erw sch 80 carbon steel pipe

- Model

- sch 80 steel pipe

Item specifics

- Thickness

- 0.5- 16 mm

- OD(outer diameter)

- 10.3mm-609mm

- Supply capacity

- Annual output of 5 million tons

- Certification

- CE,LEED,BV,PHD&EPD,BC1,EN10210,EN10219,ISO9000,AST

- Surface Treatment

- REQUEST

- Tolerance

- as required

- Length

- 0.5-24M according to client requirement

- Materials

- Gr.A,Gr.B,Gr.C,S275J0H,S355JR,S355J0H,S355J2H,A36,

- Delivery Time

- 7-30 Days

Review

Description

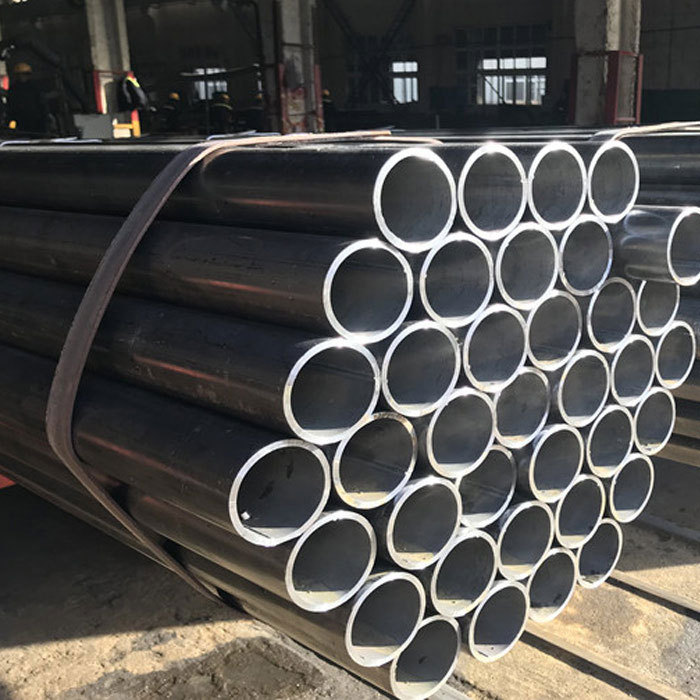

ERW Sch 80 Carbon Steel Pipe

SCH 80 carbon steel pipe refers to a specific wall thickness classification of carbon steel pipes. The "SCH" stands for "schedule," which represents the thickness of the pipe wall. SCH 80 pipes have a thicker wall compared to standard pipes, making them suitable for high-pressure applications and environments.

Yuantai Derun can produce all kinds of Sch 80 Carbon Steel Pipe,high quality,low cost,fast delivery.

And Yuantai Derun can accept flexible customization requirements for Sch 80 Carbon Steel Pipe.

Advantages Of SCH 80 Carbon Steel Pipe

- Enhanced strength and durability: The thick wall of SCH 80 carbon steel pipes provides exceptional strength and rigidity, ensuring they can withstand high-pressure conditions.

- Corrosion resistance: Carbon steel pipes are known for their resistance to corrosion, which extends the lifespan of the pipes and reduces maintenance costs.

- Cost-effective: SCH 80 carbon steel pipes offer a cost-effective solution due to their long-term durability and low maintenance requirements.

Applications Of SCH 80 Carbon Steel Pipe

CH 80 carbon steel pipes find applications in various industries, including:

