Custom sharp angle square steel pipe factory Tianjin YuantaiDerun

- Model

- ytdr-313

Item specifics

- Thickness

- On demand customization

- OD

- On demand customization

- length

- On demand customization

- Tolerance

- ±10% or as required

- Grade

- Gr.A,Gr.B,Gr.C,S235,S275,S355,S420,S460,A36,SS400,

- Delivery time

- 7-30 days

- OEM/ODM/OBM

- accept

- Supply capacity

- Annual output of 5 million tons

- Certification

- CE,LEED,BV,PHD&EPD,BC1,EN10210,EN10219,ISO9000,AST

Review

Description

Custom sharp angle square steel pipe factory Tianjin YuantaiDerun

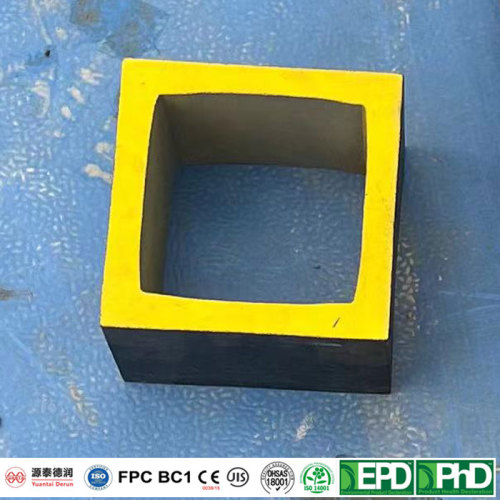

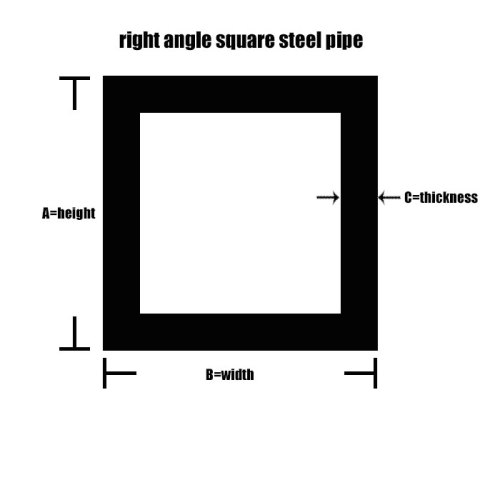

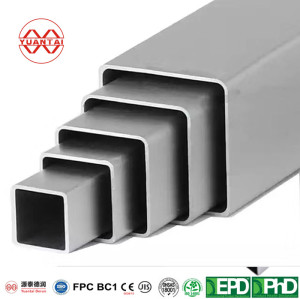

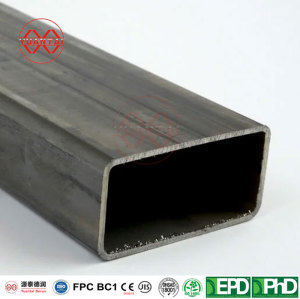

1、 Definition of square steel pipes with sharp corners

The R angle of sharp angle square pipes is different from ordinary circular arc square pipes, and right angle square steel pipes: it is a type of right angle square pipe with an R angle not greater than one time the wall thickness. Right angle square tube: When the wall thickness is not greater than 3mm, the R angle is not greater than 1mm; When the wall thickness is 3-8mm, the R angle should not exceed 2mm; When the wall thickness is above 8mm, R is not greater than 3mm as a sharp corner square tube.

2、 Specification of square steel pipes with sharp corners

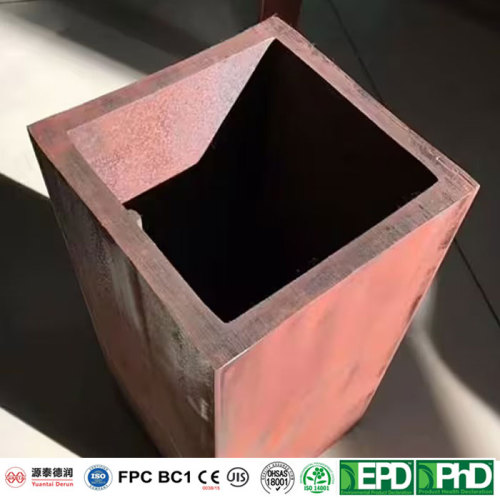

The size range of a right angle square tube is: side length 10mmx10mm~1200mmx1200mm, wall thickness 0.5mm~60mm; Pipe length of 0.5-24M or customized length.

