Seamless carbon steel pipe API 5L line tube manufacturer Tianjin Yuantai Derun

- Model

- ytdr-468

Item specifics

- Brand

- Yuantai Derun

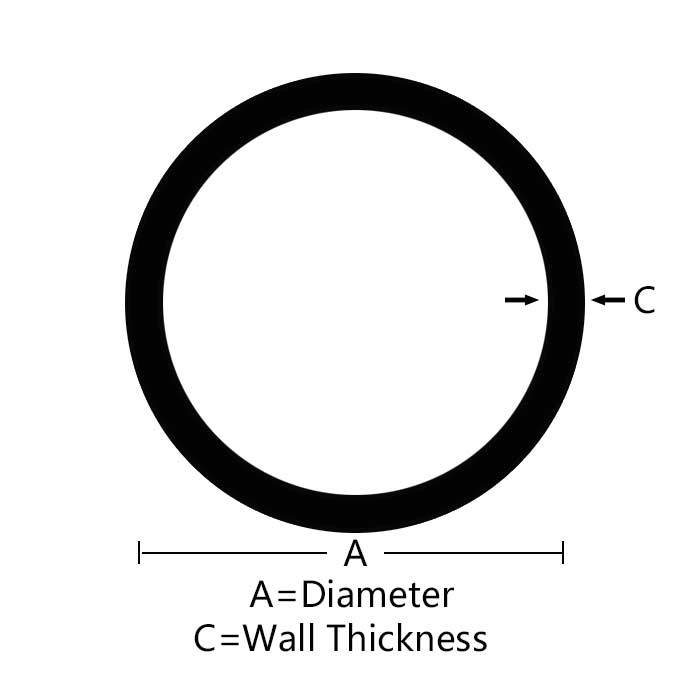

- Thickness

- 0.5-50mm or customized

- OD

- 10.3-820mm

- Length

- 0.5-24M or as client request

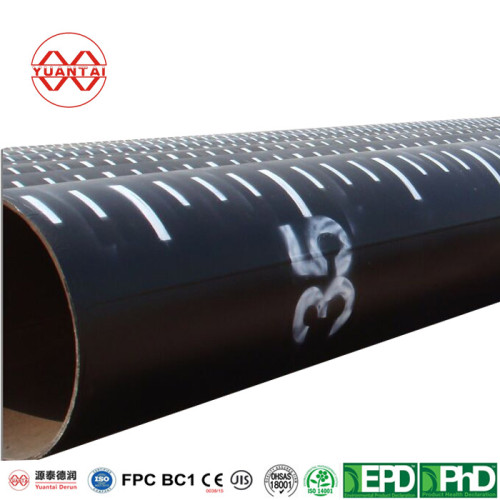

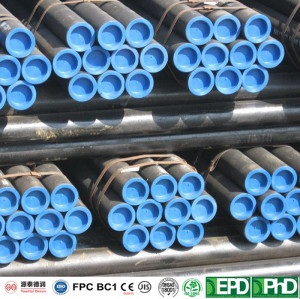

- Surface

- galvanized or painted

- Certificate

- CE,BV,PHD,EPD,ISO,LEED,BC1,JIS,API 5L,ASTM

- Grade

- Gr.A/B/C,S275,S355,S420,S460,X42,X52,X60,X65,X70

- Delivery time

- 7-30 days

- Supply Capacity

- 5 million tons per year

Review

Description

Seamless carbon steel pipe API 5L line tube manufacturer Tianjin Yuantai Derun

Seamless carbon steel pipe overview

Seamless carbon steel pipe is made from steel ingot or solid billet by piercing into a bristle pipe, and then made by hot rolling, cold rolling or cold dialing. Seamless carbon steel pipe has an important position in China's steel pipe industry.