- Oil and gas exploration and transportation

- Chemical processing plants

- Power generation facilities

- Construction and infrastructure projects

- HVAC systems

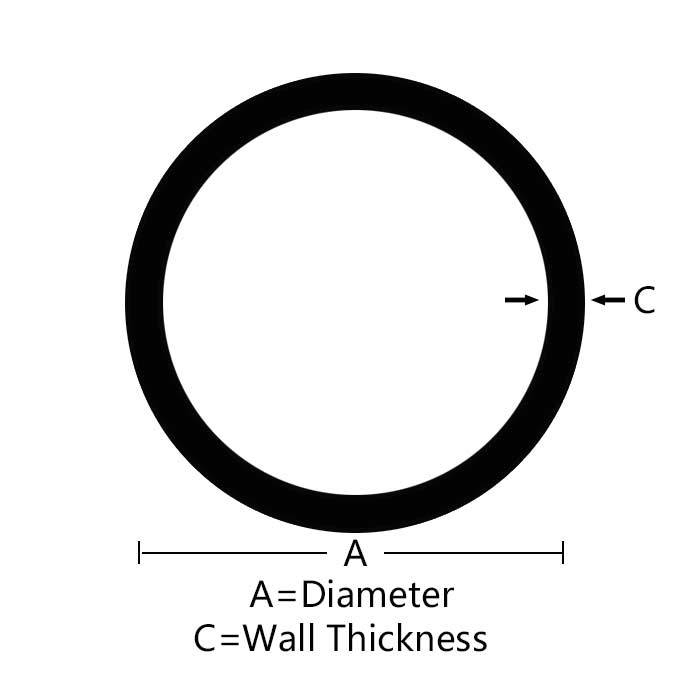

Complete Sch 80 Steel Pipe Dimensions For You

At Yuantai Derun, the SCH 80 Carbon Steel Pipe Dimensions that can be produced and customized are very complete, with various types of SCH 80 steel pipe dimensions shown in the table below.

|

Making Process

|

sch 80 steel pipe outer diameter

|

sch 80 steel pipe wall thickness

|

sch 80 steel pipe length

|

|

ERW

|

10.3-609mm

|

0.5-16mm

|

0.5-24M

|

|

LSAW

|

355.4-1420mm

|

4-30mm

|

0.5-24M

|

|

SSAW

|

219-3620mm

|

5-30mm

|

0.5-26.5M

|

Seamless | 21.3-820mm | 0.5-60mm | 0.5-24M |

Customization Options

At Yuantai Derun, you can flexibly customize SCH 80 Carbon Steel Pipe with the following customization options.

- Outer diameter

- Wall Thickness

- Length

- Steel grade: Gr.A/B/C,S235/275/355/420/460,A36,SS400,Q195/235/345,X42/52/60/65/70,STKR400/490,300W/350W

- coating:oil,painted,galvanized,etc

Comparison Table for Sch Size of Carbon Steel Pipe(Sch 80 Carbon Steel Pipe Specification Table)

|

Nominal diameter DN

|

Outside diameter(O.D.)

|

Nominal Wall Thickness

|

|

|

A-series

|

B-series

|

SCH80

|

|

|

15

|

21.3

|

18

|

3.6

|

|

20

|

26.9

|

25

|

4.0

|

25 | 33.7 | 32 | 4.5 |

32 | 42.4 | 38 | 5.0 |

40 | 48.3 | 45 | 5.0 |

50 | 60.3 | 57 | 5.6 |

65 | 76.1 | 76 | 7.1 |

80 | 88.9 | 89 | 8.0 |

90 | 101.6 | - | 8.0 |

100 | 114.3 | 108 | 8.8 |

125 | 139.7 | 133 | 10.0 |

150 | 168.3 | 159 | 11.0 |

200 | 219.1 | 219 | 12.5 |

250 | 273.0 | 273 | 16.0 |

300 | 323.9 | 325 | 17.5 |

350 | 355.6 | 377 | 20.0 |

400 | 406.4 | 426 | 22.2 |

450 | 457.0 | 478 | 25.0 |

500 | 508.0 | 529 | 28.0 |

550 | 559 | - | 30.0 |

600 | 610 | 630 | 32.0 |

Schedule 80 Carbon Steel Pipe Fittings Details:

More Types of SCH80 Carbon Steel Pipes You Choose

At Yuantai Derun,In addition to SCH 80 pipes and ERW pipes, there are several other types of carbon steel pipes available we can produce for you. These include seamless pipes, spiral welded pipes, and galvanized pipes.

