a53 b erw pipe manufacturer China Tianjin YuantaiDerun

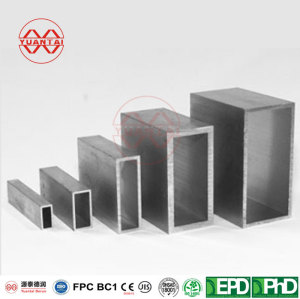

- Model

- astm a53 erw pipe

Item specifics

- Thickness

- 0.5- 16 mm

- OD(outer diameter)

- 10.3mm-609mm

- Supply capacity

- Annual output of 5 million tons

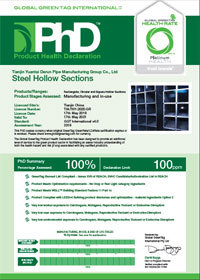

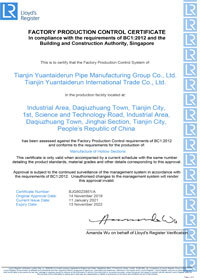

- Certification

- CE,LEED,BV,PHD&EPD,BC1,EN10210,EN10219,ISO9000,AST

- Surface Treatment

- REQUEST

- Tolerance

- as required

- Length

- 0.5-24M according to client requirement

- Standards

- Hollow section: ASTM A500/A501,EN10219,EN10210, JI

- Materials

- Gr.A,Gr.B,Gr.C,S275J0H,S355JR,S355J0H,S355J2H,A36,

Review

Description

a53 erw pipe manufacturer China Tianjin YuantaiDerun

Introduction:

ERW pipes, also known as Electric Resistance Welded pipes, are an essential component in numerous industries. They provide a cost-effective solution with excellent strength and durability. In this article, we will explore the different types of ERW pipes, their applications, benefits, and compare them with other pipe types.

What is ERW Pipe?

ERW pipes are fabricated by continuously welding longitudinally along the edges of a steel strip. The electric resistance heat generated during the welding process fuses the edges together, creating a seamless bond. The resulting pipe offers exceptional structural integrity and dimensional accuracy. ERW pipes are known for their high resistance to external forces and pressure.

One of the advantages of ERW pipes is their cost-effectiveness compared to other pipe manufacturing methods. The use of electric resistance welding ensures efficiency in production, thereby making ERW pipes affordable without compromising quality.

Understanding A53B ERW Pipe:

A53B ERW pipe is a type of ERW pipe that is specifically designed to meet the requirements of ASTM A53 Grade B. This pipe grade is widely used in various industries due to its excellent material properties. A53B ERW pipes exhibit high tensile strength and superior resistance to corrosion, making them suitable for different applications such as plumbing, agriculture, and construction.

The key benefits of using A53B ERW pipes include their ability to withstand high temperatures, compatibility with diverse environments, and ease of installation. These pipes are also known for their longevity, making them a reliable choice for long-term projects.

Exploring A53 Gr B ERW Pipe:

A53 Gr B ERW pipes are another variation of ERW pipes that conform to the requirements of ASTM A53 Grade B. These pipes are commonly used in applications requiring high-pressure fluid or gas transportation. A53 Gr B ERW pipes offer enhanced structural integrity and dimensional accuracy, ensuring optimal performance even in demanding environments.

One of the key advantages of using ASTM A53 ERW Steel Pipe is its cost-effectiveness. The affordability, combined with excellent structural integrity and reliability, makes these pipes a popular choice among engineers and contractors. Additionally, ASTM A53 ERW Steel Pipe exhibits exceptional weldability, facilitating efficient installation and repair processes.

Benefits of ASTM A53 ERW Steel Pipe:

ASTM A53 ERW Steel Pipe is widely recognized for its exceptional properties and performance. These pipes are constructed using high-quality steel, offering superior strength, durability, and resistance to corrosion. They are highly versatile and find applications in multiple industries, including construction, transportation, and manufacturing.

One of the key advantages of using ASTM A53 ERW Steel Pipe is its cost-effectiveness. The affordability, combined with excellent structural integrity and reliability, makes these pipes a popular choice among engineers and contractors. Additionally, ASTM A53 ERW Steel Pipe exhibits exceptional weldability, facilitating efficient installation and repair processes.

