EN10219 S355NLH black welded square steel pipe china supplier

- Model

- S355NLH

Item specifics

- Thickness

- 0.5- 60 mm

- OD(Outer diameter)

- 10*10-1200*1200mm

- Certification

- CE,LEED,BV,PHD&EPD,BC1,EN 10210,EN10219,ISO9000

- Surface Treatment

- Black painted or REQUEST

- Tolerance

- as required

- Length

- 0.5-26.5M according to client requirement

- Materials

- S355NLH

- Delivery Time

- 7-30 Days

Review

Description

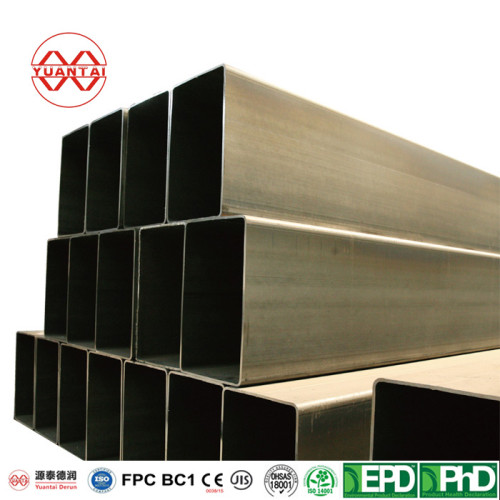

EN10219 S355NLH Black Welded square steel pipe china supplier

EN10219 S355NLH Black Welded Sq Steel Tube is an important metal building material in modern construction engineering. This square tube complies with the European standard EN10219 and uses S355NLH steel grade. EN10219 S355NLH Black Welded Sq Steel Tubing has excellent load-bearing performance, seismic performance, and welding performance, becoming a reliable raw material option for many major projects. The EN10219 S355NLH Black Welded Sq Tube produced by Yuantai Derun has the advantages of tight and sturdy welds, complete size and high precision, excellent performance, and affordable price. Send Your Inquiry Now!

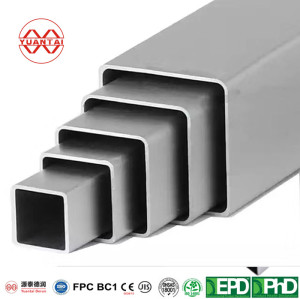

Square Tubing Sizes

At Yuantai Derun, we have the most comprehensive range of Square Tubing Sizes and accept customization of sq tubing outer diameter, wall thickness, length, and R-angle. Send the required size immediately.

|

Square Steel Tubing Sizes

|

|||

|

Type

|

Outer Diameter(mm)

|

Wall Thickness(mm)

|

Length(M)

|

|

Low Carbon Steel Tube

|

10*10-1200*1200

|

0.5-60

|

0.5-26.5

|

Square Steel Tube Manufacturing Process

At Yuantai Derun,Square Steel Tube Manufacturing Process mainly have those types:

1.DFT(direct forming technique)

2.LSAW+Round Tube To Square Tube

3.Seamless+Round SMLS Tube To Square Tube

Square Steel Tube Customization Options

At Yuantai Derun, you can flexibly customize the following options for square steel pipes.

1. shape

Yuantai Derun can produce Square Steel Tube in different shapes. Common Square Steel Tube shapes include right-angled Square Steel Tube, arc-angled Square Steel Tube, etc.

2. heat treatment

Yuantai Derun can conduct normalizing, quenching, tempering, annealing and other heat treatments on your EN10219 S355NLH Black Welded Sq Steel Tube to better remove the internal stress existing around the weld seam of the EN10219 S355NLH Black Welded Sq Steel Tube and greatly reduce the risk of cracking of the Sq Steel Tube.

3. size customization

You can flexibly customize the length, outer diameter, wall thickness, etc. of the EN10219 S355NLH Black Welded Sq Steel Tube, which can better suit your project needs.

Square Tube Coating

At Yuantai Derun,Sq Tube Coating mainly have those types:

1. oiling

Oiling can temporarily protect your EN10219 S355NLH Black Welded Sq Steel Tube from rust and corrosion for a short time.

2. hot dipped galvanizing

Hot-dip galvanizing can better protect your EN10219 S355NLH Black Welded Sq Steel Tube for a long time, which is currently recognized as a globally recognized anti-corrosion treatment method.

3. painted

Painting can protect EN10219 S355NLH Black Welded Sq Steel Tube from external corrosion in a short period of time, which is a better surface treatment method than oiling.

