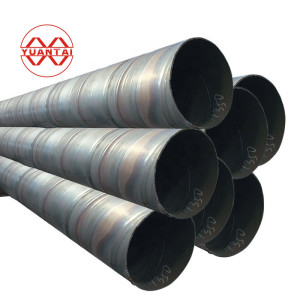

Steel sleeve lined FBE anti-corrosion insulation spiral steel pipe

- Model

- FBE spiral steel pipe

Item specifics

- Standard

- API 5L, ASTM A501/500, bs,EN10210/10219,JIS G3466

- Thickness

- 4mm to 30mm

- Outer Diameter(OD)

- 219mm to 2032mm

- Application

- Fluid transport or building structure

- Certification

- API/SGS/BV/JIS/EN/ISO/CE/BC1/GB/EPD&PHD/LEED

- Alloy Or Not

- Non-Alloy

- Length

- 3m-24meters or as client required

- Packing

- Loosed PCS/nylon rope(for the coating pipes)

- Delivery Time

- 7-30 Days

- Grade

- Gr.A,Gr.B,Gr.C,S275J0H,S355JR,S355J0H,S355J2H,Q195

Review

Description

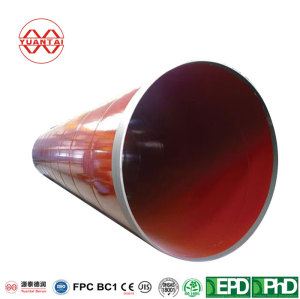

Steel Sleeve Lined FBE Anti-Corrosion Insulation Spiral Steel Pipe

Steel Sleeve Lined FBE Anti-Corrosion Insulation Spiral Steel Pipe is a new kind of insulation steel pipe.

Steel casing insulation burial technology is a waterproof, leak-proof, impermeable, pressure-resistant and fully enclosed buried new technology, is directly buried laying technology in the water table in the use of higher areas of a larger breakthrough. It is by the transmission medium of the steel pipe, anticorrosion jacket steel pipe and steel pipe and jacket steel pipe filled with ultra-fine glass wool between the combination, but also can be used graphite, calcium silica tile pipe shell and filled with polyurethane foam composite.

Standards

The Steel Sleeve Lined FBE Anti-Corrosion Insulation Spiral Steel Pipe complies with the industry standards CJ/T 114-2000 and CJ/T 115-2001 for urban construction in the People's Republic of China.

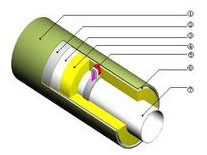

Thermal Insulation Structure

1. Anti corrosion coating: protects the outer steel pipe from corrosive substances, prolongs the service life of the steel pipe.

2. Outer protective steel pipe: protects the insulation layer from groundwater erosion, supports the working pipe and can withstand certain external loads, ensuring the normal operation of the working pipe.

3. Polyurethane foam layer: ensure the medium temperature, and ensure that the surface of the external protection pipe is kept at normal temperature.

4. Barrier and reflective layer: ensure that the organic foam material does not enter the inorganic hard high temperature resistant layer; Reflect some heat from the high-temperature resistant layer.

5. Inorganic hard thermal insulation layer: resistant to high temperature, ensuring the interface temperature between organic thermal insulation layer and foam not to be carbonized.

6. Drag reduction layer: Ensure the free movement of the working steel pipe during thermal expansion and contraction.

7. Working steel pipe: Ensure the normal flow of the conveying medium.

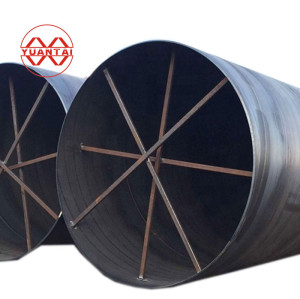

The insulation structure of steel sleeve steel insulation pipe is divided into internal sliding type and external sliding type according to different sliding modes.

1. Internal sliding type: The insulation structure consists of a working steel pipe, aluminum silicate, drag reduction layer, microporous calcium silicate, insulation layer, stainless steel fastening steel strip, aluminum foil reflective layer, polyurethane insulation layer, outer steel pipe, and external anti-corrosion layer.

2. External sliding type: The insulation structure consists of a working steel pipe, a glass wool insulation layer, an aluminum foil reflective layer, a stainless steel fastening strap, a sliding guide bracket, an air insulation layer, an external protective steel pipe, and an external anti-corrosion layer.

Structural diagram of steel sleeve steel insulation pipe: (see above figure)