Telescoping Square Steel Tubing

- Model

- telescopic square tube

Item specifics

- Thickness

- 0.5- 60 mm

- OD(Outer diameter)

- 10*10-1200*1200mm

- Certification

- CE,LEED,BV,PHD&EPD,BC1,EN10210/10219,ISO9000

- Tolerance

- as required

- Length

- 0.5-26.5M according to client requirement

- Standards

- ASTM A500/A501/A572/A53/A106,EN10219/10210,

- Materials

- Gr.A/B/C,S235/275/355/420/460,A36/53/106/572 Gr50

- Delivery Time

- 7-30 Days

Review

Description

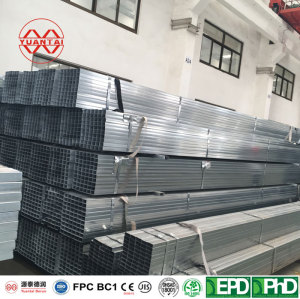

Telescoping Square Steel Tubing

As an important building material, telescoping square steel tubing has a wide range of applications. The main applications of telescoping square steel tubing include construction, machinery manufacturing, steel construction projects, shipbuilding, solar power brackets, steel structure engineering, power engineering, power plants, agricultural and chemical machinery, glass curtain walls, automotive chassis, airports, and other fields.

Customized Your Telescoping Square Tube

At Yuantai Derun, we can produce and customize two types of telescoping square tubes, namely perforated telescoping square tubes and ordinary telescoping square tubes. We mainly use ERW, LSAW, and SSAW welding processes in the manufacturing process to ensure tight welds and stable performance. In terms of raw materials, we mainly use raw materials from well-known domestic steel coil factories to provide users with greater security. The coatings for telescopic square tubes mainly include oil coating, spray painting, hot-dip galvanizing, galvanized aluminum magnesium coating, etc. Send Your Inquiry Now!

Customized options

Size: 10 * 10-1200 * 1200mm

Wall thickness: 0.5-60mm

Length: 0.5-24M

Perforation position and shape size

Telescopic Square Tubing Coating: oil coating, spray painting, galvanizing, galvanizing aluminum magnesium, etc

Manufacturing process: ERW, LSAW,SSAW,Seamless

Application Of Telescoping Steel Square Tubing

Telescoping steel square tubing is used for many industries. Such as :

In the field of architecture, telescoping steel square tubings are used to construct frame structures, support the weight of buildings, and maintain structural stability.

Mechanical manufacturing: In the mechanical manufacturing industry, telescoping steel square tubings are used to manufacture various mechanical equipment, such as machine tools, conveying equipment, etc., providing necessary structure and support.

Airport construction: In airport construction, telescoping steel square tubings are used for structural support of facilities such as runways and aprons.

Shipbuilding industry: In the shipbuilding industry, telescoping steel square tubings are used to construct ship structures, providing necessary strength and stability.

Solar power generation bracket: The telescoping steel square tubing is used in the production of solar power generation brackets to support solar panels and ensure that they can effectively capture solar energy.

Steel structure engineering: In steel structure engineering, telescoping steel square tubings are used to construct various steel structure buildings, such as sports venues, exhibition centers, etc.

Electric power engineering and power plants: In the construction of electric power engineering and power plants, telescoping steel square tubings are used as brackets for transmission lines and structural supports for power plants.

Agricultural and chemical machinery: In the field of agricultural and chemical machinery, telescoping steel square tubings are used to manufacture various equipment frames, such as irrigation systems, chemical treatment equipment, etc.

Glass curtain walls and automotive chassis: In the production of building glass curtain walls and automotive chassis, telescoping steel square tubings provide necessary structure and support.

Why choose Yuantai Derun?

- 1. 100% after-sales quality and quantity assurance.

- 2. Professional sales manager quickly reply within 24 hours.

- 3. Large Stock for regular sizes.

- 4. Free square telescoping tubing sample 20cm high quality.

- 5. Strong produce capability and capital flow.

- 6. Small order and trial order accepted.

- 7. Brand name raw material

- 8. Support OEM or ODM

- 9. 22 years Manufacturing experience

- 10. It can manufacture telescoping square steel tubings of different projects and standards in the world

FAQ

how to build telescoping square steel tubing?

The manufacturing of telescopic square steel tubings usually involves the following steps:

Material selection: Firstly, choose the appropriate steel. Expansion square tubes are generally made of carbon structural steel or low-alloy structural steel.

Cutting: Cut the raw material steel according to the design requirements to form square tube blanks.

Forming: The billet is formed into square tubes through pressure processing or heat treatment (such as cold drawing, hot drawing).

Heat treatment: Heat treat the formed square tube to improve its mechanical properties and corrosion resistance.

Surface treatment: Galvanize, spray paint and other surface treatments may be applied to the pipes as needed.

Processing correction: Cutting, chamfering, and other processing corrections are made to the pipes to meet the size and shape requirements.

Testing: Conduct strict testing on finished products, including dimensions, surface quality, mechanical properties, etc.