ERW SCH80 Carbon Steel Pipe

LSAW SCH80 Carbon Steel Pipe

SSAW SCH80 Carbon Steel Pipe

SCH 80 Seamless Steel Pipe

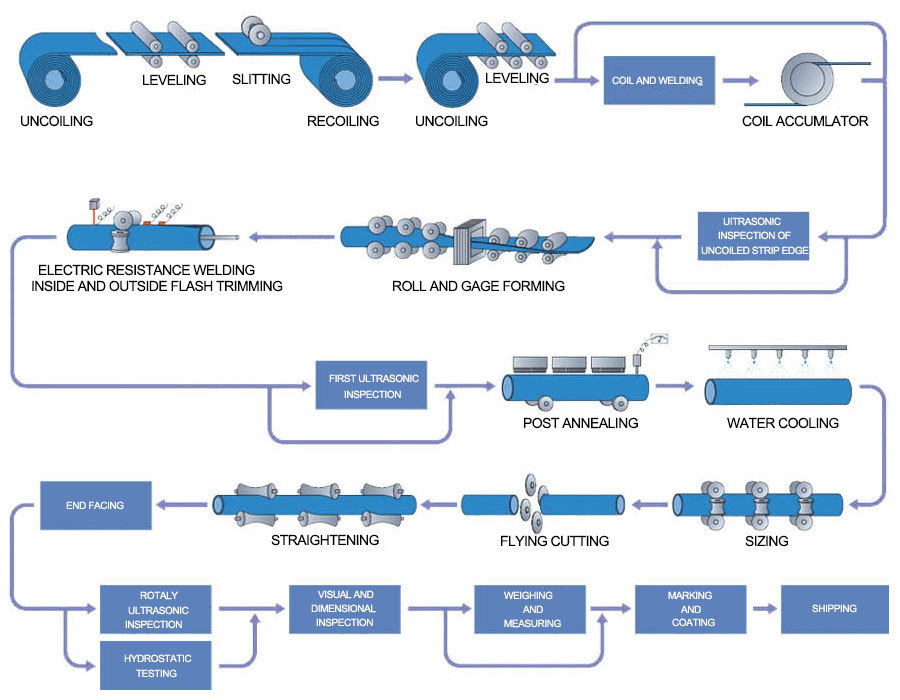

ERW SCH 80 Carbon Steel Pipe Making Process

Why Choose Yuantai Derun Group?

Selecting a reputable carbon steel pipe manufacturer is crucial to ensure the quality, reliability, and longevity of the pipes used in various applications. Yuantai Derun is a reliable Carbon Steel Pipe Manufacturer Our Advantage include:

- Manufacturing capabilities and facilities(5000000 Tons/Year)

