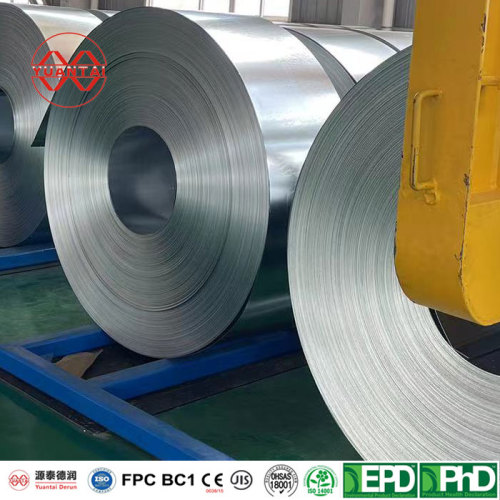

zinc aluminum magnesium strip steel 1010mm * (0.7-3.0mm)

- Model

- ytdr-strip steel

Item specifics

- Width

- 1010mm or customization

- Thickness

- 0.7-3.0mm

- Coating

- Zinc aluminum magnesium coating

Review

Description

zinc aluminum magnesium strip steel

Overview

Zinc aluminum magnesium is an alloy metal mainly used for anti-corrosion treatment of the surface of steel and steel products. Zinc aluminum magnesium coated steel plates are coated steel plates with a certain amount of Al and Mg added to the hot-dip galvanized coating or a certain amount of Mg element added to the hot-dip aluminum zinc coating. They have high corrosion resistance, high edge protection performance, and corrosion resistance is about 10 times higher than ordinary plates and strips. Initially developed and mass-produced by Japan, it was mainly used for brackets. With the increase in production, it also began to cover various industries, including the construction industry, mechanical and electrical industry, highway guardrails, automotive industry, power industry, and daily civilian life.

Application of Zinc Aluminum Magnesium Steel Coil

Zinc aluminum magnesium products are currently mainly used in photothermal and photovoltaic steel structures, as well as in building materials, household appliances, automobiles, and other fields. Yuantai Derun high-strength high zinc zinc aluminum magnesium alloy coated plate is currently targeted for research and development in the photovoltaic support industry in large quantities.

Production process of zinc aluminum magnesium steel coil

Specification parameters

Production specification: 0.4mm~4.5 * 685~1050mm (supports longitudinal cutting and slitting)

Plating thickness: 40-450g/㎡ (double sided)

Surface treatment: passivation, fingerprint resistance, oiling

Varieties include: low-carbon steel: DC51D+ZMDC52D+ZMDC53D+ZM

Structural steel: S250GD+ZM~S550GD+Z

Low alloy high-strength steel: HC260LAD+ZM~HC340LAD+ZM

Dual phase steel: HCT450X+ZM, HCT590X+ZM

Advantages and Applications of Zinc Aluminum Magnesium

1. It has better corrosion resistance, which is several to ten times higher than galvanized sheet within a certain range

2. With low friction coefficient and stable friction characteristics, it is very beneficial for stamping and can reduce the wear of the coating, thereby reducing the burrs and missing lines of the parts.

3. It has good welding performance, as the addition of magnesium can reduce spatter near the weld seam during laser welding and improve welding performance.