hot dip galvanized groove steel pipe

- Model

- hot dip galvanized grooved steel pipe

Item specifics

- Thickness

- 0.5- 16 mm

- OD(outer diameter)

- 10.3mm-609mm

- Supply capacity

- Annual output of 1 million tons

- Certification

- CE,LEED,BV,PHD&EPD,BC1,EN10210/10219,ISO

- Tolerance

- as required

- Length

- 0.5-24M according to client requirement

- Standards

- ASTM A53 , ASTM A795

- Materials

- Gr.A,Gr.B,Gr.C,S275J0H,S355JR,S355J0H,S355J2H,A36,

- Packaging

- Customers't Requirement

- Delivery Time

- 7-30 Days

Review

Description

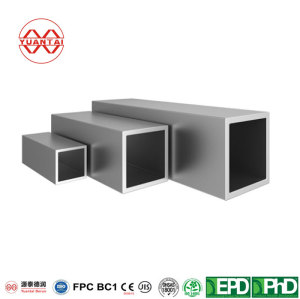

Grooved Galvanized Steel Pipe China Factory Yuantai Derun Group

Groove End Pipe Detail:

|

Name

|

Size

|

Wall Thickness

|

Length

|

|

ERW Pipe

|

φ:10.3-609mm

|

0.5-16mm

|

0.5-24M

|

|

Spiral welded pipe

|

φ:219-3620mm

|

1.5-30mm

|

0.5-24M

|

|

oil casting steel pipe

|

φ:200-2020mm

|

5-28mm

|

0.5-24M

|

Pipe Ends Finished:

Rolling groove end, slotting end. This end can be used to connect slotted accessories such as slotted clamps, slotted elbows, and tees.

Mechanical Properties:

Hydrostatic Test: 5000kPa (725psi)

Max. System Working Pressure: 2068kPa (300psi)

Grooved Galvanized Steel Pipe Specifications and Zinc Coating Detail:

|

Name

|

Pre Galvanized Groove End Pipe

|

Hot Dip Galvanized Groove Steel Pipes

|

|

O.D.(φ)

|

1/2''-8'' (round tubing)

|

1''-18'' (round tubing)

|

|

W.T.

|

1.3-10mm

|

5-30mm

|

|

Length

|

0.5-24 or customized

|

0.5-24M or customized

|

Zinc Coating | 30-120g/m2 | 220-480g/m2 |

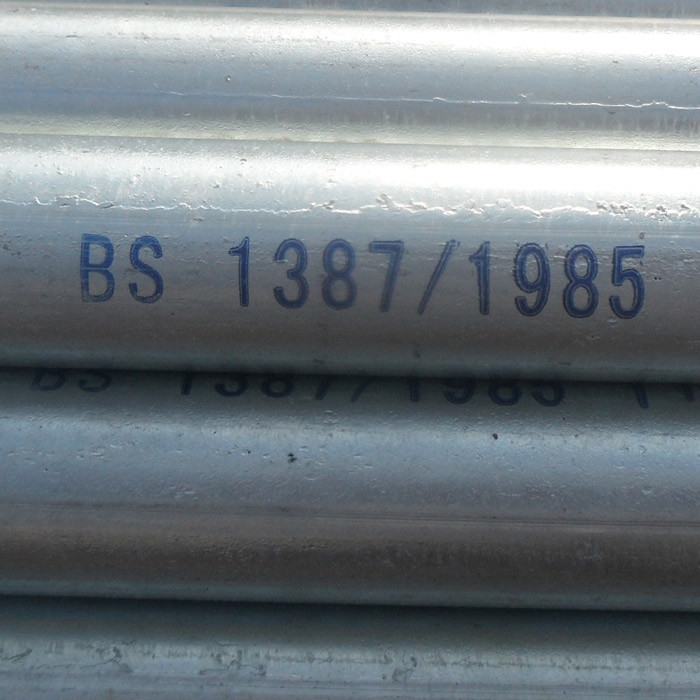

Standard | EN39, ASTM A53, BS1387-85, GB/T3091-08, JIS-G3444, ISO65, BS1139, AS 1074, AS 2419 & AS 4118,etc | |

Packing | In bundles, packed in woven bag; in loose; or request. | |

Delivery Time | about 3 -40 days | |

Hot Dip Galvanized Grooved Steel Pipe Advantages And Features

The pressure groove hot dipped galvanised steel pipe produced by Yuantai Derun is corrosion-resistant, with smooth pipe surface, high internal and external wall finish, low fluid resistance, no joint pipe, the raw materials are from the guaranteed big factory raw materials, 100% conform to the international standard, good hygienic performance, OEM/OBM/ODM is acceptable, welcome to consult and order for the steel pipe sellers all over the world.

