Hollow Structural Sections (HSS)

- Model

- hss tube

Item specifics

- Thickness

- 0.5- 60 mm

- Certification

- CE,LEED,BV,PHD&EPD,BC1,EN 10210,EN10219,ISO9000

- Tolerance

- as required

- Length

- 0.5-26.5M according to client requirement

- Standards

- ASTM A500/A501,EN10219,EN10210

- Materials

- Gr.A/Gr.B/Gr.C,S235,S275,S355,S420,S460,A36,A53

- Delivery Time

- 7-30 Days

Review

Description

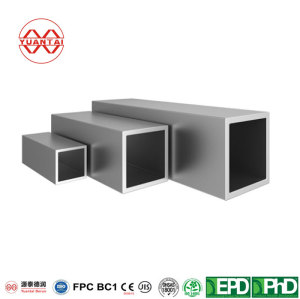

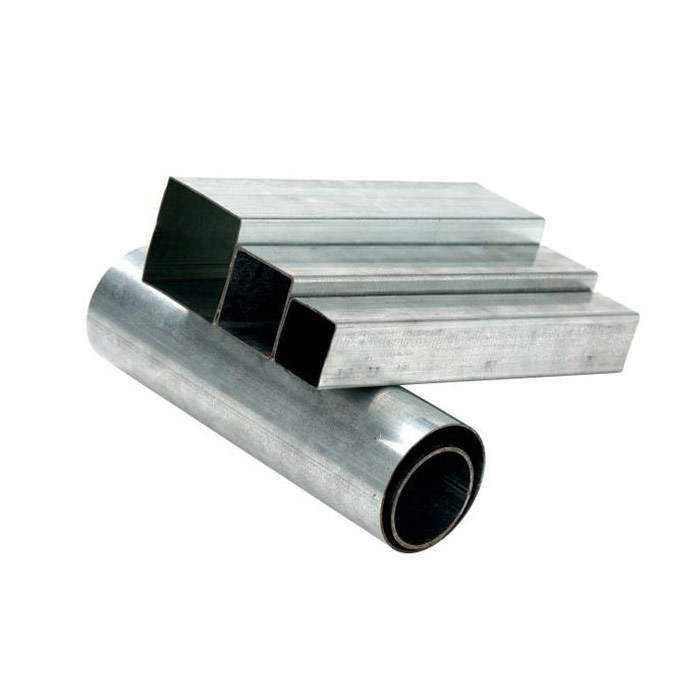

Hollow Structural Sections (HSS)

Hollow Structural Sections (HSS) is a common metal building material. Yuantai Derun is the largest Hollow Structural Sections (HSS) factory in China, which produces Hollow Structural Sections (HSS) with obvious advantages such as high strength and stable performance. Hollow Structural Sections (HSS) are widely used in architectural and mechanical applications. Send your request now.

Type Of Hollow Structural Section(HSS)

At Yuantai Derun, in the sale of hollow structural section type there are mainly the following kinds, each kind of hollow structural section has different performance characteristics, hollow structural section price is not the same, if you need to have the price of hollow structural section, you can immediately contact the customer manager.

Black-Hollow-Structural-Section(HSS)

Without Any Coating

Pre Galvanized Hollow Structural Section HSS

Made Of Galvanized Coils

Zinc Aluminum Magnesium Coating Hollow Structural Section

Made Of Zinc Aluminum Magnesium Steel Coils

Hot Dip Galvanized Hollow Structural Section

Hot Dip Galvanizing

More Hollow Structural Sections (HSS) Standard And Grade You Can Choose

You can have more Hollow Structural Section (HSS) standards to choose from at Yuantai Derun, the details of the standards are listed below:

|

Name

|

American Standard (US)

|

European Standard

|

Canadian Standard

|

Japanese and Korean Standard | Australian Standard (AS) |

|

HSS Tube Square

|

ASTM A500/501,ASTM A1085,ASTM A53,ASTM A106,ASTM A513,etc

|

EN 10219,EN 10210,etc.

|

CSA G40.20/G40.21,etc

|

JIS G3466,etc | AS/NZS 1163 |

|

HSS Tube Rectangular

|

|||||

|

HSS Tube Round

|

|

Name

|

Steel Grade

|

||

|

hollow structural steel sections

|

Gr.A/B/C,S235/275/355/420/460,A36,SS400,Q195/235/355,STKR400/490,300W/350W,etc.

|

||

More standards and grades Yuantai Derun can produce,please contact our sales manager.

