Rectangular tube for shipbuilding China(OEM OBM ODM)

- Model

- Rectangular tube for shipbuilding

Item specifics

- Thickness

- 0.5-60mm

- OD(outer diameter)

- 10*10mm-1000*1000mm

- Grade

- Gr.A,Gr.B,Gr.C,S235,S275,S355,S420,S460,A36,

- Surface

- Customers't Requirement

- Delivery Time

- 7-30 Days

- Standards

- Hollow section: ASTM A500/A501,EN10219, EN10210etc

- Length

- 3-12M according to client requirement

- Tolerance

- standard or as required

- Certification

- CE,LEED,BV,PHD&EPD,BC1,EN10210,EN10219,ISO9000,etc

- Supply capacity

- Annual output of 5 million tons

Review

Description

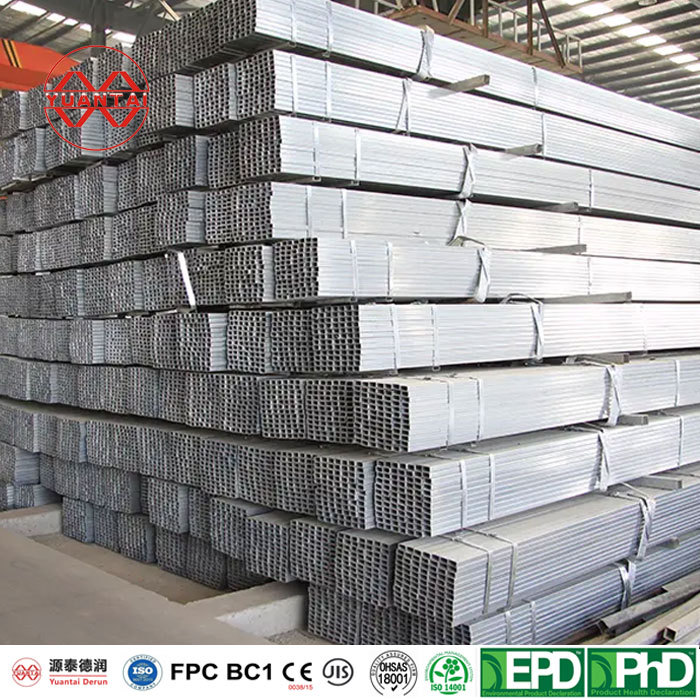

Rectangular tube for shipbuilding China(OEM OBM ODM)

Introduction:

1.Importance of rectangular tubes in shipbuilding

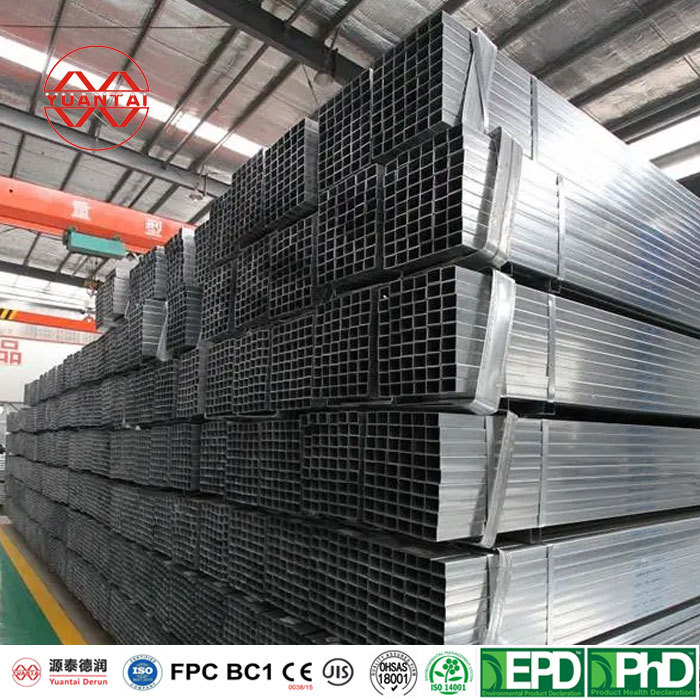

In the shipbuilding industry, the choice of materials plays a crucial role in ensuring the durability and safety of vessels. One significant component used in ship construction is rectangular tubes.

