iron square pipe |factory direct supply| hot dip galvanized |SHS| S460MLH EN10219

- Model

- S460MLH Tubes

Item specifics

- Thickness

- 0.5- 60 mm

- OD(Outer diameter)

- 10*10-1200*1200mm

- Certification

- CE,LEED,BV,PHD&EPD,BC1,EN 10210,EN10219,ISO9000

- Tolerance

- as required

- Length

- 0.5-24M according to client requirement

- Materials

- S460MLH

- Delivery Time

- 7-30 Days

Review

Description

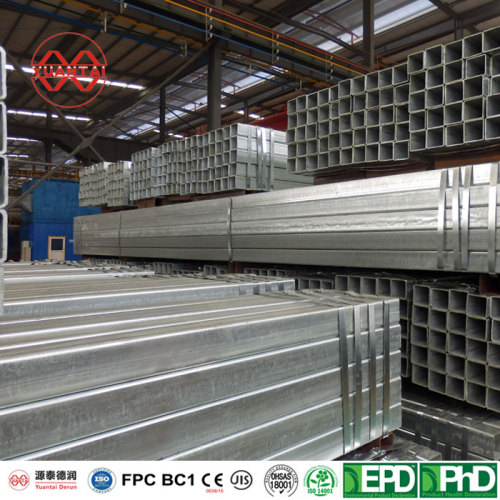

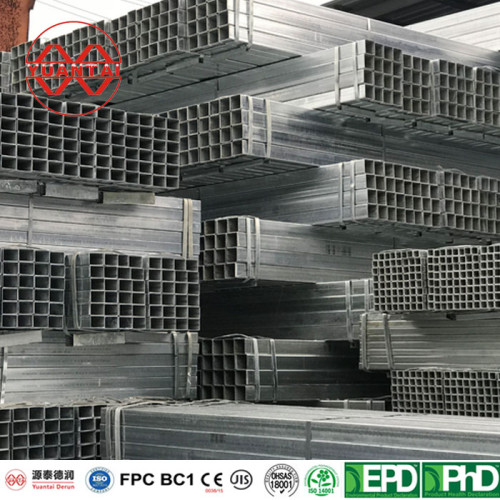

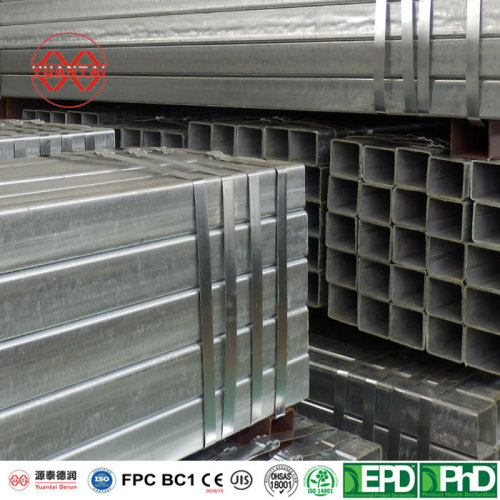

Iron Square Pipe |Factory Direct Supply| Hot Dip Galvanized |Shs| S460mlh En10219

Iron square pipes, also known as square hollow sections (SHS), are a popular choice in various construction and industrial applications. They are versatile, durable, and offer exceptional strength. Iron square pipes have become an integral component of modern construction and engineering projects. Their distinct shape allows for efficient distribution of weight while maintaining structural integrity. Yuantai Derun is the largest big square iron pipe in China.

EN10219 S460MLH Iron Square Pipe Chemical Composition

|

Carbon

|

Silicon

|

Manganese

|

Phosphorus | Sulfur | Niobium | Vanadium | Aluminum | Titanium | Nickel | Molybdenum | Nitrogen |

|

≤ 0.16%

|

≤ 0.60%

|

≤ 1.70%

|

≤ 0.030% | 0.025% | 0.05% | ≤ 0.12% | 0.020% | ≤ 0.05% | ≤ 0.3% | ≤ 0.20% | ≤ 0.025% |

EN10219 S460MLH Iron Square Pipe Mechanical Properties

|

Wall Thickness

|

Yield Strength

|

Tensile Strength

|

Elongation

|

|

≤ 16mm

|

≥ 460MPa

|

≥ 530-720MPa

|

≥ 17%

|

|

16mm < wall thickness ≤ 40mm

|

≥ 440MPa

|

≥ 530-720MPa

|

≥ 17%

|

|

Test Temperature

|

Minimum impact energy KV

|

|

-50 °C

|

27J

|

-20 °C | - |

Common Uses Of Iron Square Pipes

Iron square pipes find extensive use in various industries and applications. They are commonly utilized in construction projects, such as building frames, support structures, and infrastructure developments. Additionally, they are employed in the manufacturing of automotive parts, machinery, and agricultural equipment.

FAQS

Can iron square pipes be used for underground applications?

Iron square pipes are not typically recommended for underground applications due to their susceptibility to corrosion. It is advisable to consider alternative materials such as PVC or HDPE for such purposes.

What precautions should be taken when handling iron square pipes?

When handling iron square pipes, proper safety equipment should be used, including gloves and eyewear. Additionally, it is important to ensure secure lifting and handling techniques to prevent accidents and injuries.

Are iron square pipes resistant to weathering?

Iron square pipes are susceptible to weathering and corrosion, especially when exposed to moisture or harsh environmental conditions. To enhance their longevity, it is advisable to apply protective coatings or galvanization.