Understanding ASTM A53 ERW Pipe:

ASTM A53 ERW Pipe refers to electric resistance welded pipes manufactured according to the standards set by the American Society for Testing and Materials (ASTM). These pipes are widely used in various industries for applications such as structural support, liquid transportation, and mechanical purposes.

Compared to other types of pipes, ASTM A53 ERW Pipe offers distinct advantages. It provides increased dimensional accuracy, excellent weldability, and superior surface finish. The wide availability of different sizes and specifications further enhances its utility across diverse sectors.

Manufacturing and Production of ERW Pipes:

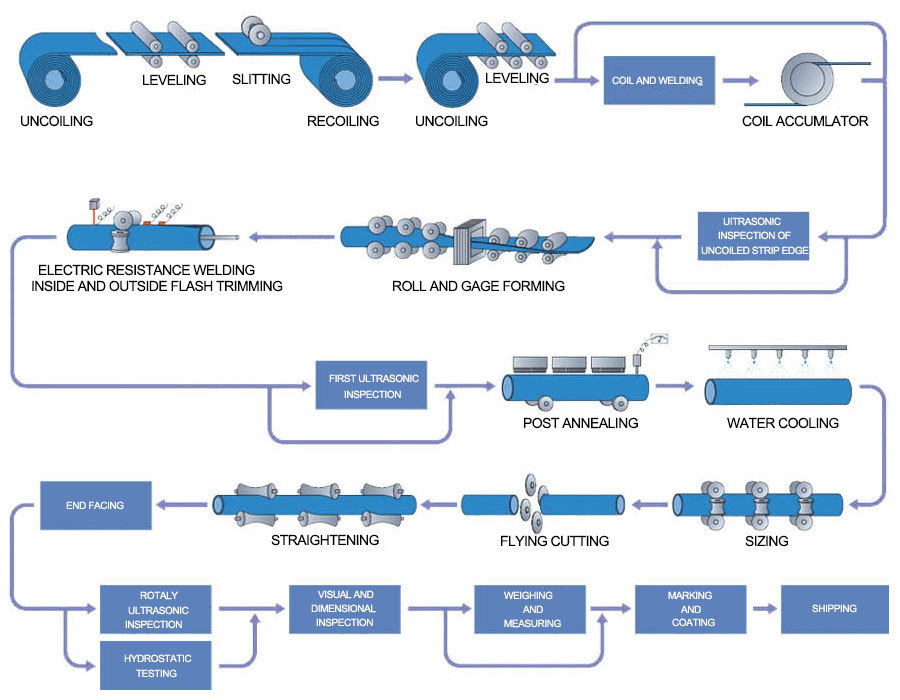

The manufacturing process of ERW pipes involves several steps to ensure adherence to quality standards. It starts with the slitting of steel coils into strips, followed by edge preparation and continuous welding using high-frequency induction or electric resistance welding. The welded pipes then undergo various inspections and tests to verify their quality, strength, and dimensional accuracy.

Manufacturers prioritize quality control to deliver reliable and durable ERW pipes to customers. In addition, adherence to industry standards and certifications, such as ISO 9001, ensures the production of high-quality pipes capable of meeting specific project requirements.

Product detail

Common Applications of ERW Pipes:

ERW pipes find diverse applications across various industries due to their inherent properties and cost-effectiveness. Some common applications include:

Plumbing and water supply systems: ERW pipes are widely used in plumbing installations for conveying water in residential, commercial, and industrial buildings.

Oil and gas pipelines: ERW pipes play a crucial role in transporting oil and gas over long distances, offering reliability and resistance to external forces.

Structural support and construction: ERW pipes are commonly used in the construction industry for structural components, such as columns, beams, and scaffolding.

Agriculture and irrigation: ERW pipes serve as an efficient solution for irrigation systems, ensuring water delivery to agricultural fields.

HVAC systems: ERW pipes are an integral part of heating, ventilation, and air conditioning systems, enabling the flow of air and fluids.

The benefits of using ERW pipes, such as cost-effectiveness, easy installation, and durability, make them a preferred choice for various applications.

Potential Limitations of ERW Pipes:

While ERW pipes offer numerous advantages, they also have some potential limitations that need to be considered. These include:

Corrosion susceptibility: ERW pipes are more prone to corrosion compared to pipes made of certain other materials. To mitigate this, proper coatings and corrosion prevention measures should be applied to protect the pipes when used in corrosive environments.

