ASTM A572 Grade 50 Round Seamless Carbon Steel Pipe High Strength Low Alloy (HSLA) Pipe

- Model

- astm a572 grade 50 pipe

Item specifics

- Certificate

- ISO/CE/ASTM/AS

- Delivery time

- 7-30 days

- Tolerance

- as required

- Thickness

- 2mm-50mm

- Length

- 0.5-24m or as required

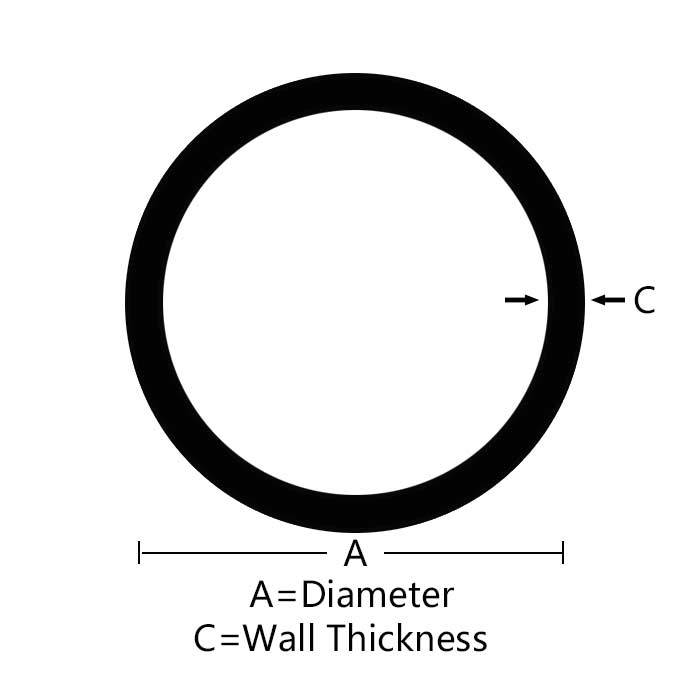

- Diameter

- round:21.3mm-820mm

- Grade

- Grade 50

- Supply capacity

- Annual output of 1 million tons

Review

Description

ASTM A572 Grade 50 Round Seamless Carbon Steel Pipe High Strength Low Alloy (HSLA) Pipe

ASTM A572 Grade 50 Carbon Steel Seamless Pipe Supplier Overview

The ASTM A572 standard refers to high-strength low alloy steel pipes (HSLA Pipes) that comply with the American standard ASTM A572. The ASTM A572 standard includes multiple HSLA grades, such as grade 42, grade 50, grade 55, grade 60, and grade 65. The grades in ASTM A572 standard are related to the strength of the steel. For example, the strength of ASTM A572 grade 50 HSLA pipes is approximately 380 Mpa.The strength of grades 42, 55, 60 & 65 in MPa is as follows: 290, 380, 415, and 450.

Yuantai Derun is a large ASTM A572 Grade 50 Carbon Steel Seamless Pipe Supplier in China.It is the largest manufacturer of structural steel pipes in China,we can produce ASTM A572 Grade 50 Carbon Steel Seamless Pipe :

