The adhesion of the galvanized layer can be monitored by lightly tapping with a rubber hammer, preferably to ensure that the coating does not fall off after a certain number of taps.

5.Galvanized Round Tubing Advantages And Features

long service life

Yuantai Derun steel pipe has long service life

The steel pipe surface is smooth

The surface of the steel pipe shall be smooth without burrs

No joint, no cushion bar

There is no joint and backing bar in the finished steel pipe

Source of raw materials

Large factory direct supply

Each steel pipe 100% complies with international standards

Each steel pipe is inspected layer by layer

OEM&ODM&OBM

Yuantai derun accepts OEM,ODM,OBM

6、One Corner of Yuantai Derun Workshop

7.Strict Product inspection

Each steel pipe must pass the inspection layer by layer. Only the products that pass the inspection can leave the factory. Never let an unqualified product flow into the market

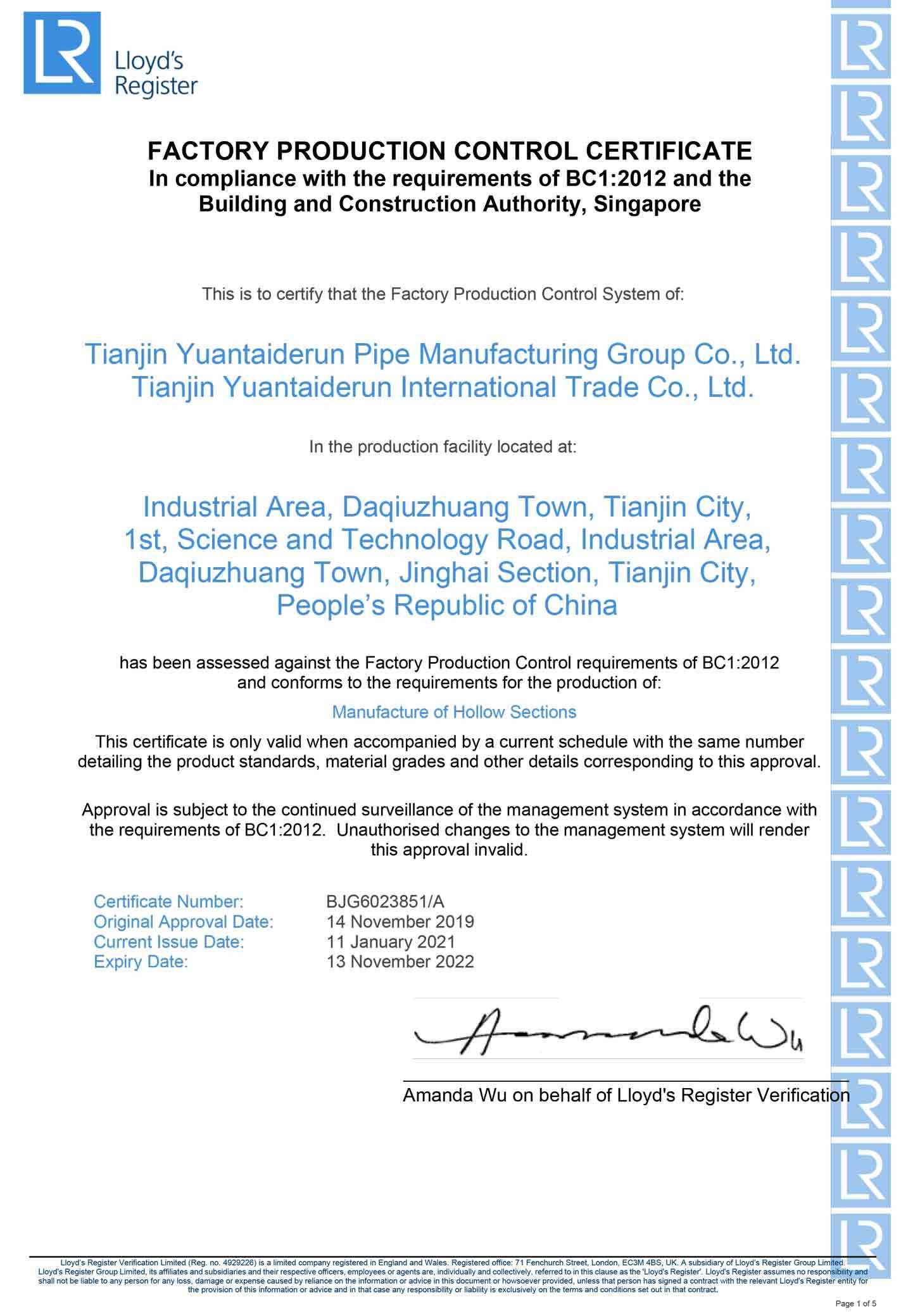

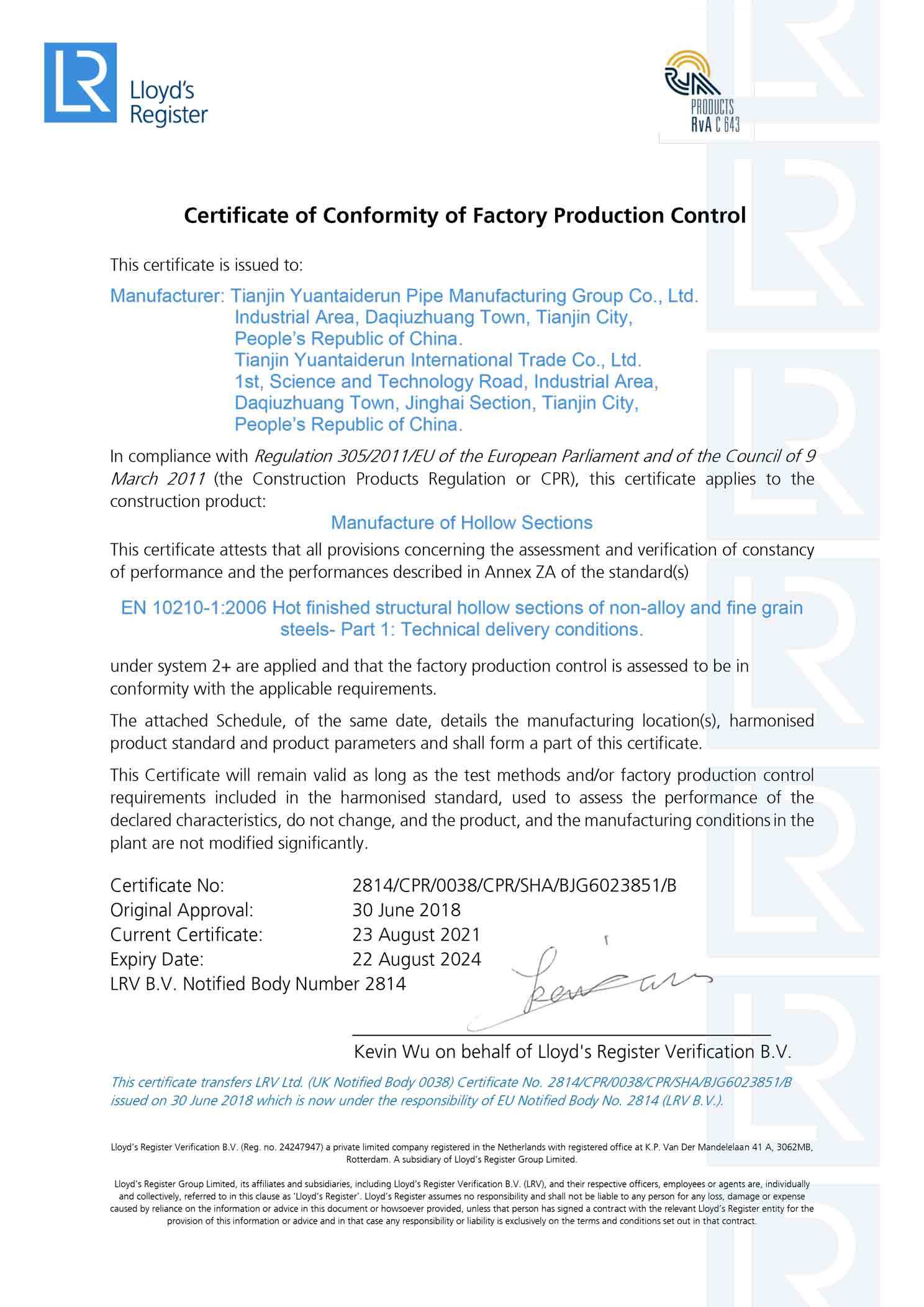

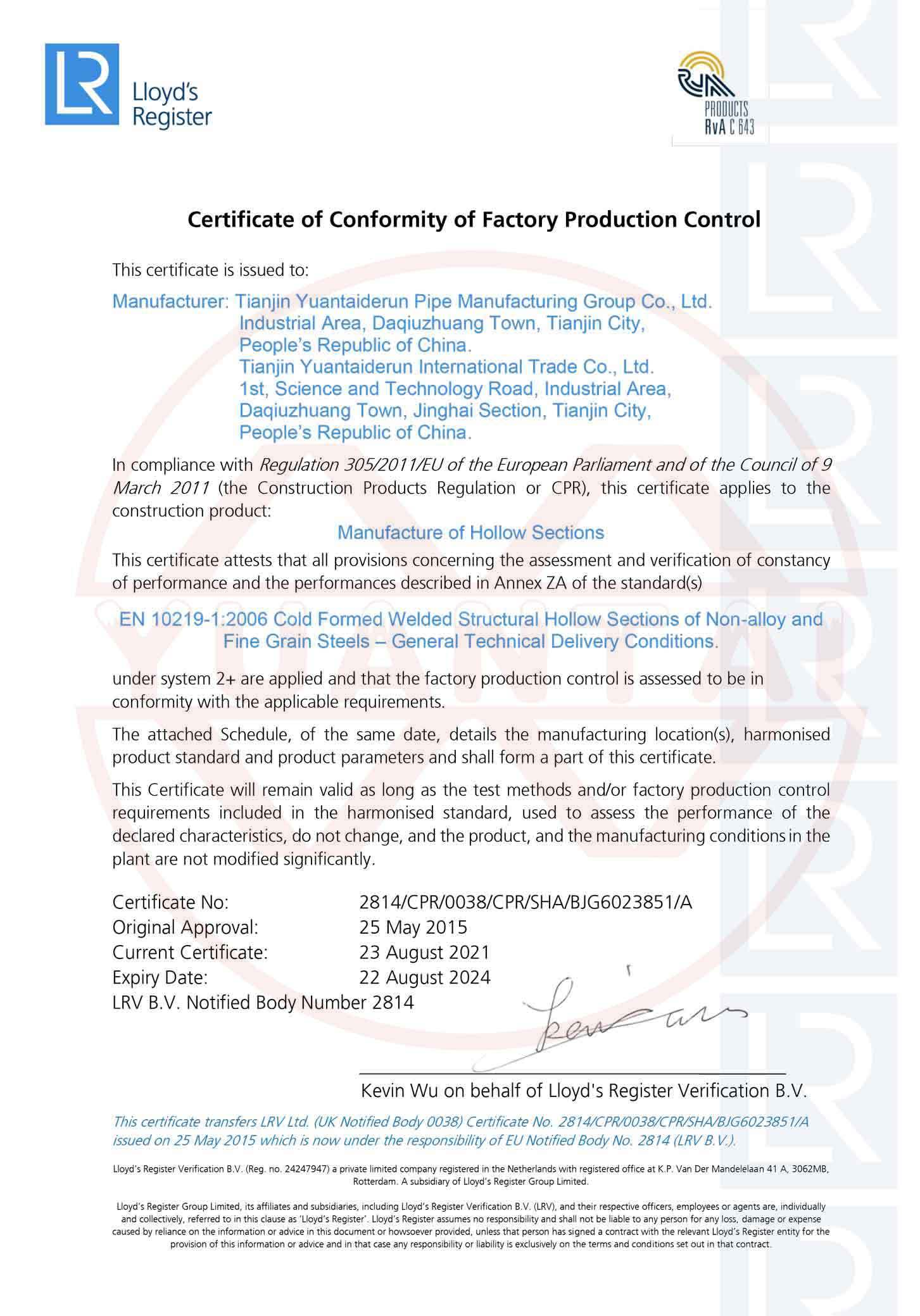

8.Certificate

BC1

FACTORY PRODUCTION CONTROL CERTIFICATE,ln compliance with the requirements of BC1:2012 and the Building and Construction Authority, Singapore

EN10210

Manufacture of Hollow Sections :This certificate proves that the performance stability meets the performance of European standards

EN10219

Manufacture of Hollow Sections :This certificate proves that the performance stability meets the performance of European standards

BV

This certficate is issued to attest that Bureau Vveritas Marine & Ofishore has perormed, at the above company's request and in compliance withthe requirements of NR320,a satisfactory assessment of the manudacturing facilities and associated quality procedures related to the ranrge of therecogniition.