Chemical Composition

|

Carbon ≤ 0.18%

|

silicon ≤ 0.50%

|

manganese ≤ 0.9-1.65%

|

phosphorus ≤ 0.030%

|

|

sulfur ≤ 0.025%

|

niobium ≤ 0.05%

|

vanadium ≤ 0.12%

|

Aluminum ≥ 0.020%

|

|

titanium ≤ 0.03%

|

chromium ≤ 0.30%

|

nickel ≤ 0.5%

|

molybdenum ≤ 0.10%

|

|

copper ≤ 0.35%

|

nitrogen ≤ 0.015%

|

Mechanical Properties

|

Yield Strength

|

Tensile Strength

|

Elongation |

|||

|

Wall thickness ≤ 16mm

|

16mm<wall thickness ≤ 40mm

|

Wall thickness ≤ 16mm

|

16mm<wall thickness ≤ 40mm | Wall thickness ≤ 16mm

|

16mm<wall thickness ≤ 40mm

|

|

≥ 355MPa

|

≥ 345MPa

|

≥ 470-630MPa

|

≥ 470-630MPa | ≥ 22% |

≥ 22%

|

Benefits

EN10219 S355NLH Black Welded Sq Steel Tube produced by Yuantai Derun has those advantages:

1.Free Sample

You can got free samples from our factory,the length is not more than 20 CM,you only need to pay a shipping fee. Get Free Sample Now!

2.High Quality

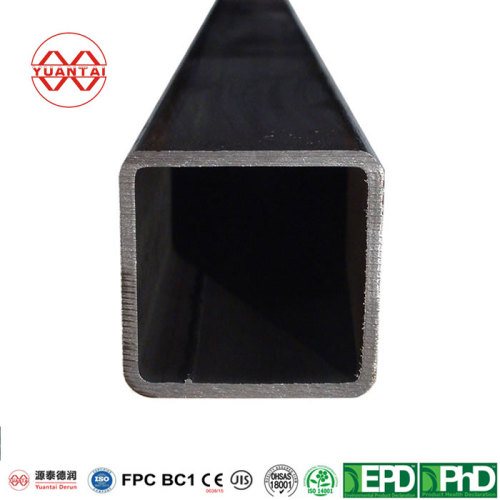

EN10219 S355NLH Black Welded Sq Steel Tube produced by Yuantai Derun has undergone strict inspection. From raw materials to finished products, every process is traceable to ensure that the product meets 100% customer requirements before leaving the factory. EN10219 S355NLH Black Welded Sq Steel Tube produced by Yuantai Derun has product advantages such as tight weld seam, smooth and cleaning tube body, flat tube end, and high size accuracy.

3.Large Capacity

Yuantai Derun has the most complete production line, which can quickly produce and customize EN10219 S355NLH Black Welded Sq Steel Tube of various specifications, with an annual production capacity of 5 million tons, which can meet customers 'needs for rapid delivery.

Applications

EN10219 S355NLH Black Welded Sq Steel Tube produced by Yuantai Derun have excellent quality, strength and weldability, suitable for use in applications requiring strength and aesthetics, mainly used for:

1. Building structural components

2. Mechanical structure manufacturing

3. Heavy steel structure

4. Bridge structure

5. Powerhouse structure

6. Storage building

7. Prefabricated buildings

8. Ship construction

10. Mine support

11. Tunnel support structure

12. Dam structure

FAQS

Can Yuantai Derun produce 3/4 inch mild steel sq tube?

Yes,Yuantai Derun Can Produce 3/4 inch mild steel sq tubes.

What are the common dimensions and sizes of EN10219 S355NLH Black Welded sq steel tubing?

1. 20* 20*1.5mm

2. 25*25*1 .5mm

3. 30*30*1. 5mm

4. 40*40*1.5mm

5. 50*50*1. 5mm

6. 60*60*2.0mm

7. 80*80*2.0mm

8. 100*100*2.0mm

9. 120*120*2.0mm

10. 150*150*2.0mm

How are sq steel tubes manufactured in metal pipe factories?

The production process of sq steel tubes mainly includes the selection of raw materials, flattening of steel plates, welding, straightening, cutting, straightening, and finished product inspection.

1. Selection of raw materials: The raw materials for square steel tubings are generally high-quality steel plates. According to different purposes and requirements, suitable materials are selected, such as ordinary carbon structural steel, low alloy high-strength steel, etc.

2. The selected steel plate needs to be flattened and repaired with mechanical equipment to ensure that the flatness of the steel plate meets the requirements.

3. Welding: The flattened steel plates are connected through a welding process to form a square tubular structure. Common welding methods include electric welding, gas welding, laser welding, etc. Choose the appropriate method according to different needs.

4. After straightening and welding, the sq steel tube needs to be straightened and stretched and compressed by mechanical equipment to meet the specified straightness requirements.

5. The sq steel tubing after cutting and straightening needs to be cut according to customer requirements to obtain the required length of product.

6. After straightening and cutting, the sq steel tube may undergo certain deformation, and straightening treatment is needed to restore it to the specified shape.

7. Finished product inspection: Conduct quality inspection on the sq steel tubes produced, including appearance inspection, dimensional measurement, mechanical performance testing, etc., to ensure that the products comply with relevant standard requirements.

What is Sq Tube Meaning?

The Sq Tube Means that square tube.