2.The role of rectangular steel pipes in the industry

These tubes offer numerous advantages, ranging from their strength and durability to their space efficiency and versatility in design. Additionally, the availability of rectangular steel pipes, manufactured by reliable exporters and carbon steel pipe manufacturers, further contributes to the growth of the shipbuilding industry. In this article, we will explore the importance of rectangular tubes in shipbuilding, the role of exporters and manufacturers, and the significance of hot dip galvanized steel pipe suppliers.

Rectangular Tube for Shipbuilding

1.Advantages of using rectangular tubes for ship construction

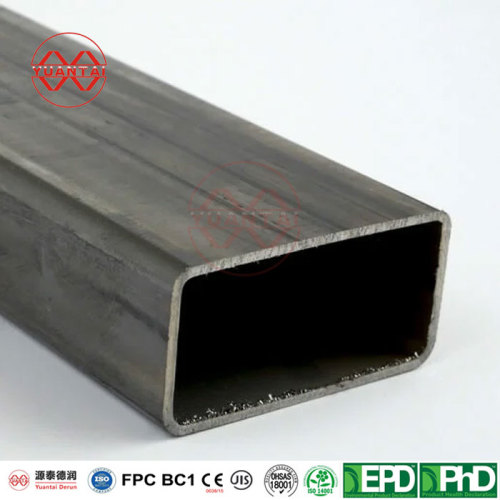

Strength and Durability

Rectangular tubes provide exceptional strength and durability, making them ideal for ship construction. These tubes can withstand harsh environmental conditions, ensuring the longevity and safety of the vessels. The rectangular shape offers enhanced load-bearing capabilities compared to other tube shapes, making it an efficient choice for ship design.

Space Efficiency

Shipbuilding requires careful consideration of space utilization. Rectangular tubes, with their flat sides, allow for efficient space management in vessel construction. This enables shipbuilders to maximize the available space, resulting in better utilization and increased efficiency onboard.

Versatility in Design

Rectangular tubes offer versatility in ship design. The shape allows for easy fitting and integration into various structural components of the vessel. Shipbuilders can utilize rectangular tubes for framework, bulkheads, pipelines, and other essential applications, facilitating the construction process and ensuring a well-designed and functional vessel.

Rectangular Steel Pipe Exporter of Yuantai Derun steel pipe group

Finding a reliable rectangular steel pipe exporter is essential for shipbuilding projects. An exporter acts as a crucial link between manufacturers and buyers, ensuring the seamless flow of quality products. When choosing an exporter, it is important to consider their experience, reputation, and customer reviews. A reputable exporter will prioritize quality assurance, timely delivery, and customer satisfaction. Collaborating with a reliable exporter offers numerous benefits, including access to a wide range of products, competitive pricing, and expert guidance throughout the procurement process.

Universal structural Carbon Steel Pipe Manufacturer

12 factories, 72 production lines, 63 patented technologies, China's top 500 private enterprises and China's top 500 manufacturing industries, with an annual output of 5 million tons and a perennial spot supply of 200000 tons. China's largest square tube manufacturer.

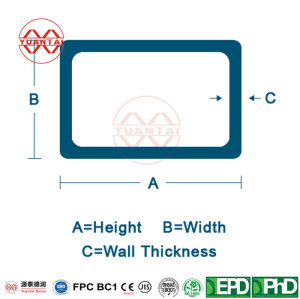

Rectangular steel tubing sizes and properties

Carbon steel pipes play a vital role in various industries, including shipbuilding. As a versatile and durable material, carbon steel is widely used in pipe manufacturing. A reliable carbon steel pipe manufacturer ensures the production of high-quality pipes that meet industry standards. When choosing a manufacturer, it is important to consider their expertise, adherence to quality standards, and certifications. Collaborating with a reputable manufacturer guarantees the sourcing of reliable and durable carbon steel pipes for shipbuilding projects.

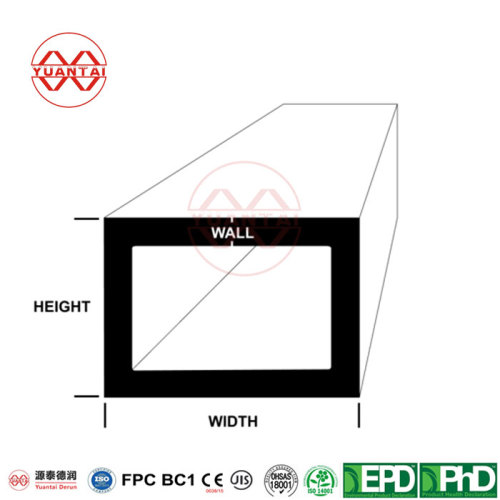

Exploring the characteristics and features of rectangular tubes

Rectangular tubes, available in various dimensions and materials, offer unique characteristics that make them suitable for several applications. Shipbuilding is one of the industries that significantly benefit from the use of rectangular tubes.