EPD

Environmental Product Declaration

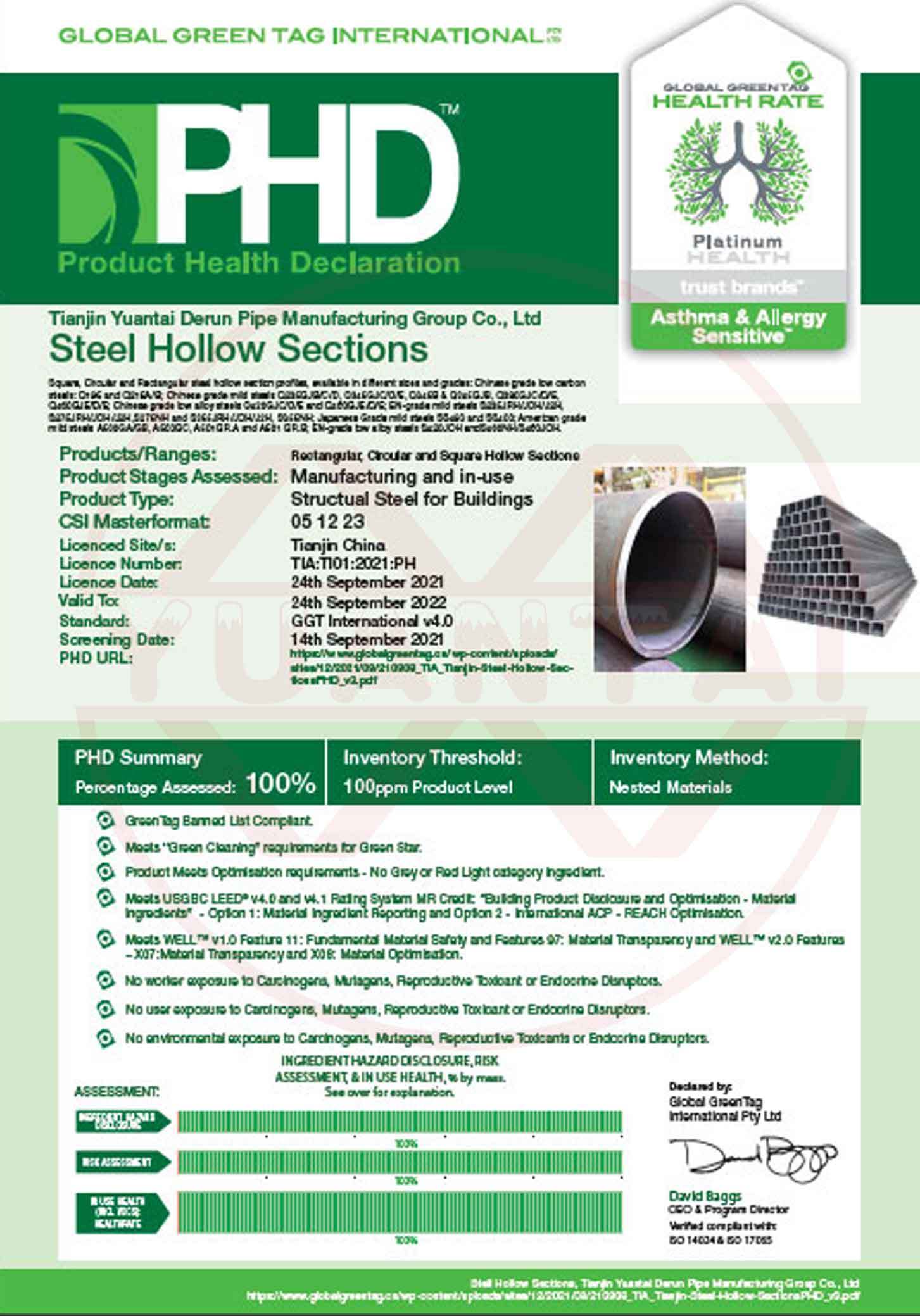

PHD

