High-Quality ASTM A500 Pre Galvanized Hollow Square Pipes

- Model

- hollow section square pipe

Item specifics

- Thickness

- 0.5- 16 mm

- OD(Outer diameter)

- 10*10-200*200mm

- Certification

- CE,LEED,BV,PHD&EPD,BC1,EN 10210,EN10219,ISO9000

- Tolerance

- as required

- Length

- 0.5-26.5M according to client requirement

- Standards

- ASTM A500

- Materials

- Gr.A, Gr.B, Gr.C

- Delivery Time

- 7-30 Days

Review

Description

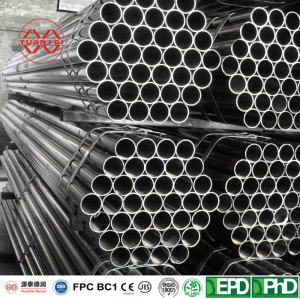

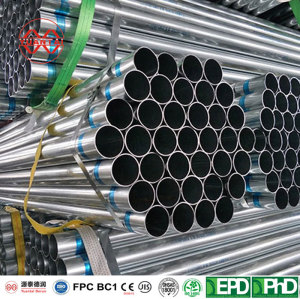

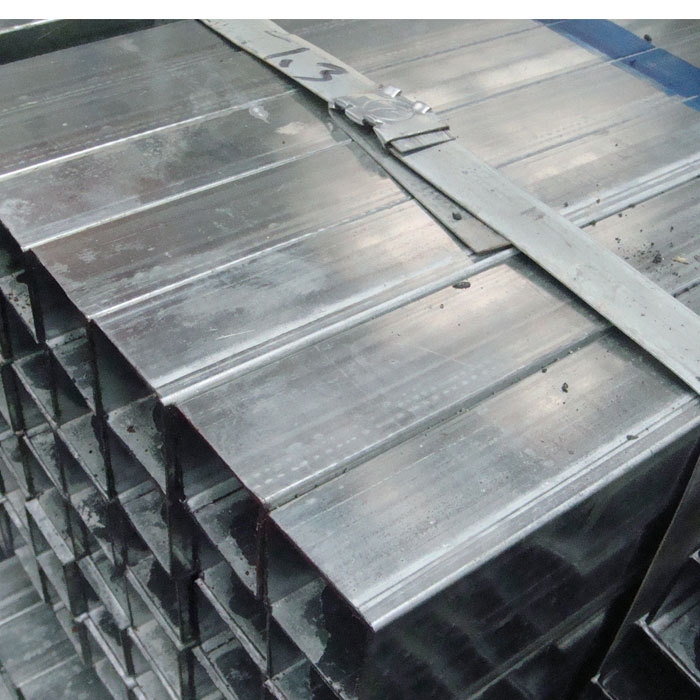

ASTM A500 Pre Galvanized Hollow Square Pipes

If you are concerned about rusting of black square tubes, ASTM A500 Pre Galvanized Hollow Square Pipes will be a good choice for you. Because ASTM A500 Pre Galvanized Hollow Square Pipes not only have the superior performance of black square tubes, but also increase better corrosion resistance and longer service life.

ASTM A500 Pre Galvanized Hollow Square Pipe is a very popular material. These pipelines are made of galvanized steel coils welded together, providing high-quality solutions for a wide range of applications. ASTM A500 Pre Galvanized Hollow Square Pipes play a crucial role in construction, engineering, and manufacturing projects.

Characteristics Of ASTM A500 Pre Galvanized Hollow Section Square Pipe:

1. Excellent strength

ASTM A500 Pre Galvanized Hollow Section Square Pipe is made from galvanized steel coils with carbon steel as the substrate, which provides excellent plasticity and support strength.

2. Better corrosion resistance

ASTM A500 Pre Galvanized Hollow Section Square Pipe is suitable for outdoor use due to its surface being protected by a zinc layer, which makes the pipe more resistant to acid and alkali corrosion and rust.

3. Easy to process

ASTM A500 Pre Galvanized Hollow Section Square Pipe has good plasticity and welding performance, making it more flexible to process.

Sizes Of Gi Galvanized Steel Hollow Square Pipe Tube

|

Type

|

Outer Diameter(mm)

|

Wall Thickness(mm)

|

Length(M)

|

|

ASTM A500 Pre Galvanized Tube

|

10*10-200*200

|

0.5-16

|

0.5-24

|

|

ASTM A500 Hot Dipped Galvanized Tube

|

10*10-1200*1200

|

0.5-60

|

0.5-24

|

Flexible Customization Options

1. Size customization

You can flexibly customize the diameter, wall thickness, and length of your pre galvanized hollow square pipe at Yuantai Derun.