External damage: ERW pipes may be susceptible to external damage, especially during transportation or installation. Care must be taken to handle and install the pipes correctly to prevent any potential damage that may compromise their integrity.

Limited size range: ERW pipes are typically available in smaller sizes compared to other pipe types. For larger diameter applications, alternative pipe options may need to be explored.

To counter these limitations, it is important to select appropriate coatings, implement proper installation techniques, and consider alternative pipe materials where necessary.

Safety Considerations with ERW Pipes:

Working with ERW pipes requires adherence to specific safety precautions to prevent accidents and ensure the safety of workers. Some key considerations include:

Proper handling: ERW pipes are heavy and can cause injuries if not handled correctly. Lift and move them using appropriate equipment and follow manual handling guidelines to avoid accidents.

Welding safety: When welding ERW pipes, proper safety gear, such as welding helmets, gloves, and protective clothing, should be used to protect against sparks, arc rays, and heat.

Installation and maintenance: Follow industry best practices and guidelines for the proper installation and maintenance of ERW pipes. Regular inspections and maintenance procedures must be carried out to ensure their continued safe operation.

Compliance with safety regulations and guidelines is essential to prevent accidents and ensure the longevity and reliability of ERW pipes in various applications.

Erw pipe manufacturing process

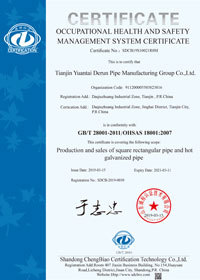

certificate

Comparing ERW Pipes with Other Pipe Types:

When selecting the appropriate pipe for specific applications, comparing ERW pipes with other commonly used pipe types can help determine the most suitable option. Some main types of pipes to consider alongside ERW pipes are:

Seamless pipes: Seamless pipes are manufactured without welding seams, providing a smooth, uninterrupted flow. They are typically used in high-pressure applications where strength and reliability are crucial. ERW pipes offer cost advantages and are suitable for less demanding applications.

LSAW pipes: Longitudinal Submerged Arc Welded (LSAW) pipes are produced using a welding process similar to ERW pipes. However, LSAW pipes have larger diameters and are better suited for heavy-duty applications such as oil and gas transmission and structural construction.

SAW pipes: Submerged Arc Welded (SAW) pipes are commonly used for large-scale projects that require long-distance transmission of fluids or gases. SAW pipes offer higher welding efficiency and excellent mechanical properties but may be more expensive.

Stainless steel pipes: Stainless steel pipes are highly resistant to corrosion and are frequently used in industries where corrosion resistance is critical, such as chemical processing and food production. ERW pipes are cost-effective alternatives suitable for less corrosive environments.

When comparing different pipe types, factors such as application requirements, budget, and environmental considerations should be taken into account to make an informed decision.

Future Trends and Innovations of ERW Pipes:

The manufacturing of ERW pipes continues to evolve, with advancements and innovations shaping the industry's future. Some key trends and innovations include:

Improved welding technology: Advancements in welding techniques, such as high-frequency induction welding and automated systems, enhance the quality and efficiency of ERW pipe production.

Sustainable practices: The industry is increasingly adopting sustainable practices, including using recycled materials and reducing energy consumption during the manufacturing process. These initiatives contribute to reducing the environmental impact of ERW pipe production.

Integration of digital technologies: Digital technologies, such as automation, data analytics, and artificial intelligence, are being integrated into the manufacturing process to improve productivity, quality control, and overall efficiency.

These trends and innovations aim to ensure the continued optimization and growth of the ERW pipe industry, addressing environmental concerns and meeting evolving market demands.

Conclusion:

ERW pipes play a vital role in various industries, offering a cost-effective and dependable solution for diverse applications. Their exceptional strength, durability, and ease of installation make them a preferred choice for plumbing systems, structural support, fluid transportation, and more. While certain limitations must be considered, proper handling, installation, and regular maintenance can mitigate these concerns. By comparing ERW pipes with other pipe types, one can select the most suitable option for specific project requirements. The continuous advancements and innovations in ERW pipe manufacturing ensure a promising future for this essential component of modern infrastructure.