Corrosion Resistance

Yuantaiderun galvanized carbon steel pipe grooved ends have good corrosion resistance.

Pipe Surface Is Smooth

The surface of the hot dip galvanized grooved steel pipe shall be smooth without burrs.

No Joint Pipe

There is no joint pipe in the finished galvanized grooved end steel pipe

Raw Materials Are Guaranteed

Yuantai Derun raw meterial are all from large factory direct supply,good quality are guaranteed

Each steel pipe 100% complies with international standards

Each steel pipe is inspected layer by layer

OEM&ODM&OBM

Yuantai Derun accepts hot dip galvanized grooved steel pipe OEM,ODM,OBM

Large Pipe Stock

Yuantai Derun has large groove pipe stock

Fully Qualified

Yuantai Derun has fully qualified,such as BS 1387,a795 steel pipe grooved ends,etc.

Groove Pipes Without Galvanized

This is un-galvanised groove pipe and the quality is great.

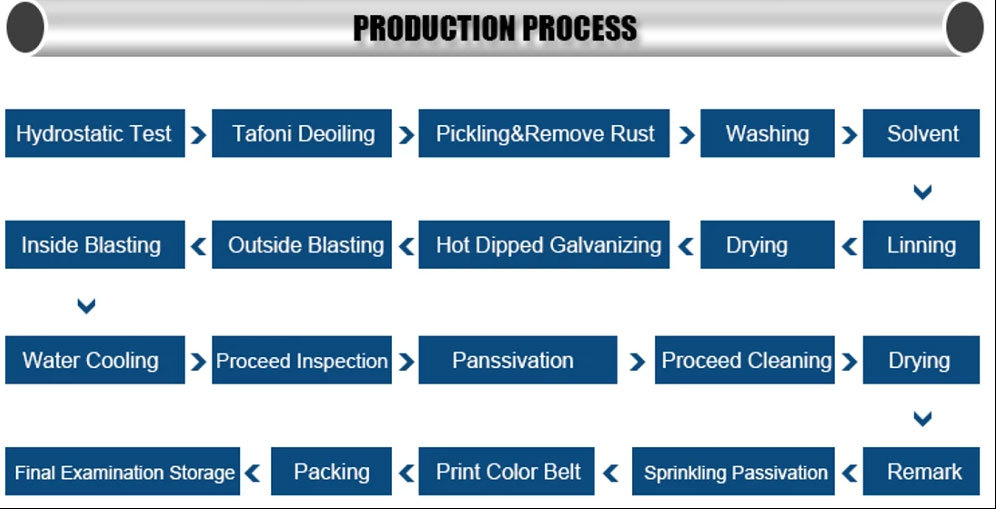

Pipe Making Process:

Hot Dip Galvanized Groove Steel Pipe Making Process

Grooved Black Carbon Steel Tube>Hydrostatic Test>Tafoni Deoiling>Pickling&Remove Rust>Washing>Solvent>Linning>Drying>Hot Dipped Galvanizing>Outside Blasting>Inside Blasting>Water Cooling>Proceed Inspection>Panssivation>Proceed Cleaning>Drying>Remark>Sprinkling Passivation>Print Color Belt>Packing>Final Examination Storage

Pre Galvanized Groove Steel Pipe Manufacturing Process

GI steel coil> uncoiling> Shear Butt Welding>Cold Forming>High Frequency Welding>Sizing>Cutting>Groove>Storage

Strict Product Inspection

Each steel pipe must pass the inspection layer by layer. Only the products that pass the inspection can leave the factory. Never let an unqualified product flow into the market,Yuantai Derun has a CNAS certified testing center,so Yuantai Derun is one of good a795 steel pipe grooved ends suppliers in China.Look,our pipe testing center have this pipe test like this picture below.

Use

Galvanized groove steel pipes are widely used in industries such as natural gas transportation, oil transportation, water supply and drainage, and mining.