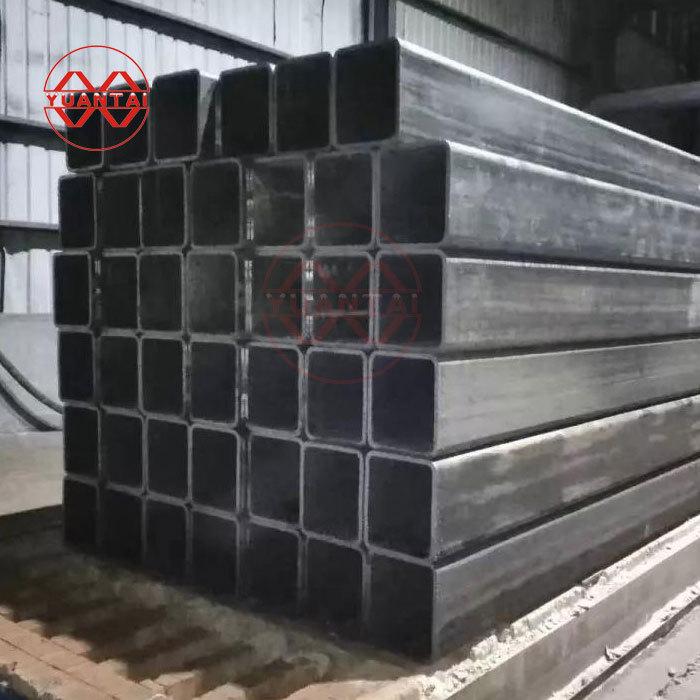

3、 Square steel pipes with sharp corners Process flow

Inspection of round pipe (raw material) - feeding - hydraulic propulsion - roll extrusion (round square change) - Inspection of steel pipe (overall dimension, flatness, perpendicularity and R angle) - blanking (inspection of steel pipe straightness and twist) - shaping of mouth end (there will be deformation area at the head end during steel pipe deformation) - sawing and trimming - Inspection and spraying standard - Warehousing

4. Processing process

The main purpose of the new intelligent tempering furnace equipment of Tianjin yuantaiderun group is to remove the internal stress in the steel pipe. The methods of removing internal stress include natural aging and artificial aging. Natural aging is that the steel pipe is placed in the open field for more than half a year, and it will form slowly, so as to eliminate or reduce the residual stress. There are two methods of artificial prescription:

① Heat treatment to remove internal stress: heat the steel pipe to 550 ~ 650 ℃ for stress relief annealing, which saves time than natural aging and removes residual stress more thoroughly

② Vibration stress relief: in short, it is to eliminate the stress of steel pipe by vibration. VSR is to apply additional alternating stress or deformation to the workpiece by using the resonance of the workpiece. When the additional alternating stress is superimposed with the residual stress and absorbs energy through the internal friction of the material to reach or exceed a certain threshold value of the material, the workpiece will undergo micro or macro viscoelastic plastic mechanical deformation, so as to reduce and homogenize the residual stress in the workpiece and stabilize its dimensional accuracy.

The square rectangular tube after internal stress relief annealing ensures the mechanical properties, especially in the aspects of yield strength, tensile strength, elongation and impact compressive capacity, and realizes the effect of 1 + 1 > 2.

Effect of modified drawing tube annealing heat treatment

Effect of modified drawing tube annealing heat treatment

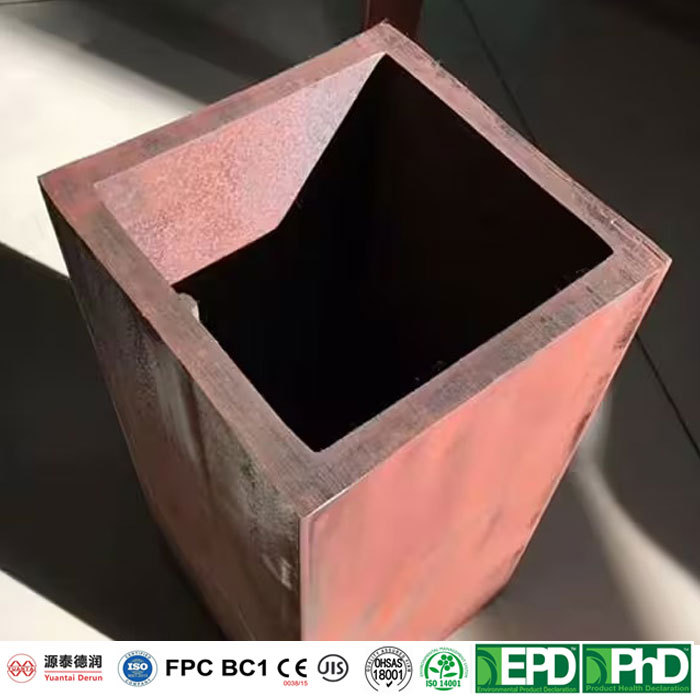

Test distortion of modified drawn pipe

The picture shows the test distortion of modified drawn pipe produced by yuantaiderun after annealing heat treatment

