galvanized steel perforated square tube

- Model

- zinc-plated steel perforated square tube

Review

Description

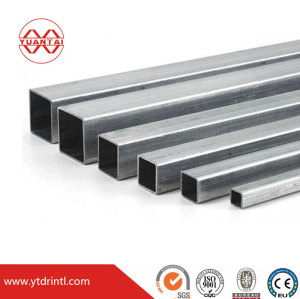

Galvanized Steel Perforated Square Tube

Galvanized steel perforated square tubes are a popular choice in various industries due to their versatility, durability, and aesthetic appeal. With their unique hole patterns, these tubes provide enhanced airflow, drainage, and structural benefits.

Making Process

At Yuantai Derun, the manufacturing of galvanized perforated square tubes is divided into the following steps.

The first step is to unwind the carbon steel coil, roll it into shape, and perform high-frequency welding to produce carbon steel square tubes.

The second step is to laser punch the finished carbon steel square tube and make it into a punched square tube.

The third step is to perform acid washing, hot-dip galvanizing, passivation and other steps on the punched square tube to form hot-dip galvanized(HDG) perforated square tube.

Characteristic

Galvanized steel perforated square tubes Having many advantages.

1.Corrosion Preventive

Galvanized steel perforated square tubes have improved oxidation resistance due to a layer of zinc coating on the surface. Compared to ordinary carbon steel perforated square tubes, hot-dip galvanized perforated square tubes are more corrosion-resistant and have an extended service life.

2.Wear Resistant

Galvanized steel perforated square tube is more wear-resistant than ordinary perforated steel square tube due to the addition of a thick zinc layer.

3.Versatility and Flexibility

With a wide range of hole sizes, shapes, and patterns available, perforated square tubes offer versatility in design. They can be customized to meet specific requirements, allowing for flexibility in various applications.

4.Enhanced Air and Water Flow

The perforations in these tubes promote better airflow and water drainage, making them ideal for ventilation systems, filters, and drainage pipes. This feature is especially useful in industrial and automotive applications.

Size Of Galvanized Punched Square Tube

The size of galvanized perforated square tube is very complete, ranging from 10 * 10mm to 1200 * 1200mm, with wall thickness from 0.5-60mm, and the length can be cut according to your needs.

|

Name

|

Outer Diameter(mm)

|

Wall Thickness(mm)

|

Length(M)

|

|

Punched Square Tube

|

10*10~1200*1200

|

0.5-60

|

0.5-26.5

|

Zinc Coating Layer Thickness

The weight range of the zinc coating on galvanized punched square tubes is between 180 grams per square meter and 270 grams per square meter. This standard usually applies to the process of hot-dip galvanizing (HSP). You can also inform us of the requirements for zinc coating, and we can produce according to your requirements.

Grade Of Plated Steel Perforated Square Tube

At Yuantai Derun, there are many steel grades available for plated steel perforated square tube, such as Gr. A/B/C, S235/275/355/420/460, A36, SS400, Q195/235/355, STKR400/490300W/350W, etc. You can also directly send your steel grade requirements to our customer manager.

Customized Options

At Yuantai Derun, you can also customize the punching shape, size, spacing distance, and more of square steel pipes. Send your request immediately.

Common Applications

Galvanized Perforated square tubes find applications in a wide range of industries and sectors. Some common examples include:

1.Construction and Architecture: Perforated metal tube squares are used in building structures, gates, fences, and railing systems, providing both functional and decorative elements.

2.Industrial and Manufacturing: Galvanized Perforated square tubes are widely used in machinery, equipment, and storage systems due to their strength, ventilation capabilities, and ease of fabrication.

3.Automotive and Transportation: Perforated steel square tube can be found in exhaust systems, air filters, and other parts where airflow and durability are critical.

4.Outdoor and Landscape Design: Perforated square tubes are used in outdoor furniture, sculptures, and decorative panels to create unique designs while allowing for better ventilation and drainage.

Reliable China Perforated Rectangular Steel Tubes Manufacturer-Yuantai Derun

In China, Yuantai Derun is known for manufacturing high-quality perforated rectangular steel tubes. These tubes offer similar benefits and applications but with a different shape. The rectangular shape allows for more flexibility in design and installation, making them suitable for a variety of construction and manufacturing projects.

FAQs

Q1. Are china perforated square tube only available in steel material?

A1. No, perforated square tubes can also be made from other materials like aluminum and stainless steel, depending on the specific requirements of the application.

Q2. Can perforated square tubes be custom-made?

A2. Yes, perforated square tubes can be customized in terms of hole patterns, sizes, and materials to meet specific project needs.

Q3. Are perforated square tubes suitable for outdoor applications?

A3. Yes, perforated square tubes, especially those made from galvanized or zinc-plated steel, are ideal for outdoor applications as they offer excellent corrosion resistance.

Q4. Can perforated square tubes be used for decorative purposes?

A4. Absolutely! Perforated square tubes are often chosen for their aesthetic appeal and can be used to create unique and visually appealing designs in architecture and interior design projects.

Q5. How do I clean perforated square tubes?

A5. Cleaning perforated square tubes is simple. Use a mild detergent and water to remove dust and dirt from the surface. For stubborn stains, a non-abrasive cleaner can be used.

Q6. china galvanized perforated square tube size

A6. Commonly used sizes include 20 * 20mm, 25 * 25mm, 30 * 30mm, etc. Among them, 20 * 20mm pipes are the narrowest and thinner, making them suitable for lightweight structures.

Q7.How to maintain Perforated Square Tubes?

To ensure the longevity of perforated square tubes, proper maintenance is essential. Some tips for maintenance include:

1.Cleaning and Rust Prevention: Regularly clean the tubes using mild detergent and water. Inspect for any signs of rust and apply appropriate rust prevention techniques, such as coatings or paints.

2.Protective Coatings and Paints: Apply protective coatings such as zinc or epoxy to prevent corrosion and enhance durability, especially in outdoor or corrosive environments.