4 inch square tubing galvanized pipe welding square metal tube stock

- Model

- 4 inch square metal tubing

Item specifics

- Thickness

- 0.5- 60 mm

- OD(Outer diameter)

- 4 inch

- Certification

- CE,LEED,BV,PHD&EPD,BC1,EN 10210,EN10219,ISO9000

- Tolerance

- as required

- Length

- 0.5-26.5M according to client requirement

- Standards

- ASTM A500/A501,EN10219,EN10210

- Materials

- Gr.A,Gr.B,Gr.C,S235,S275,S355,S420,S460,A36,

- Delivery Time

- 7-30 Days

Review

Description

4 Inch Square Tubing

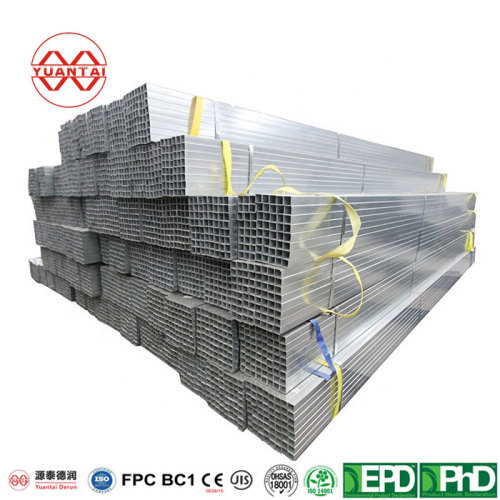

In Yuantai Derun, buyers very like 4 inch square tubing. Making pre galvanized 4 inch square tubing by directly rolling galvanized coils into shape. The surface of pre galvanized 4 inch square tubing is smoother and more attractive. Due to galvanizing, it also greatly increases the lifespan of steel pipes. so the pre galvanized 4 inch square tubing is used for many industries.

4 Inch Square Steel Tubing Characteristic

|

Coating

|

Outer Diameter(inch)

|

W.T.(mm)

|

Length(M)

|

Zinc Layer | Standard | Grade |

|

bare

|

4"×4"

|

0.5-16

|

0.5-26.5

|

No zinc coating | ASTM A500/A501,EN10219/10210,JIS G3466,GB/T6728/3094 AS1163, CSA G40.20/G40.21 | Gr.A/B/C,S235/275/355/420/460,A36,SS400,Q195/235/355,STKR400/490,300W/350W |

|

galvanized square tubing

|

4"×4"

|

1-16

|

0.5-26.5

|

Ordinary galvanizing: usually between 45-500 micrometers (μ m). | ASTM A500/A501,EN10219/10210,JIS G3466,GB/T6728/3094 AS1163, CSA G40.20/G40.21 | Gr.A/B/C,S235/275/355/420/460,A36,SS400,Q195/235/355,STKR400/490,300W/350W |

Coating

Ordinary galvanizing: usually between 45-100 micrometers (μ m).

Hot dip galvanizing: The thickness is generally between 50-500 micrometers (μ m), which may vary depending on specific requirements and applications.

Electroplated zinc: The thickness is usually between 5-30 micrometers (μ m), suitable for light load environments. Sent Your Coating Inquiry Now!