Diameter:21.3-820mm

Wall Thickness:0.5-60mm

Length:0.5-24M

ASTM A572 Steel Pipe Classification

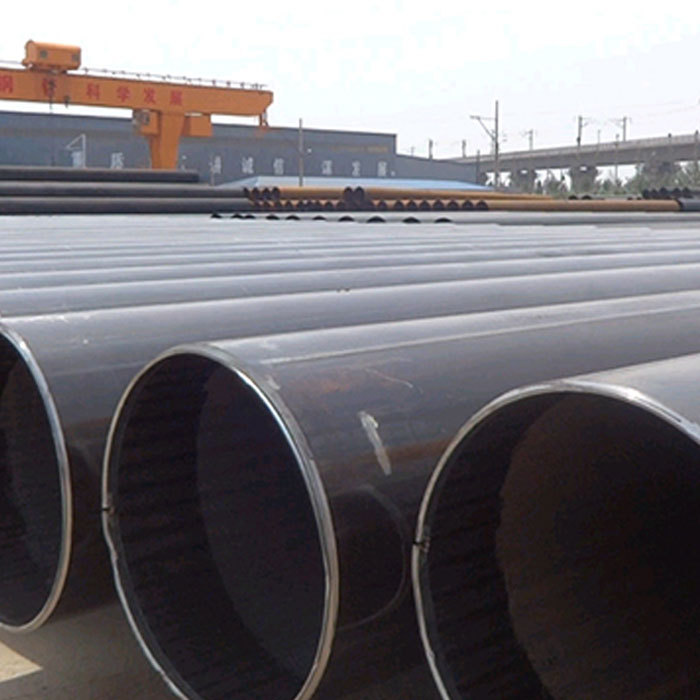

ASTM A572 steel pipe is divided into two categories, one is seamless steel pipe and the other is welded steel pipe.

ASTM A572 Grade 50 High Strength Low Alloy Pipes are divided into hot rolled seamless alloy steel tubes, cold-rolled pipes, cold-drawn pipes, extruded pipes, top pipes, etc. according to different production methods, and all have their own process regulations.ASTM A572 carbon steel welded pipe are divided into ERW steel pipe,spiral welded steel pipe,LSAW steel pipe. Contact Us Now

ASTM A572 Grade 50 Pipe Specification

Various wall thickness of ASTM A572 Gr. 42, 55, 65 Pipe Contact Us Now

|

Name |

Standards

|

O.D.

|

W.T.

|

|

ASME Sa572 Gr 50 Seamless Pipe Size

|

AISI, DIN, EN, GB, IS, JIS, ASTM, ASME Pipe

|

21.3-820mm

|

4-60mm

|

|

Steel A572 Grade 50 Welded Pipe Size

|

10.3-1620mm

|

0.5-30mm

|

|

|

Steel ASTM A572 ERW Pipe size

|

10.3-609mm

|

0.5-16mm

|

|

Carbon Steel A572 Tube Swg & Bwg | 10 Swg., 12 Swg., 14 Swg., 16 Swg., 18 Swg., 20 Swg. | ||

Steel A572-50 Pipe Schedule | SCH5, SCH10, SCH10S, SCH20, SCH30, SCH40, SCH40S, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS | ||

A572 Grade 50 Spiral Steel Tube Size | 219-3620mm | 4-30mm | |

Carbon Steel A572 LSAW Welded Tube Size | 355.6-1420mm | 4-30mm | |

ASME Sa572 Grade 50 Swg & Bwg | 10 Swg., 12 Swg., 14 Swg., 16 Swg., 18 Swg., 20 Swg. | ||

Usage

1.Pipes or structural elements for the transportation of fluids

2.High strength low alloy or HSLA ASTM A572 Grade 55 for welded, bolted or riveted structures in bridges or buildings