Pipe orifice leveling

Widely used

Uniform thickness

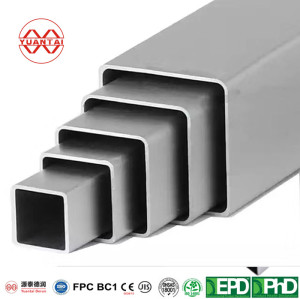

Different types of rectangular tubes available in the market

These tubes provide excellent strength and structural support while allowing shipbuilders to optimize space utilization. Within the shipbuilding industry, rectangular tubes find applications in the construction of hulls, bulkheads, cabins, handrails, and engine components. The availability of different types of rectangular tubes allows for customization and flexibility in ship design.

excellent strength and structural support

Support customization of marine rectangular tubes of different specifications and types

Complete specifications and sufficient inventory

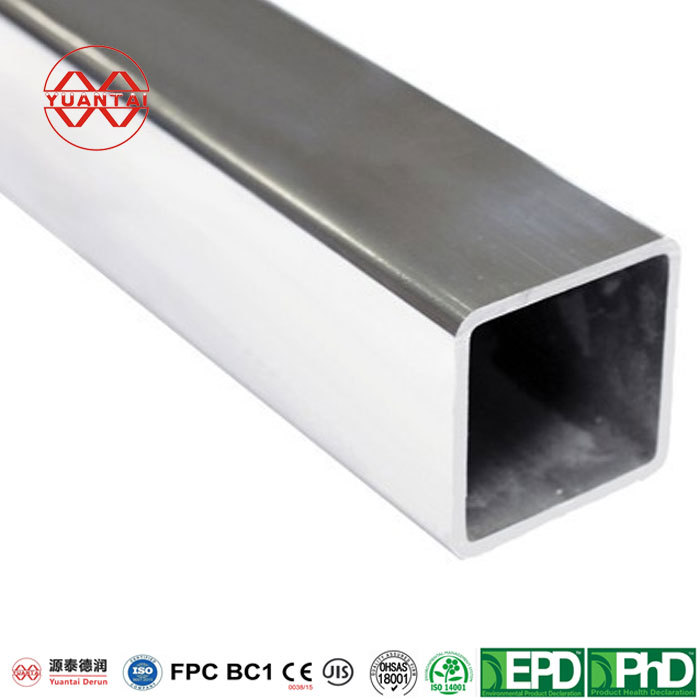

Understanding the properties and benefits of rectangular steel tubes

Rectangular steel tubes boast exceptional properties that make them valuable in multiple sectors, including shipbuilding.

Applications of rectangular steel tubes in different sectors

These tubes possess high tensile strength, excellent resistance to corrosion, and a high load-bearing capacity. In ship construction, rectangular steel tubes find applications in structural support, framework, ventilation systems, and piping networks, among others. The ability of these tubes to withstand extreme environmental conditions and provide structural integrity make them a preferred choice in shipbuilding projects.

Rectangular Steel Tube Factory CERTIFICATE

Choosing a reliable rectangular steel tube factory is crucial for ensuring the quality and timely supply of products. A reputable factory emphasizes the use of high-quality materials, adherence to industry standards, and efficient production processes. When selecting a factory, factors such as experience, reputation, certifications, and customer reviews should be taken into consideration. Collaborating with a reliable factory ensures the procurement of superior rectangular steel tubes, meeting the specific requirements of shipbuilding projects.

