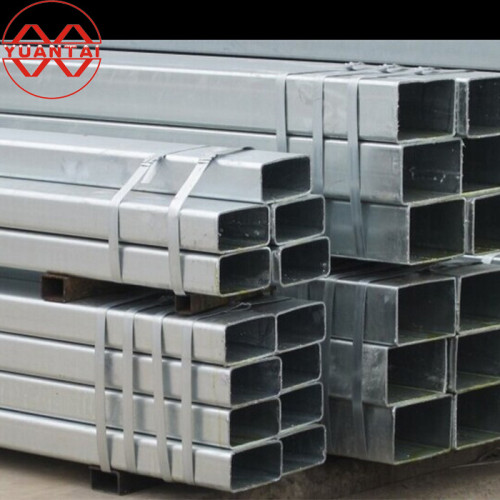

Galvanized Square Pipe Hot Rolled Hollow Section 1.5 inch galvanized pipe price

- Model

- galvanized steel tube

Item specifics

- Thickness

- 0.5- 60 mm

- OD(Outer diameter)

- 10*10-1200*1200mm 10*15-800*1200mm 10.3-3620mm

- Certification

- CE,LEED,BV,PHD&EPD,DNV,BC1,EN10210/10219,ISO9000

- Tolerance

- as required

- Length

- 0.5-26.5M according to client requirement

- Standards

- ASTM A500/A501,EN10219/10210,SS400,etc

- Materials

- Gr.A/B/C,S235/275/355/420/460,A36/A53/572/106,etc

- Delivery Time

- 7-30 Days

Review

Description

Galvanized Steel Tubing

Normally, galvanized steel tubing is the general term for galvanized strip steel tube and hot-dip galvanized steel tube. Galvanized steel tubes are made from galvanized steel coils through processes such as roll forming, high-frequency welding, sizing, cutting, and testing. Hot dip galvanized steel tubing is made by hot-dip galvanizing black steel tubes.

Galvanized steel tubings are widely used due to their excellent anti-corrosion, welding, and mechanical properties.

Benefits of Galvanized Steel Tubing

Galvanized steel tubing offers several advantages over other types of steel tubings.

1. excellent corrosion resistance

Firstly, the zinc coating provides excellent corrosion resistance, allowing the tubing to withstand harsh environmental conditions, including exposure to moisture and corrosive chemicals.

2. good welding

Additionally, galvanized steel tubing has good welding. Easy for construction workers to install, connect, weld, and perform other operations.

3. perfect mechanical properties

Thirdly, galvanized square tubes have good physical and mechanical properties, such as good yield strength and tensile strength, excellent impact performance, etc. It is a good raw material for building structures and mechanical structures.

Complete Galvanized Steel Tubing Sizes For You

At Yuantai Derun, the specifications of galvanized steel pipes are particularly complete.

The following is a detailed list of specifications for various galvanized steel pipes. If you need more information on the dimensions of galvanized steel pipes, please contact us.

|

Shape

|

Outer Diameter(mm)

|

Wall Thickness(mm)

|

Length(M)

|

|

Galvanized Steel Square Tubing

|

10*10-1200*1200

|

0.5-60

|

0.5-26.5

|

|

Galvanized Rectangular Steel Tubing

|

10*15-800*1200

|

0.5-60

|

0.5-26.5

|

|

Galvanized Round Steel Tubing

|

10.3-3620

|

0.5-60

|

0.5-24

|

Galvanized Steel Tubing Specification Table

Free Galvanized Steel Tubing Samples For You

In order to better verify the quality of products, users of some projects need to collect samples from suppliers in advance. For the convenience of customers, Yuantai Derun has launched a free activity for galvanized steel tubing samples. The content is as follows:

1. We can make samples for free for anything within 20 centimeters in length.

2. The samples are free, you only need to pay for one shipping fee.

How To Know Galvanized Steel Tubing Weight?

At Yuantai Derun,We have 2 ways to know galvanized steel tubing weight.

1. Weigh

Weighing is a quick way to determine the weight of galvanized pipes. This calculated weight is fast and accurate.

2. Theoretical Calculations

Theoretical calculations are common and are done using the theoretical formula for galvanized steel tubing. This method usually only produces a rough result, and there is usually some discrepancy with the actual weight. if you want to know your galvanized steel tubing weight,please contact our sales manager.