Product Health Declaration

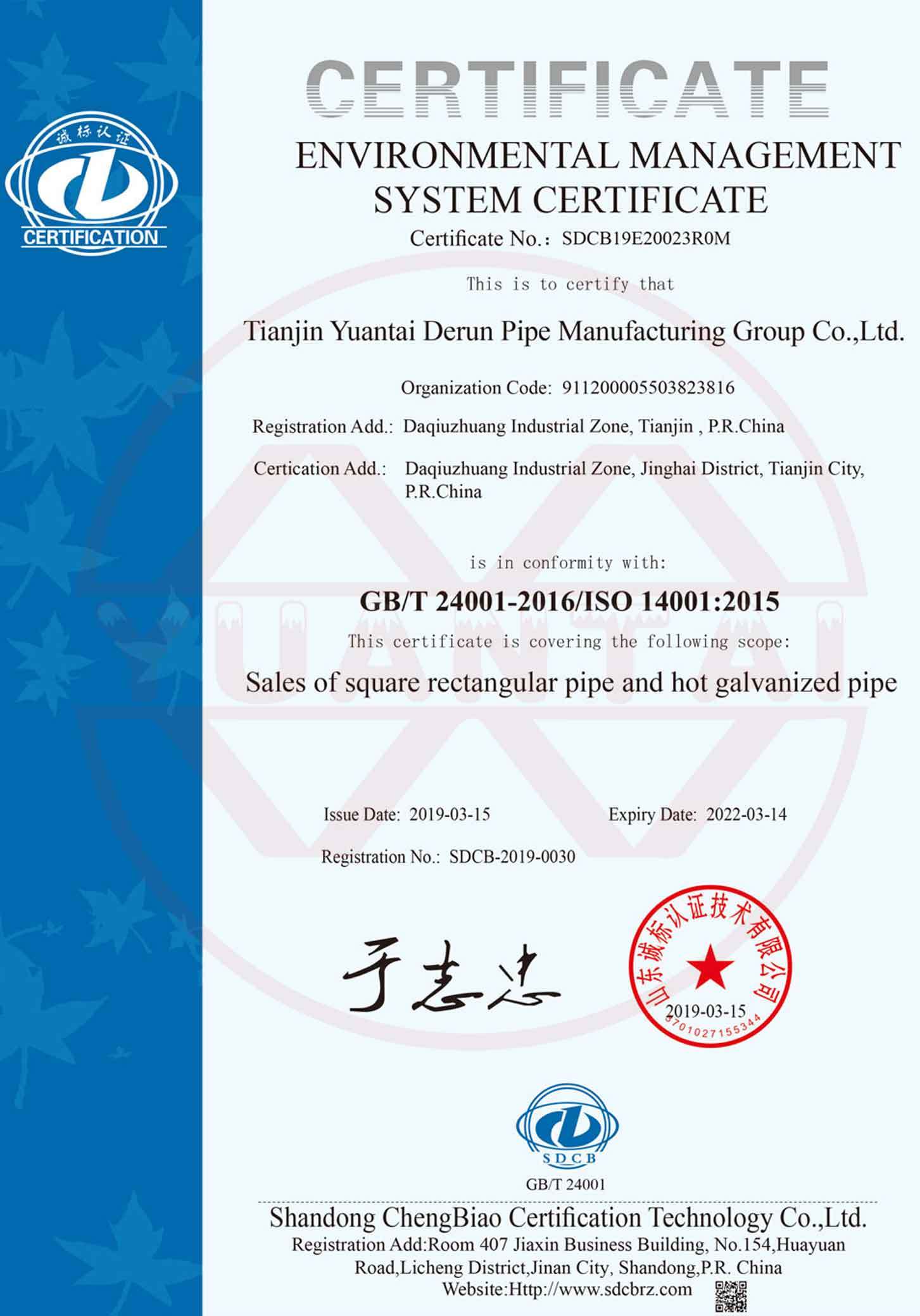

ISO14001(GB/T 24001)