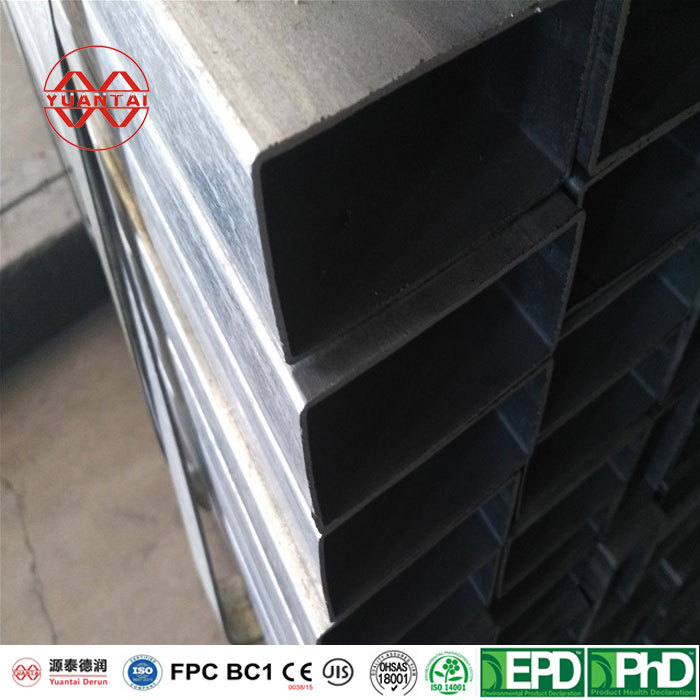

Rectangular steel tubing

Rectangular tube is a light-weight thin-walled steel tube with rectangular section, also known as steel cold-formed profile. It is a section steel with square section shape and size made of Q235 hot-rolled or cold-rolled strip or coil as the base material, cold bending and high-frequency welding. When the bending and torsional strength are the same, the weight is light, so it is widely used to manufacture mechanical parts and engineering structures.

| square and rectangular hollow section Unit: mm | |||||

| Non-standard size | standard size | thickness | non-standard size | standard size | thickness |