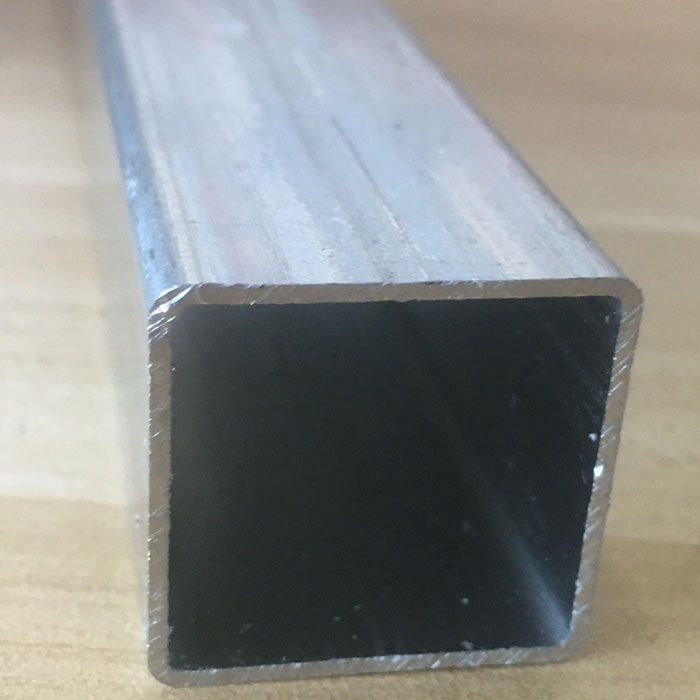

3.A572 Grade 50 carbon steel tubing is often used in round, hydraulic, “U” bend or hollow tubing, straight seam submerged arc welded tubing, boiler tubing, straight tubing, composite tubing, rectangular tubing, square tubing, and more.

4.A572 Grade 50 carbon steel tubing is often used in petroleum tubing, gas tubing, fluid tubing, boiler tubing, and heat exchanger tubing.

if you have any problem,please contact our manager

Manufacturing Process

The production process of ASTM A572 seamless alloy steel pipes is divided into the following steps:

Round bar → Heating → Piercing → Three roll oblique rolling, continuous rolling or extrusion → Tube detachment → Sizing (or reducing) → Cooling → Straightening → Hydrostatic testing (or flaw detection) → Marking → Warehousing.

Seamless steel pipes are made from steel ingots or solid billets that are perforated into tubes, and then hot-rolled, cold-rolled, or cold-drawn.

Seamless steel pipes are mainly divided into hot rolled seamless steel pipes, cold drawn seamless steel pipes, and cold rolled seamless steel pipes. This article mainly provides a detailed explanation of these three production processes.

Seamless steel pipes for general pipelines, pipeline processing flowchart: Contact Us

Chemical Composition

|

ASTM A572 GR.50 Welded ERW Carbon Steel Pipe Chemical Composition

|

||||

|

Grade

|

C

max.% |

Mn

max.% |

P

max.% |

S

max.% |

|

50(345)

|

0.23

|

1.35D |

0.04

|

0.05

|

A572 Steel Pipe Mechanical Properties Chart

|

A572 Gr 50 Material Properties

|

Yield Point, min ksi [MPa]

|

Tensile Strength, min ksi [MPa] |

Minimum Elongation, % B,C,D | |||

|

50 [345]

|

ksi

|

Mpa

|

ksi |

Mpa

|

in8in.

[200 mm] | in2in.

[50 mm] |

|

50

|

[345]

|

65 |

[450]

|

18 | 21 | |

Type

Specification Sheet Of ASTM A572 Grade 50 High Strength Low Alloy Pipe

size | size | size |

12×1.5 | 73×4-4.5-5-6-7-8-9-10-12-15 | 219×30-40 |

14×1.5-2.5-3 | 76×4-4.5-5-6-7-8-9-10-12-14 | 245×8-10-14-17-20-22 |

16×1.5-2.5-4 | 83×4.5-5-10/ 12 14 16 18 20 | 245×25-28-30-34-40 |

18×2.3-4-5 | 89×4.5-8-10/12-14 16 -18 20 | 273×7-9-12-15-18-20-25 |

20×2.5-3-5 | 95×4.5-6-8/10-12-14-16-20 | 273×30-35-38-40 |

24×2.5-3-4-5-6 | 102×4.5-5-6-7-8-10-12-14-16-20 | 299×8-12-16-20-24-28 |

25×2.5-3-4-5-6 | 108×4.5-5-6-7-8-10/12-14-18-20-22 | 299×30-32-36-38-40 |

28×3-3.5-4-5-6 | 114×4.5-5-6-7-8-10-12-14-18-20 | 325×8-12-14-18-38 |

32×3.5-4-5-6-8 | 121×4.5-5-6-7-8-10-12-14-16-20 | 325×28-32-34-38 |

34×4-5-6-8 | 127×4.5-5-6-7-8-10-12-14-16-20 | 351×10-16-20-25-40 |

36×3.5-5-6-8 | 133×4.5-6-8-12-14-16-18-20-25-30 | 355×6-18-20-25-30-40 |

38×4-5-6-7-8-9-10 | 140×5-6-7-8-9-10/12-14-16-20-22 | 377×8-12-15-20-24-28 |

39×3.5-5-8-10 | 146×4.5-6-8-12-14-16-18-20-25-30 | 377×30/37/40 |

42×3.5-4-5-6-7-8-9-10 | 152×4.5-6-8-12-14-16-18-20-25-30 | 402×10/15-20-25-30-35 |

