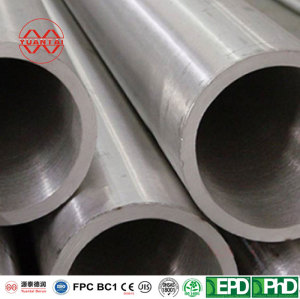

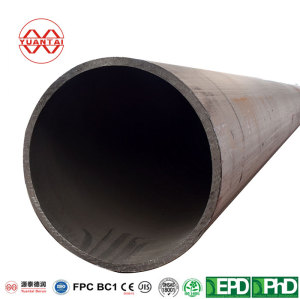

Cold Drawn Seamless Pipe

Review

Description

Premium Cold Drawn Seamless Pipe – Ultra-Precise, High-Strength, for Demanding Industrial Applications

Key Features:

🔹 High Dimensional Accuracy ±0.05mm

🔹 Smooth Surface – No Scaling, Ready to Use

🔹 Enhanced Strength & Hardness

🔹 Materials: 20#, 45#, A106 Gr.B, ST35, ST45.8

🔹 Standards: ASTM A106, GB/T3639, DIN 2391

🔹 Applications: Hydraulic Cylinders, Machinery, Auto Parts

🔹 Custom Cutting, Beveling, Packaging

| CommonSize | OD | 16-457mm |

| Wall Thickness | 2-100mm,Up to 200mm | |

| Length | 6m-12m or as request | |

| Steel material | Q195, Q215, Q235, Fe310, Fe360, St33, St37-2, SS330, SS400, S235, S275, S355, ASTM 1010, ASTM 1017, ASTM 1020 | |

Standard | API,ASTM, ASME, DIN,GB,JIS,ASNI,BS | |

Usage | Transport routes for gas, oil, chemical materials, water,steam and other gas or liquid | |

Ends | Plained or Beveled or other requirements | |

Surface

| Bared, Black Painted, Galvanized, Oiled or to your requirements | |

Package | 1.In bundle with steel strips2.Woven bag packing3.To your requirement | |

Packing | Bundle, or with all kinds of colors PVC or as your requirements | |

Product Description

Our Cold Drawn Seamless Pipe is precision-engineered for applications requiring tight tolerances, superior surface finish, and high mechanical strength. Through a cold drawing process, the pipe achieves exceptional dimensional accuracy, smooth surface (Ra ≤ 1.6μm), and improved tensile strength—up to 20% higher than hot-rolled equivalents. Ideal for hydraulic cylinders, precision shafts, automotive components, and high-pressure machinery, these seamless tubes eliminate weld failure risks and ensure long-term reliability. Made from high-quality carbon steel (20#, 45#, A106 Gr.B), and compliant with ASTM A106, GB/T3639, DIN 2391, our pipes are available in OD 10–200mm, WT 1–20mm. Optional services include cut-to-length, beveled ends, anti-rust oil, and custom packaging. Trusted by global manufacturers for consistent quality and on-time delivery.

Why Choose Us?

✅ Precision Guaranteed – CNC-controlled drawing for consistent dimensions

✅ No Surface Defects – Bright finish, no scale, ready for plating or painting

✅ High Strength-to-Weight Ratio – Stronger than welded tubes, lighter than solid bars

✅ Global Compliance – Certifications: ISO 9001, API Monogram (on request), Mill Test Report

✅ Custom Fabrication – Cut, bevel, drill, or package per your technical drawings

✅ Fast Delivery – 15–25 days for bulk orders, stable production capacity

Applications

⚙️ Hydraulic Systems – Cylinder tubes, piston rods

🏭 Industrial Machinery – Spindles, bearings, transmission shafts

🚗 Automotive – Steering columns, suspension components

🧪 Instrumentation – Precision tubes for sensors & gauges

🔧 Engineering Equipment – High-load connectors & supports

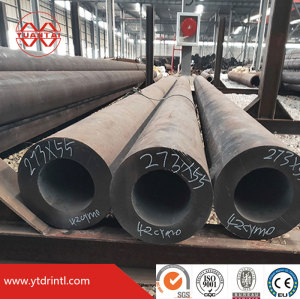

Hot-Rolled Seamless Steel Pipe:

Pipe Blank Preparation and Inspection

Pipe Blank Heating

Perforation

Pipe Rolling

Reheating of Steel Pipe

Sizing or Reducing

Heat Treatment

Straightening of Finished Pipes

Finishing

Inspection - including non-destructive, physical and chemical, and dimensional inspection

Storage

Cold-Rolled (Drawn) Seamless Steel Pipe:

Billet Preparation

Acid Pickling and Lubrication

Cold Rolling or Drawing

Heat Treatment

Straightening

Finishing

Inspection - including non-destructive, physical and chemical, and dimensional inspection

For both types, the final steps involve inspection to ensure the quality of the seamless steel pipes before they are stored.