| 1.0 | 1.5 | ||||

| 1.2 | 1.7 | ||||

| 1.3 | 40*135 | 50*150 | 2.0 | ||

| 19*19 | 20*20 | 1.4 | 50*140 | 60*140 | 2.2 |

| 1.5 | 60*130 | 80*120 | 2.5~5.0 | ||

| 153 | 1.7 | 75*125 | 100*100 | 5.25~6.0 | |

| 2.0 | 6.5~9.75 | ||||

| 1.0 | 395 | 11.5~16 | |||

| 1.2 | 50*160 | 2.5 | |||

| 1.3 | 60*150 | 60*160 | 2.75 | ||

| 25*25 | 1.4 | 60*180 | 80*140 | 3.0~4.0 | |

| 1.5 | 65*180 | 80*160 | 4.25~4.75 | ||

| 153 | 20*30 | 1.7 | 70*150 | 100*150 | 5.25~6.0 |

| 1.8 | 90*150 | 120*120 | 6.5~7.75 | ||

| 2.0 | 90*160 | 110*110 | 9.5~9.75 | ||

| 2.2 | 100*120 | 120*180 | 10.5~11.75 | ||

| 2.5~3.0 | 100*125 | 125*125 | 12.5~15.75 | ||

| 1.0 | 100*140 | 470 | 16~~30 | ||

| 20*40 | 1.2 | 60*170 | 75*150 | 2.5 | |

| 20*50 | 1.3 | 70*16070*200 | 100*200 | 2.75 | |

| 25*40 | 1.4 | 80*150 | 140*140 | 3.0~5.75 | |

| 32*32 | 1.5 | 80*180 | 150*150 | 7.5~9.75 | |

| 30*30 | 1.7 | 127*127 | 130*130 | 10.5~11.75 | |

| 35*35 | 1.8 | 570 | 12.5~15 | ||

| 30*40 | 2.0 | 60*200 | 100*250 | 2.5 | |

| 2.2 | 60*220 | 160*160 | 2.75~3.25 | ||

| 2.5~3.0 | 80*200 | 180*180 | 3.5~5.0 | ||

| 232 | 3.5~3.75 | 80*220 | 140*180 | 5.25~7.75 | |

| 1.2 | 100*180 | 150*170 | 9.5~11.75 | ||

| 1.3 | 120*160 | 150*180 | 12.5~15.75 | ||

| 1.4 | 120*200 | 150*200 | 16~~30 | ||

| 20*60 | 25*50 | 1.5 | 100*350 | 2.75 | |

| 20*80 | 30*50 | 1.7 | 125*250 | 3.0~3.25 | |

| 25*65 | 30*60 | 1.8 | 130*250 | 100*300 | 3.5~9.75 |

| 30*70 | 40*40 | 2.0 | 135*135 | 150*250 | 11.5~11.75 |

| 35*60 | 40*50 | 2.2 | 140*240 | 200*200 | 12.5~14.75 |

| 38*38 | 40*60 | 2.5~4.0 | 150*220 | 200*250 | 15.5~15.75 |

| 45*45 | 50*50 | 4.25~5.0 | 225*225 | 770 | 16~~30 |

| 5.25~5.75 | 100*400 | 150*300 | 3.5~4.0 | ||

| 153 | 5.75~6.0 | 130*300 | 200*300 | 4.5~7.75 | |

| 1.3 | 150*350 | 250*250 | 9.5~11.75 | ||

| 1.4 | 200*280 | 180*300 | 12.5~14.75 | ||

| 30*100 | 40*80 | 1.5 | 220*220 | 1010 | 15.5~17.75 |

| 40*70 | 40*100 | 1.7 | 200*350 | 200*400 | 4.75~11.75 |

| 40*90 | 50*70 | 1.8 | 250*350 | 250*300 | 12.5~14.75 |

| 50*60 | 50*80 | 2.0 | 300*300 | 15.5~17.75 | |

| 50*75 | 60*60 | 2.2 | 200*500 | 4.75~11.75 | |

| 50*90 | 60*80 | 2.5~4.0 | 300*320 | 250*450 | 12.5~14.75 |

| 55*55 | 70*70 | 4.25~5.0 | 300*350 | 300*400 | 15.5~17.75 |

| 65*65 | 5.25~5.75 | 350*350 | 18~~30 | ||

| 232 | 5.75~6.0 | 200*450 | 200*600 | 4.5~5.75 | |

| 1.3 | 250*400 | 280*280 | 6.5~11.75 | ||

| 40*120 | 50*100 | 1.5 | 250*500 | 300*500 | 12.5~14.75 |

| 40*140 | 60*90 | 1.7 | 300*450 | 350*400 | 15.5~17.75 |

| 50*110 | 60*100 | 1.8 | 400*400 | 18~~30 | |

| 50*120 | 60*120 | 2.0 | 300*650 | 300*600 | 4.5~7.75 |

| 50*125 | 75*75 | 2.2 | 400*500 | 9.5~9.75 | |

| 70*100 | 80*80 | 2.5~4.0 | 300*700 | 400*600 | 11.5~13.75 |

| 85*85 | 80*100 | 4.25~5.0 | 450*450 | 14.5~15.75 | |

| 90*90 | 5.25~5.75 | 320*320 | 500*500 | 16.5~17.75 | |

| 312 | 7.5~9.75 | 18~~30 | |||

| 1300*1300 | 70~80 | ||||

| The length, width and thickness of other specifications can be customized | |||||