ENVIRONMENTAL MANAGEMENT SYSTEM CERTIFICATE

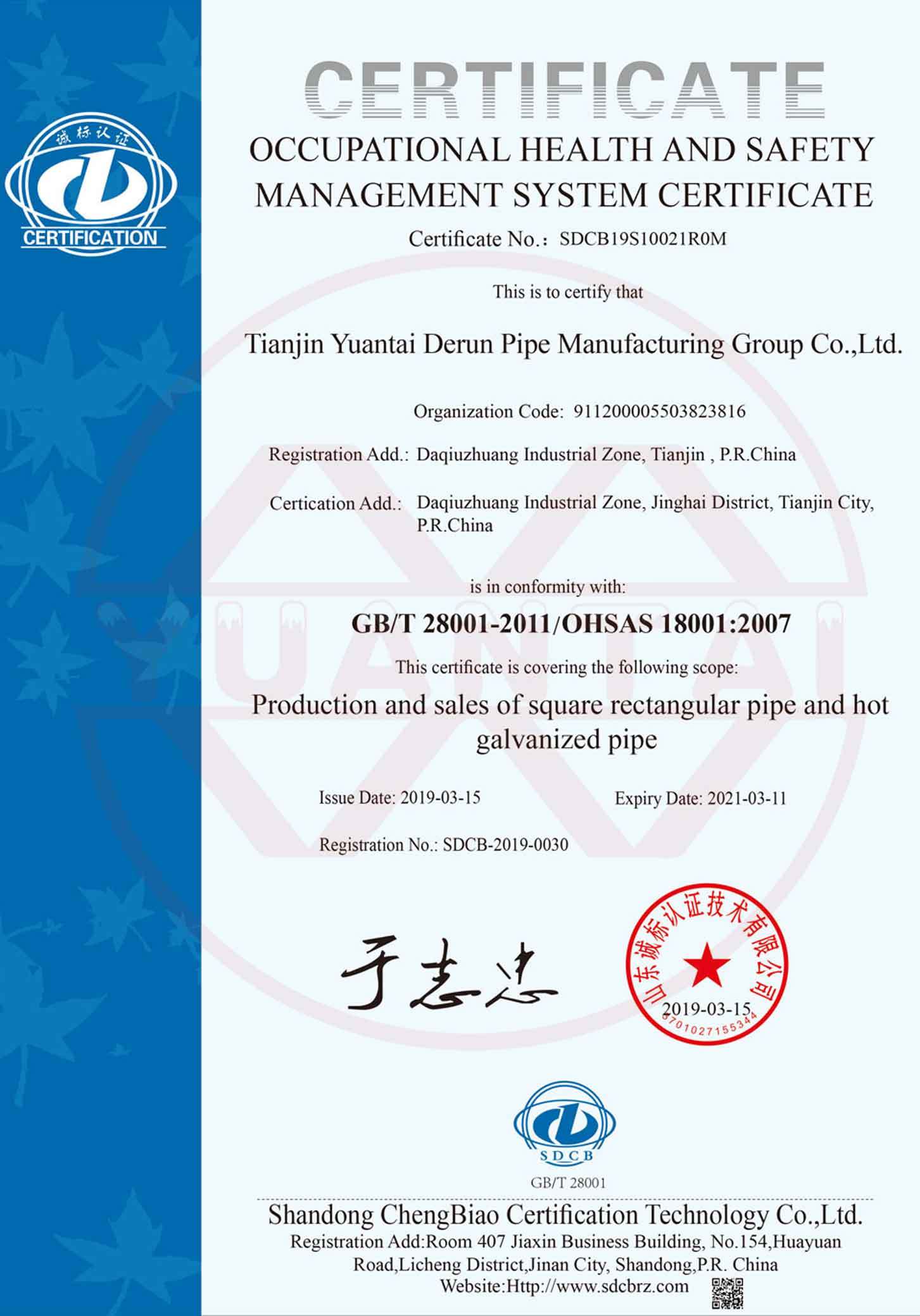

OHSAS 18001(GB/T28001-2011)

OCCUPATIONAL HEALTH AND SAFETYMANAGEMENT SYSTEM CERTIFICATE

ISO9001(GB/T19001)

The production of rectangular pipe and hot-dip galvanized pipe, the sales and service of metal materials, and the quality management system meet the requirements