2. Customization of additional processing services

You can flexibly choose some additional processing services at Yuantai Derun, such as punching, bending, cutting, welding and other processing services.

MS Pre Galvanized Hollow Square Pipe Weight Chart

|

Size(mm)

|

Pieces/Bundle

|

Weight/Bundle(Tons)

|

|

20*20*1.2

|

180

|

0.69

|

|

20*20*1.3

|

180

|

0.75

|

20*20*1.5 | 180 | 0.87 |

20*20*1.8 | 180 | 1.04 |

20*20*2.0 | 180 | 1.15 |

25*25*1.0 | 144 | 0.58 |

25*25*1.1 | 144 | 0.64 |

25*25*1.2 | 144 | 0.70 |

25*25*1.3 | 144 | 0.76 |

25*25*1.4 | 144 | 0.82 |

25*25*1.5 | 144 | 0.88 |

25*25*1.7 | 144 | 1.00 |

25*25*1.8 | 144 | 1.06 |

25*25*1.9 | 120 | 0.93 |

30*30*1.1 | 120 | 0.65 |

30*30*1.3 | 120 | 0.77 |

30*30*1.4 | 120 | 0.83 |

30*30*1.5 | 120 | 0.89 |

40*40*1.1 | 100 | 0.73 |

40*40*1.2 | 100 | 0.80 |

40*40*1.3 | 100 | 0.87 |

40*40*1.4 | 100 | 0.93 |

40*40*1.5 | 100 | 1.00 |

40*40*1.6 | 100 | 1.07 |

Free Pre Galvanized Square Hollow Section Pipe Samples For You

Yuantai Derun can supplied Free Pre Galvanized Square Hollow Section Pipe Samples For You,The sample length should be within 20 CM, and you only need to pay one shipping fee. Get Free Samples Now!

Pre Galvanized Hollow Section Square Pipe Manufacturing Process

Pre Galvanized Hollow Section Square Pipe Manufacturing Process Has those main steps:

1. Uncoiling galvanized coil 2. Edge trimming and welding 3. Straightening 4. Roll cold forming 5. High frequency welding 6. Removing excess welding bars 7 8. Water cooling 9. Cutting 10. Testing 11. Packaging and storage

Application

Pre Galvanized Hollow Section Square Pipe is used for those industries:

1. Engineering construction

2. Glass curtain wall

3. Door and window decoration

4. Steel structure

5. Guardrail

6. Mechanical manufacturing

7. Automobile manufacturing

8. Home appliance manufacturing

9. Shipbuilding

10. Container manufacturing

11. Manufacturing of electrical equipment

12. Agricultural housing construction

13. Greenhouse construction

14. Bicycle frame, motorcycle frame

15. Shelf

16. Fitness equipment

17. Leisure and tourism supplies

18. Steel wood furniture

FAQS

Q: how to calculate weight of hollow square pipe?

A: There are two ways to calculate the weight of a hollow square pipe: one is the calculation method, and the other is the actual weighing method.

1. The calculation method can first calculate the volume of the square tube, and then multiply it by the density. The weight of the hollow square tube calculated by this method may differ from the actual weight

2. The century weighing method is the actual weighing method, and the weight obtained in this way is generally more accurate.

Q: What is The Pre Galvanized square hollow pipe weight calculation formula?

A: The formula is: 4 x wall thickness x (edge length wall thickness) x 7.85 x 1.06=weight per meter (grams/meter)

Q: How to Choose: Pre Galvanized Square Hollow Pipe VS Hot Dipped Galvanized Square hollow Pipe?

A: The choice between pre galvanized square steel pipes or hot-dip galvanized square steel pipes mainly depends on your requirements for anti-corrosion performance, cost, and structural application.

The galvanized layer of pre galvanized square steel pipes is relatively thin (usually between 5-15 μ m), compared to the galvanized layer of hot-dip galvanizing (between 45-120 μ m), so its corrosion resistance is relatively weak. Suitable for general structural applications that are cost sensitive and have low requirements.

The galvanized layer of hot-dip galvanized square steel pipes is thicker and has better corrosion resistance, making it suitable for structures with higher requirements and exposed to harsh environments. In addition, hot-dip galvanized steel pipes have better toughness and plasticity, which can meet complex structural and installation requirements.

When making a choice, please consider the following factors:

Usage environment: Hot dip galvanized steel pipes should be selected in harsh environments.

Cost considerations: Pre galvanizing has lower costs and stronger economic viability.

Structural design: Select the appropriate galvanizing method according to the requirements of structural design.