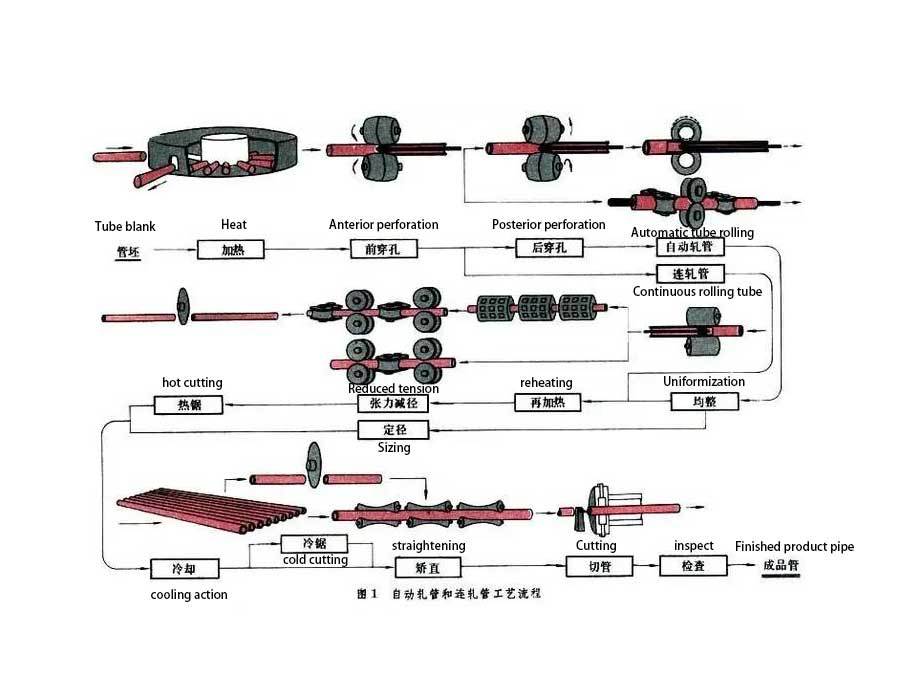

Production process of seamless carbon steel pipe

The raw material of seamless carbon steel pipe is round tube blank, which needs to be cut and processed by a cutting machine into a billet with a length of about 1 meter, and then sent to the furnace for heating through a conveyor belt. The billet is fed into the furnace for heating, with a temperature of approximately 1200 degrees Celsius. The fuel is hydrogen or acetylene. Temperature control in the furnace is a crucial issue. After the round tube billet is discharged from the furnace, it needs to pass through a pressure piercing machine for piercing. The commonly used piercing machine is a conical roller piercing machine, which has high production efficiency, good product quality, large perforation and expansion capacity, and can pierce various steel grades. After perforation, the round tube blank is sequentially rolled, continuously rolled, or extruded by three rollers. After squeezing, the pipe needs to be detached and sized. The sizing machine uses a conical drill bit to rotate at high speed into the steel billet for drilling, forming a steel pipe. The inner diameter of the steel pipe is determined by the outer diameter length of the sizing machine drill bit. After the steel pipe is sized, it enters the cooling tower and is cooled by water spray. After cooling, the steel pipe needs to be straightened. After straightening, the steel pipe is transported by a conveyor belt to a metal inspection machine (or hydraulic test) for internal inspection. If there are cracks, bubbles, and other issues inside the steel pipe, they will be detected. After the quality inspection of steel pipes, strict manual selection is also required. After the quality inspection of the steel pipe, the number, specification, production batch number, etc. are sprayed with paint. And lifted into the warehouse by a crane.

Theoretical weight table for seamless carbon steel pipes

Outer diameter (mm) | Wall thickness (mm) | |||||||||

16mm | 17mm | 18mm | 19mm | 20mm | 22mm | 24mm | 25mm | 26mm | 28mm | |

Theoretical weight (kg/m) | ||||||||||

102mm | 33.93 | 35.64 | 37.29 | 38.89 | 40.44 | 43.40 | 46.17 | 47.47 | 48.72 | 51.09 |

108mm | 36.30 | 38.15 | 39.95 | 41.70 | 43.40 | 46.66 | 49.72 | 51.17 | 52.58 | 55.24 |

114mm | 38.67 | 40.67 | 42.62 | 44.51 | 46.36 | 49.91 | 53.27 | 54.87 | 56.43 | 59.38 |

121mm | 41.43 | 43.60 | 45.72 | 47.79 | 49.82 | 53.71 | 57.41 | 59.19 | 60.91 | 64.22 |

127mm | 43.80 | 46.12 | 48.39 | 50.61 | 52.78 | 56.97 | 60.96 | 62.89 | 64.76 | 68.36 |

133mm | 46.17 | 48.63 | 51.05 | 53.42 | 55.73 | 60.22 | 64.51 | 66.59 | 68.61 | 72.50 |

140mm | 48.93 | 51.57 | 54.16 | 56.70 | 59.19 | 64.02 | 68.66 | 70.90 | 73.10 | 77.34 |

146mm | 51.30 | 54.08 | 56.82 | 59.51 | 62.15 | 67.27 | 72.21 | 74.60 | 76.94 | 81.48 |

152mm | 53.66 | 56.60 | 59.48 | 62.32 | 65.11 | 70.59 | 75.76 | 78.30 | 80.79 | 85.62 |

159mm | 56.43 | 59.53 | 62.59 | 65.60 | 68.56 | 74.33 | 79.90 | 82.62 | 85.28 | 90.46 |

168mm | 59.98 | 63.31 | 66.59 | 69.82 | 73.00 | 79.21 | 85.23 | 88.16 | 91.05 | 96.67 |

180mm | 64.71 | 68.34 | 71.91 | 75.44 | 78.92 | 85.72 | 92.33 | 95.56 | 98.74 | 104.96 |

194mm | 70.24 | 74.21 | 78.13 | 82.00 | 85.28 | 93.32 | 100.62 | 104.19 | 107.72 | 114.63 |

203mm | 73.78 | 77.97 | 82.12 | 86.21 | 90.26 | 98.20 | 105.94 | 109.74 | 113.49 | 120.83 |

219mm | 80.10 | 84.69 | 89.23 | 93.71 | 98.15 | 106.88 | 115.42 | 119.61 | 123.75 | 131.89 |

245mm | 90.36 | 95.59 | 100.77 | 105.90 | 110.98 | 120.99 | 130.80 | 135.64 | 140.42 | 149.84 |

273mm | 101.41 | 107.33 | 113.20 | 119.02 | 124.79 | 136.18 | 147.38 | 152.90 | 158.38 | 169.18 |

Chemical composition of seamless carbon steel pipes

Carbon C: 0.1-0.25%

Silicon Si: 0.5-0.80

Manganese Mn: 0.10-1.40

Sulfur S: allowable content ≤ 0.035%

Phosphorus P: allowable content ≤ 0.035%

Chromium Cr: 0.80-1.10

Molybdenum Mo: 1.25~2.50

Vanadium V: 0.07-1.2

Copper Cu: allowable content ≤ 0.30%

Performance parameter of seamless carbon steel pipes

Seamless carbon steel pipe: commonly used seamless steel pipe material with good toughness and plasticity, mainly used in general mechanical structures.