GB / t19001-2016 / iso9001:2015

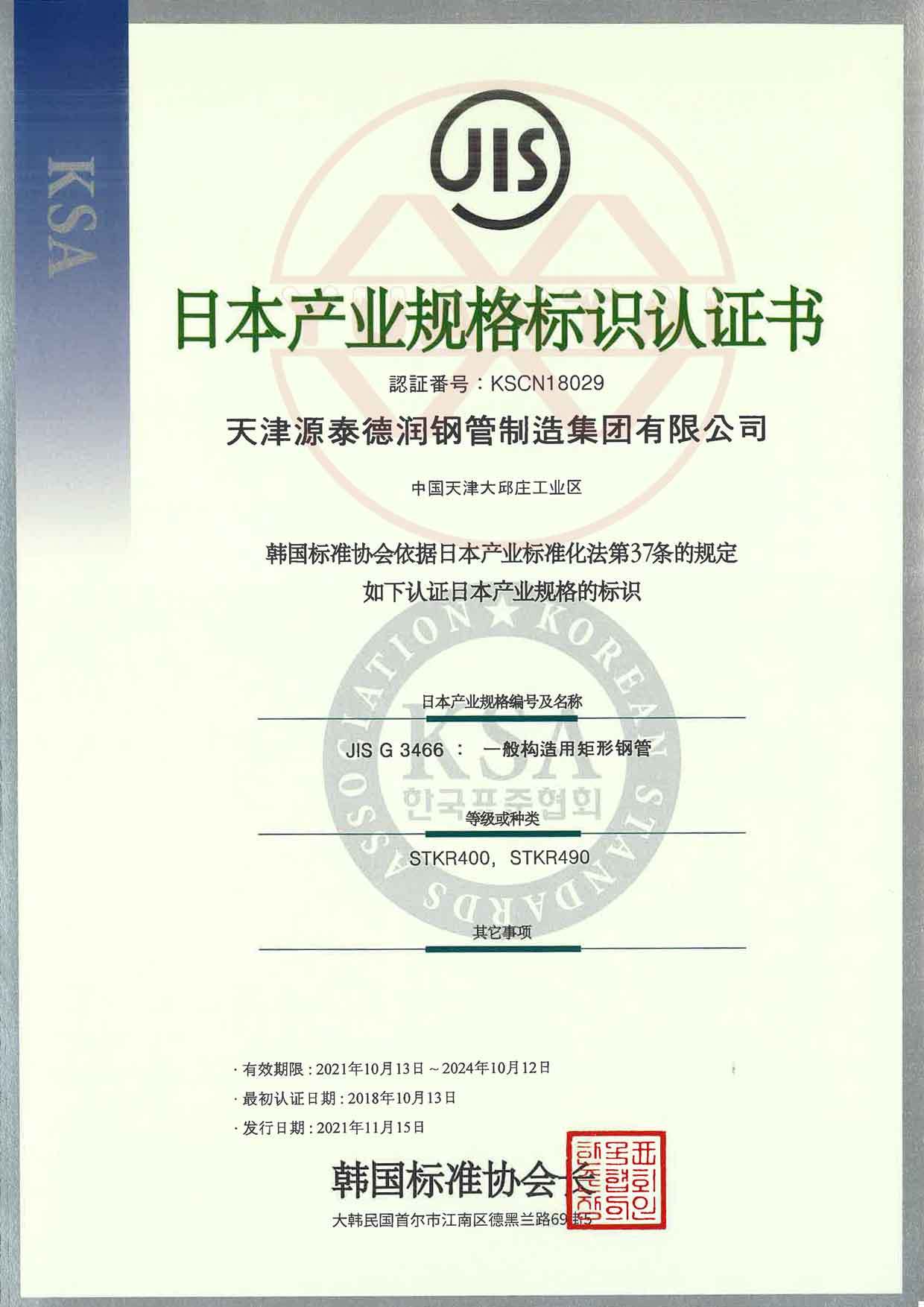

JIS G3466

Jis G 3466 : Carbon steel square and rectangular tubes for general structure meet JIS G3466 standard

9. Value Added Services

The galvanized round pipes produced by Yuantai Derun can also provide you with the following value-added services:

1. Punching holes

2. Cutting

3. Welding

4. Bending

5. Anti corrosion and insulation treatment

6. Pipe end threading

Warmly welcome global steel pipe buyers to contact us. Order or consult.