45×3.5-4-5-6-7-8-9 | 159×4.5-6-10-12-14 | 406×10/20-25-28-35-40 |

48×3.5-4-5-6-7-8-9-10 | 159×16-18-20-22-25-30 | 426×10/12-14-16-20-25-30-35-40 |

51×3.5-4-5-6-7-8-9-10 | 168×8-10/12/14/20/25/30/35 | 450×10/12-14-16-20-25-34-40 |

56×3.5-4-5-6-7-8-9-10 | 180×8-12-16-25-30 | 480×10/ 12 14 16 18 20 25 30 40 |

57×3.5-5-6-7-8-9-10-12 | 180×32-34-38-40 | 500×10/12-14-16-20-25-34-40 |

60×3.5-4.5-5-6-7-8-9-12-14 | 194×6-8-12-16-20-25-30-40 | 510×10/12-14-16-20-25-34-40 |

63×3.5-4.5-5-6-7-8-9-10-12-14 | 203×6-7-10-15-20-25-30 | 530×10/ 12 14 16 18 20 30-40 |

68×4-4.5-5-6-7-8-9-10-12-14-16 | 203×32-36-40 | For larger caliber, please contact the customer manager for communication |

70×4-4.5-5-6-7-8-9-10-12-15-16 | 219×6-8-12-16-18-20-25 |

Strict Product Inspection

1.Chemical Component Analysis

2.Mechanical Properties (Ultimate tensile strength, Yield strength, Elongation)

3.Technical Properties (Flattening Test, Flaring Test, Bending Test, Hardness Test, Blow Test, Impact Test etc)

4.Exterior Size Inspection

5.Nondestructive Test (Ultrasonic flaw detector, Eddy current flaw detector),

6.Hydrostatic Test

Certificate Of ASTM A572 Grade 50 High Strength Low Alloy Pipe

BC1

FACTORY PRODUCTION CONTROL CERTIFICATE,ln compliance with the requirements of BC1:2012 and the Building and Construction Authority, Singapore

EN10210

Manufacture of Hollow Sections :This certificate proves that the performance stability meets the performance of European standards

EN10219

Manufacture of Hollow Sections :This certificate proves that the performance stability meets the performance of European standards

BV

This certficate is issued to attest that Bureau Vveritas Marine & Ofishore has perormed, at the above company's request and in compliance withthe requirements of NR320,a satisfactory assessment of the manudacturing facilities and associated quality procedures related to the ranrge of therecogniition.

ISO14001(GB/T 24001)

ENVIRONMENTAL MANAGEMENT SYSTEM CERTIFICATE

OHSAS 18001(GB/T28001-2011)

OCCUPATIONAL HEALTH AND SAFETYMANAGEMENT SYSTEM CERTIFICATE

ISO9001(GB/T19001)

The production of rectangular pipe and hot-dip galvanized pipe, the sales and service of metal materials, and the quality management system meet the requirements

GB / t19001-2016 / iso9001:2015

JIS G3466

Jis G 3466 : Carbon steel square and rectangular tubes for general structure meet JIS G3466 standard

Maintenance And Care | Tips For Extending The Lifespan Of ASTM A572 Grade 50 Carbon Steel Seamless Pipes

1. Store in a clean and unobstructed area away from factories and mines that produce harmful gases or dust

2. On the site, weeds and all debris should be removed, and thick walled steel pipes should be kept clean.

3. In the warehouse, materials that are corrosive to thick walled steel pipes such as acid, alkali, salt, cement, etc. should not be stacked together to prevent confusion and mutual corrosion.