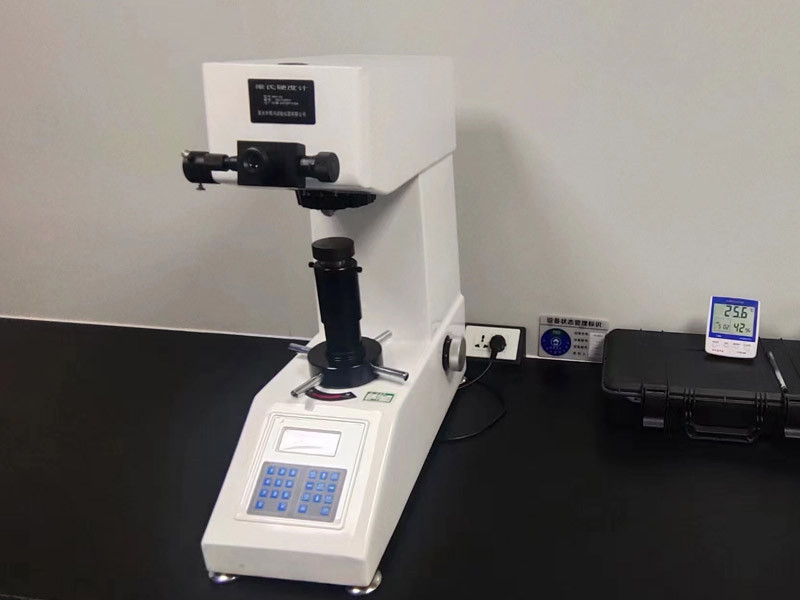

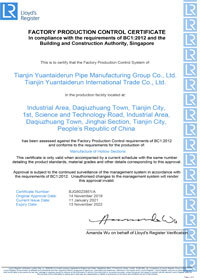

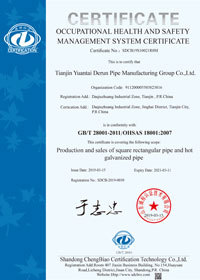

- Quality control processes(CNAS certified test center)

- Compliance with industry standards and certifications(ISO9001/ISO14001/ISO45001,EN10219/EN10210,JIS G3466,BV,DNV,PhD,EPD,BC1,ABS,API 5L,etc)

- Reputation and customer reviews(Yuantai Derun Group has many years of project supply experience, and many well-known projects at home and abroad have been supplied with Yuantai Derun steel products, which have received unanimous praise from domestic and foreign users. )

- Customization options and OEM/ODM/OBM services

(75 black HFW steel pipe production lines,JCOE productiong lines,3 SSAW production lines,6 ZAM coated production lines,8 PV support production lines,10 hot dip galvanized production lines )

Accept OEM, ODM in the Carbon Steel Pipe Orders

Yuantai Derun can accept orders for OEM, ODM service from Carbon Steel Pipe users worldwide, send OEM/ODM request immediately.

Benefits of OEM, ODM Services

- OEM: Allows businesses to develop their own brand by customizing products according to their specifications.

- ODM: Offers ready-made designs with the option to customize certain aspects of the product.

Strictly ERW SCH 80 Carbon Steel Pipe Testing

In Yuantai Derun, the ERW SCH 80 Carbon Steel Pipe products are strictly tested according to customers' requirements, and the common tests include chemical composition test, ultrasonic flaw detection, metallographic test, yield strength test, impact test, tensile test, hardness test, X-ray test, hydraulic test and so on. We ensure that our customers' steel pipe products are qualified.

Free SCH80 Carbon Steel Pipe Samples For You

At Yuantai Derun,For new SCH80 steel pipe buyers, we have free sample service, as long as the length of the sample is within 20cm, customers only need to pay one shipping fee to get our free sample. Get your free sample now.

Accept Small And Trial Orders

At Yuantai Derun, in order to make it more convenient for users to know the quality of the products, the group is able to accept orders or small orders to send your needs immediately.

Complete Certificates For Your Project

Yuantai Deloitte, as your SCH80 steel pipe exporter, plays an important role not only in connecting manufacturers with international buyers. For example, we can facilitate the export process for you, handle logistics, ensure regulatory compliance, and provide support throughout the transaction, as well as have a full range of globally recognized steel pipe product certifications that can help you participate in the bidding process for your products. Send your project request today.

FAQS

Are SCH 80 carbon steel pipes suitable for high-temperature applications?

Yes, SCH 80 carbon steel pipes can withstand high temperatures and are suitable for applications where heat resistance is required.

Can SCH 80 carbon steel pipes be used for underground pipelines?

Yes, SCH 80 carbon steel pipes are commonly used for underground pipelines due to their durability and corrosion resistance.

What are the advantages of OEM services in the carbon steel pipe industry?

OEM services allow businesses to customize products according to their specific requirements, enabling them to establish their own brand identity.

Are ERW steel pipes more cost-effective than seamless pipes?

Yes, ERW steel pipes are generally more cost-effective compared to seamless pipes due to their production process and lower material costs.

How do I ensure the quality of carbon steel pipes before purchasing?

It is crucial to choose a reputable manufacturer who complies with quality standards, holds relevant certifications, and provides guarantees or warranties for their products.