Appendix: Theoretical Weight Table For Galvanized Round Steel Tubing (Executed According To Gb/T3091-2001 Standard)

|

specifications

|

O.D.(mm) | THK(mm) | Minimum wall thickness(mm) | Welded pipe (6-meter customized size) | Galvanized pipe (6 meter customized size) |

Unit price/meter

|

|||

|

Nominal inner diameter

|

inch

|

Meter weight (kg) | Weight of each piece (kg) | Meter weight (kg) |

Weight of each piece (kg)

|

||||

|

DIN15

|

0.5

|

21.3 | 2.8 | 2.45 | 1.28 | 7.68 | 1.357 |

8.14

|

7.3

|

DIN20 | 0.75 | 26.9 | 2.8 | 2.45 | 1.66 | 9.96 | 1.76 | 10.56 | 9.5 |

|

DIN25

|

1

|

33.7 | 3.2 | 2.8 | 2.41 | 14.46 | 2.554 |

15.32

|

13.8

|

DIN32 | 1.25 | 42.4 | 3.5 | 3.06 | 3.36 | 20.16 | 3.56 | 21.36 | 19.2 |

DIN40 | 1.5 | 48.3 | 3.5 | 3.06 | 3.87 | 23.22 | 4.1 | 24.6 | 22.1 |

DIN50 | 2 | 60.3 | 3.8 | 3.325 | 5.29 | 31.74 | 5.607 | 33.64 | 30.3 |

DIN65 | 2.5 | 76.1 | 4 | 3.5 | 7.11 | 42.66 | 7.536 | 45.21 | 40.7 |

DIN80 | 3 | 88.9 | 4 | 8.38 | 50.28 | 8.88 | 53.28 | 48.0 | |

DIN100 | 4 | 114.3 | 4 | 10.88 | 65.38 | 11.53 | 69.18 | 62.3 | |

DIN125 | 5 | 140 | 4.5 | 15.04 | 90.24 | 15.924 | 98.65 | 88.8 | |

Galvanized Steel Tubing Application

1. The most common application of galvanized steel tubings in the construction industry is as structural materials. It can be used to manufacture support structures in large-scale projects such as bridges, tunnels, and railway tracks. Galvanized steel tubing can also be used as columns or beams in buildings.

2. Environmental protection equipment: Galvanized steel tubings are often used to manufacture environmental protection equipment such as exhaust gas treatment equipment and flue gas emission systems.

3. Water supply and drainage, petrochemicals, natural gas:

4. Generally used for making fences, barriers, guardrails, and balcony guardrails. Widely used in municipal engineering, roads, factories, schools, development zones, gardens, and squares

FAQs

Q1: What is the difference between galvanized and stainless steel tubing?

1. Essential differences

Galvanized pipes are called carbon steel, and their surface is coated with zinc to meet daily usage needs. Stainless steel pipes, on the other hand, belong to alloy steel and have corrosion resistance. Do not perform other treatments.

2. Price difference

Galvanized pipes are cheaper than stainless steel pipes, and having a bright surface on the galvanized pipe is sufficient. There is no way to achieve the shine of stainless steel pipes, and the effect will be slightly worse.

3. Performance differences

Galvanized pipes cannot be further processed, and the carbon content inside will be higher, containing better hardness and brittleness. Stainless pipes also have stronger performance and can be further processed.

Q2: Can galvanized steel tubing be used for outdoor applications?

Galvanized steel pipe is a steel pipe material suitable for outdoor use

It can withstand strong weather conditions such as sunlight and rain, and has good durability and applicability.

Q3: How can I ensure the quality of galvanized steel tubing?

In order to ensure the excellent quality of galvanized steel pipes, Yuantai Derun Steel Pipe Group mainly controls them from the following aspects. The first is raw materials, and high-quality raw materials are the first level to ensure the quality of galvanized steel pipes. We use steel plates or coils from large factories as raw materials.

The second is the molding process. Yuantai Derun adopts the most advanced technology in China, and every production step is strictly controlled.

The third is product testing. Yuantai Derun has a national level CNAS laboratory, and the mechanical properties, chemical composition, hardness, and metallographic structure of steel pipes are strictly tested according to customer standards.

Q4: Can galvanized steel tubing be welded?

Yes,galvanized steel pipes can be welded.

Q5: Are there any environmental concerns with galvanizing steel Tubing?

Galvanized steel tubings are relatively environmentally friendly. When using galvanized steel tubings, they will not cause any harm to human health and the environment. In fact, galvanized steel tubings are just a category of decoration pipes. From the name, we can also see that the surface of this type of pipe is coated with a layer of zinc, and zinc itself is a material without any harmful substances.

Nowadays, galvanized steel tubing are commonly used in the construction industry. When building buildings, most families choose to use this material.