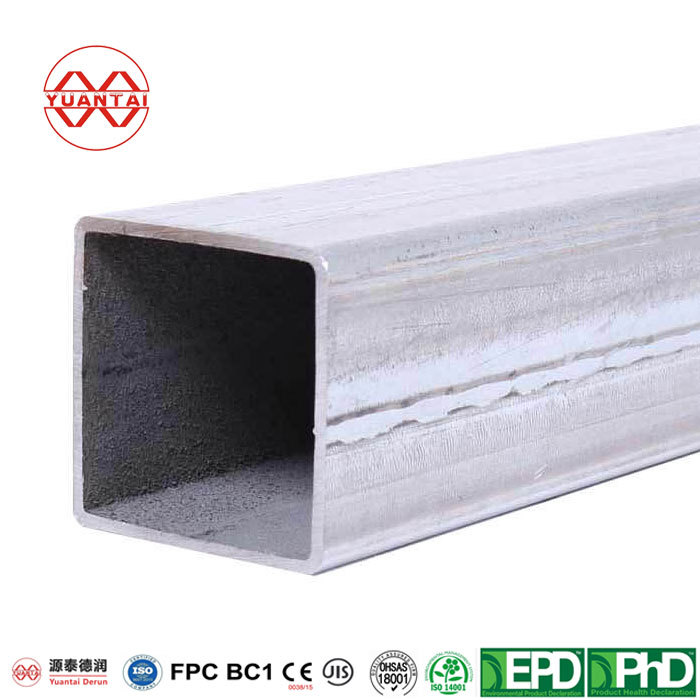

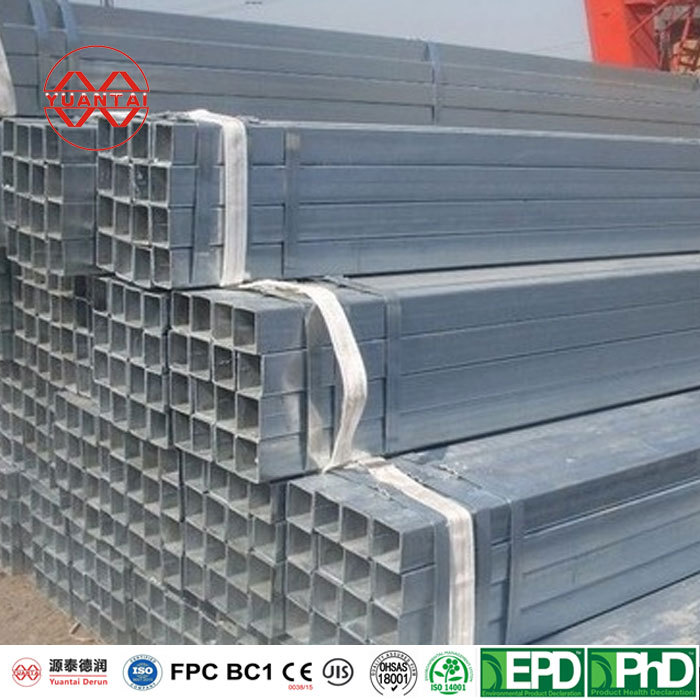

VIDEO OF Hot Dip Galvanized Steel Pipe Supplier

In various industries, including shipbuilding, the use of hot dip galvanized steel pipes is prevalent. These pipes undergo a process of coating with a protective zinc layer, enhancing their resistance to corrosion and extending their lifespan. Finding a reliable hot dip galvanized steel pipe supplier is essential for sourcing high-quality pipes. A reputable supplier will ensure the strict adherence to industry standards, provide timely delivery, and offer expert advice on choosing the right pipes for shipbuilding projects. The utilization of hot dip galvanized steel pipes in ship construction enhances the durability and longevity of the vessels, thereby ensuring their safety and reliability.

PROJECT

AIRPORT VENUES

Black high-frequency welded pipes are indispensable in airport venue buildings,Black high-frequency welded pipes are indispensable in the airport venue buildings. This is our cooperation project Beijing Daxing International Airport

EXPO VENUES

2020 Dubai World Expo venue,The 2020 Dubai World Expo venue is one of the projects we participate in

Conclusion

In the shipbuilding industry, the use of rectangular tubes, manufactured by reliable exporters and carbon steel pipe manufacturers, is essential for constructing strong and efficient vessels. Rectangular tubes offer superior strength, space efficiency, and versatility in design, making them an ideal choice for various shipbuilding applications. Choosing a trustworthy rectangular steel tube factory and a reliable hot dip galvanized steel pipe supplier ensures the procurement of high-quality products that meet industry standards. By giving careful attention to the selection of materials and suppliers, shipbuilders can ensure the durability, safety, and longevity of the vessels they construct.

Why choose YuantaiDerun?

- 1. 100% after-sales quality and quantity assurance.

- 2. Professional sales manager quickly reply within 24 hours.

- 3. Large Stock for regular sizes.

- 4. Free sample 20cm high quality.

- 5. Strong produce capability and capital flow.

- 6.small order accepted.

- 7.Brand name raw material

- 8.support OEM or ODM

- 9.20 years Manufacturing experience

- 10. It can manufacture steel pipes of different projects and standards in the world

- 11.Yuantai has a standing stock of more than 200000 tons, and the annual shipment specification is: 20*20*1.0—1000*1000*50mm,20*30*1.0—800*1200*50mm,Φ 219— Φ 1420mm,The black, hot-dip galvanized rectangular pipe and spiral welded pipe made of q195-q460 have an existing capacity of nearly 5 million tons,

- 12.After the completion of the new base in Tangshan, the total production capacity will reach 10 million tons.

FAQs

Q: Are rectangular tubes common in shipbuilding?

A: Yes, rectangular tubes are widely used in ship construction due to their superior strength and space efficiency.

Q: What should I look for in a reliable rectangular steel pipe exporter?

A: It is important to consider factors such as experience, reputation, quality assurance, and customer reviews when choosing an exporter.

Q: Why is carbon steel widely used in pipe manufacturing?

A: Carbon steel offers excellent durability and corrosion resistance, making it a popular choice for pipe production in various industries.

Q: What are some common applications of rectangular steel tubes?

A: Rectangular steel tubes have diverse applications, including construction, automotive, furniture, and agricultural sectors.

Q: Is hot dip galvanization necessary for steel pipes?

A: Hot dip galvanization provides added protection against corrosion, making it a valuable process for steel pipes in various industries.