Underground Gas Pumping

Underground positive and negative pressure ventilation

Water supply and water drainage

Coal mine underground slurry spraying

Firefighting piping

Electrical piping

mechanical piping

oil and gas pipeline

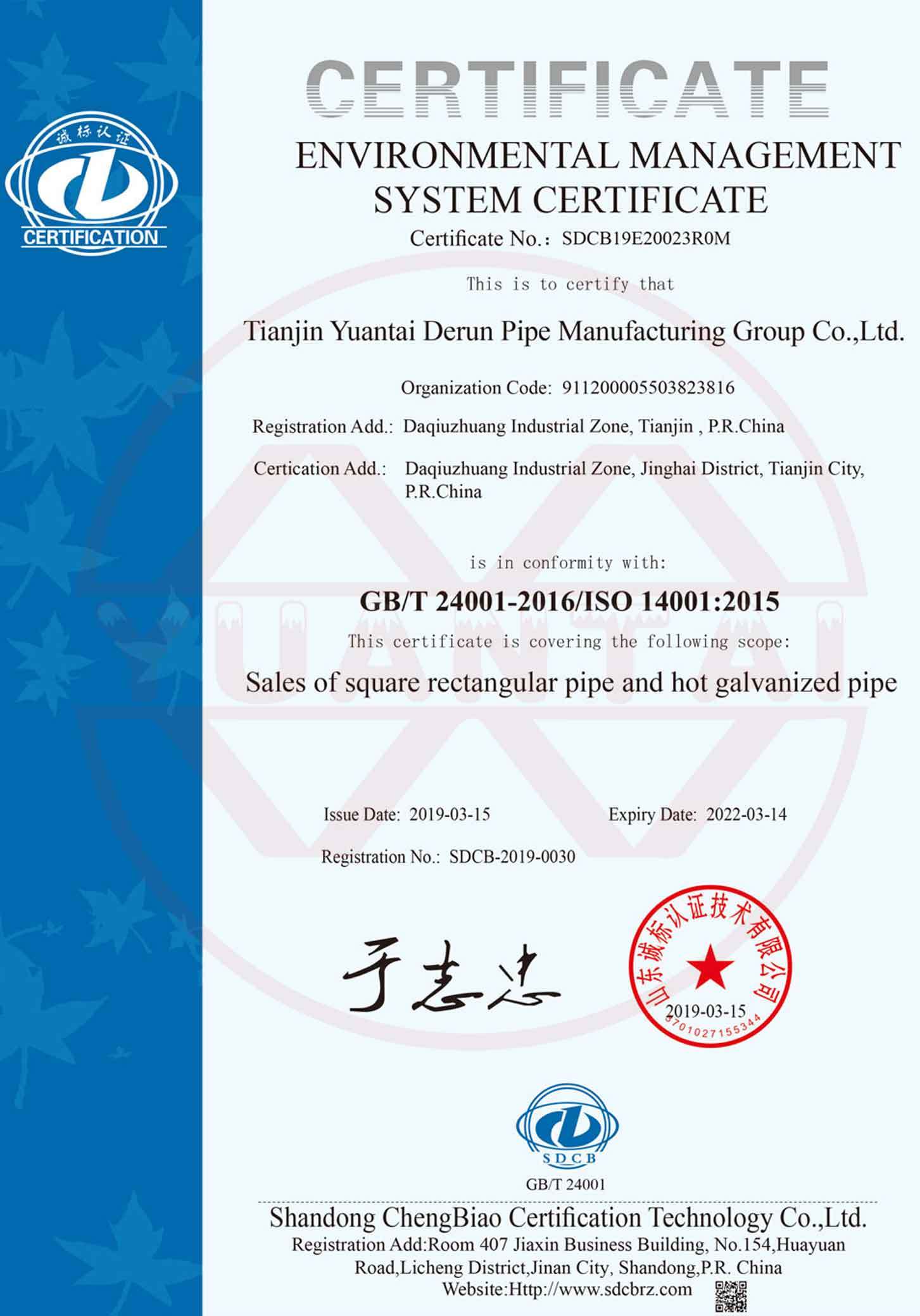

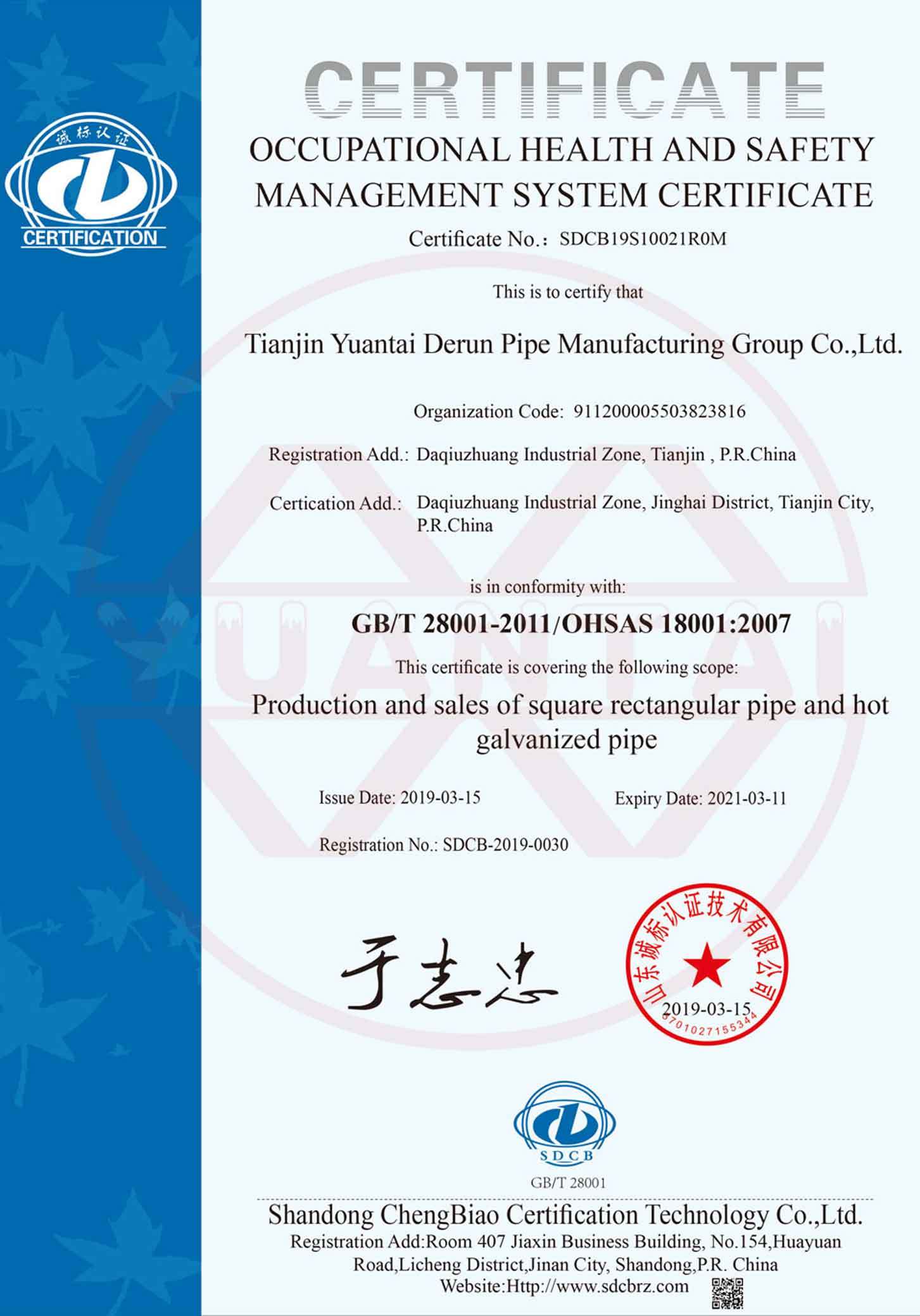

Certificate

Yuantai Derun can produce groove end steel pipe ,it meets AS 1074 for general-purpose steel pipes, AS 2419 for fire hydrants, AS 4118 for automatic sprinkler systems, AS 4792 for coating quality 300g/SQM, AS 4118 and AS 2419 for applications, and UL certification.Yuantai Derun is certified by iso9001,iso18001,iso45001,BV,etc,Yuantai Derun is one of good a795 steel pipe grooved ends factories

ISO9001

Production of Hollow Section Tubes & Hot-dipGalvanized Tubes, Sales& Service of Metal Materials(except the scope of legal mandatory requirements)

BV

This certficate is issued to attest that Bureau Vveritas Marine & Ofishore has perormed, at the above company's request and in compliance withthe requirements of NR320,a satisfactory assessment of the manudacturing facilities and associated quality procedures related to the ranrge of therecogniition.

ISO14001(GB/T 24001)

ENVIRONMENTAL MANAGEMENT SYSTEM CERTIFICATE

OHSAS 18001(GB/T28001-2011)

OCCUPATIONAL HEALTH AND SAFETYMANAGEMENT SYSTEM CERTIFICATE