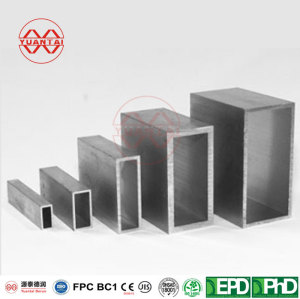

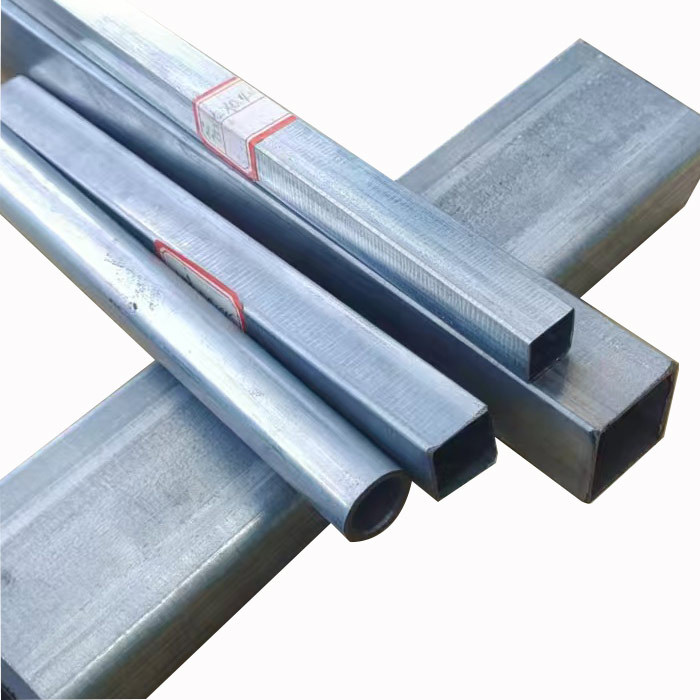

Complete Hollow Structural Section Dimensions For You

At Yuantai Derun,We have the most complete coverage of hollow structural section sizes in China, whether it is square hollow structural section, rectangular hollow structural section, or circular hollow structural section. Below is the size chart of hollow structural section, in addition, you can also customize the outer diameter, wall thickness, and length of hollow structural section flexibly. Send your size request today.

|

Shape

|

Outer Diameter(mm)

|

Wall Thickness(mm)

|

Length(M)

|

|

square hollow structural section

|

10*10-1200*1200

|

0.5-60

|

0.5-26.5

|

|

rectangular hollow structural section

|

10*15-800*1200

|

0.5-60

|

0.5-26.5

|

|

circular hollow structural section

|

10.3-3620

|

0.5-60

|

0.5-24

|

HSS Hollow Structural Sections Properties

HSS Hollow Structural Sections Properties include:

1. Tighter welding seam

The production of each HSS hollow structure section adopts the more advanced welding equipment and welding raw materials in China, which realizes a high degree of fusion between the base material and the weld seam, and reduces the risk of cracking during use.

2. High dimensional accuracy

Hollow Structural Sections (HSS) produced by Yuantai Derun have high dimensional accuracy, and some high-precision customized hollow sections can also be produced.

3. Stable performance

Hollow Structural Sections (HSS) produced by Yuantai Derun have stable performance, which can greatly reduce the subsequent maintenance costs.

Hollow Structural Section Making

Hollow Structural Section Making Process Of Yuantai Derun:

1. ERW HSS Tube Making Process >>More Detail

2. LSAW HSS Tube Making Process>>More Detail

3. SSAW HSS Tube Making Process>>More Detail

4. Seamless HSS Tube Making Process>>More Detail

Application

Hollow Structural Sections (HSS) produced by Yuantai Derun are used in a wide range of applications. Common application scenarios are as follows:

1.Construction field

Assembly building, steel structure plant, greenhouse structure, glass curtain wall structure, stadium, high-grade villa, high-speed railway station, airport, train station, high-speed fence, mine tunnel structure, bridge and so on.

2.Machinery Manufacturing

Agricultural machinery manufacturing, gantry crane manufacturing, shipbuilding, container manufacturing, truck manufacturing, car manufacturing, power equipment manufacturing, fitness equipment manufacturing, chemical machinery manufacturing and so on.