Advantages

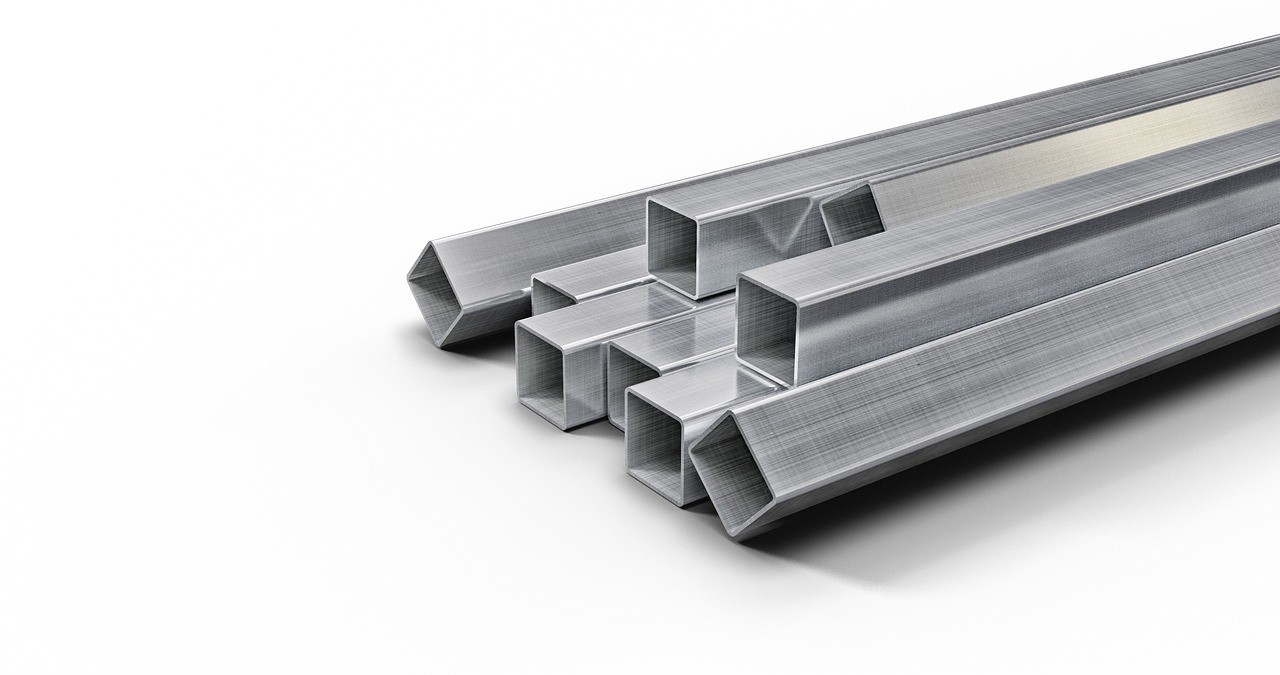

There are several advantages to using 4 inch by 4 inch square tubing.

Firstly, 4 inch square steel tubing has excellent structural properties, providing high strength and load-bearing capacity. This makes it suitable for applications that require sturdy and reliable components.

Additionally, 4 inch galvanized square tubings are versatile and easy to work with. They can be cut, welded, and shaped to meet specific design requirements, allowing for flexibility in project execution.

Lastly, 4 inch steel square tubings are cost-effective compared to other materials, making them a preferred choice for budget-conscious projects.

4 Inch Galvanized Square Tubing Free Samples For You

In order to ensure that more buyers can place orders with confidence, we have launched a free sample policy. Yuantai Derun factory can produce a sample with a length of less than 20 centimeters according to your requirements. Get free samples immediately.

Uses

4 inch square tubing have a wide range of applications and uses in various industries and sectors. Their unique structural properties make them suitable for diverse projects that require strength, durability, and versatility. Some common applications of 4 inch square tubing include:

1. Construction: 4 inch galvanized square tubings are extensively used in construction for structural support, framing, and building infrastructure. They provide stability and load-bearing capacity, making them ideal for applications such as columns, beams, and trusses.

2. Industrial Manufacturing: 4 inch galvanized square tubings are used in various manufacturing processes, including various mechanical structures, etc

FAQ

how much does 4 inch square tubing cost?

The cost of 4 inch square tubing largely depends on the price of raw materials. Considering the current fluctuation of steel prices, please consult the customer manager for specific prices.

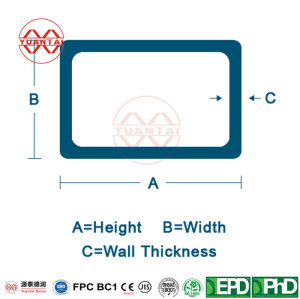

how much does 4 inch square tubing weight?

The weight of a 4-inch square tube is generally obtained by weighing, and the theoretical weight can refer to the formula for calculating the weight of the square tube:Calculation formula for rectangular tube weight: 2 x (side length 1+side length 2- wall thickness) x wall thickness x length x density kg/m Square tube weight calculation company: 4 x wall thickness x (side length wall thickness) x 7.85 kg/m