5、 Engineering performance

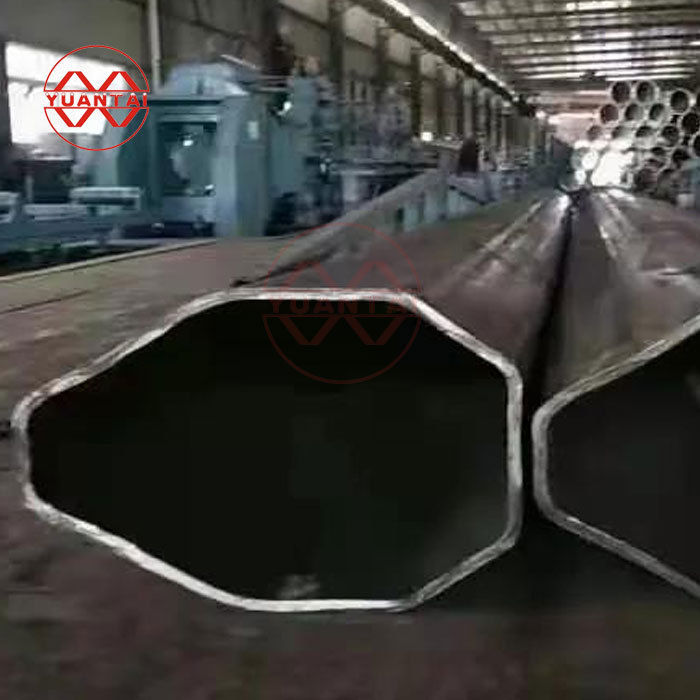

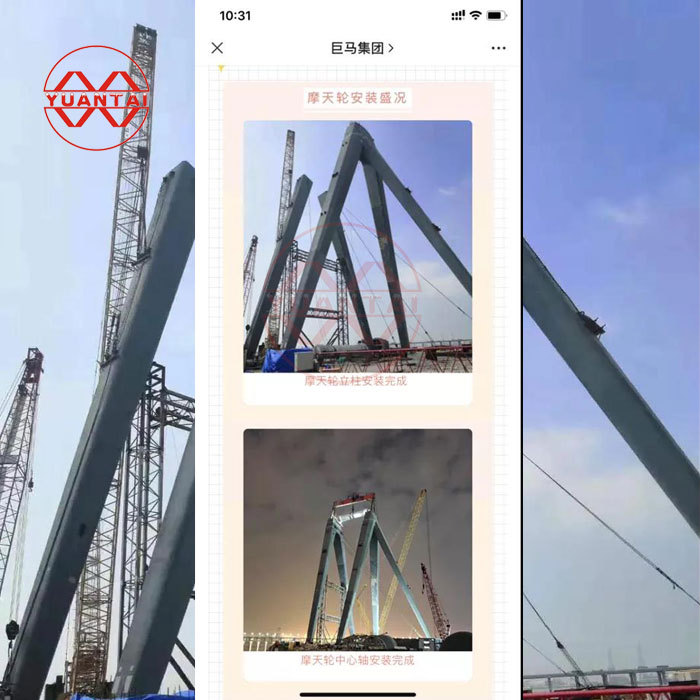

1. The main column of the 128M Ferris wheel of Shenzhen OCT adopts the inclined octagonal tube produced by Yuantai Derun

Oblique octagonal tube

Oblique octagonal tube made dy yuantaiderun

Construction site

Installation of Ferris wheel column completed

Construction site

The installation of the central shaft of the ferris wheel is completed

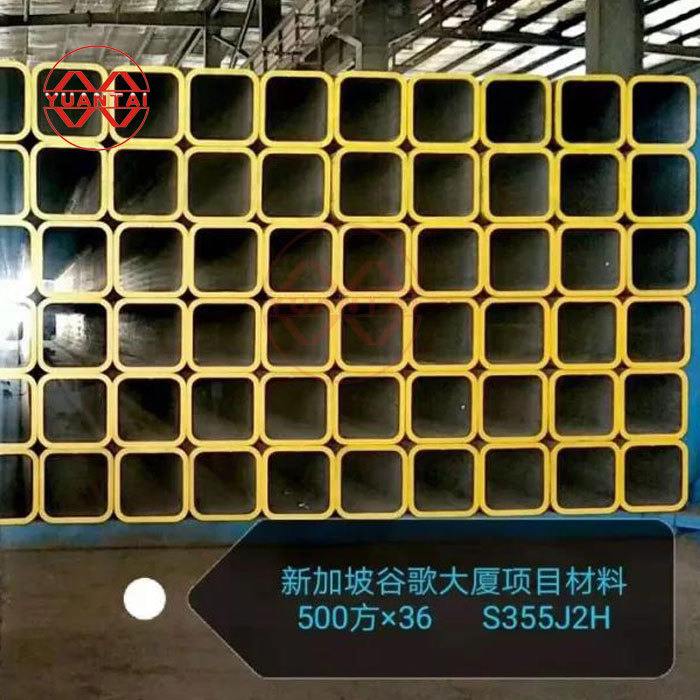

2.The construction of Google tower in Singapore adopts 500mm * 500mm * 36mm modified pipe produced by Yuantai derun, made of s355j2h, with a total of 4000 tons.

Google building Singapore

Singapore Google building

500*500*36 S355J2H

Materials of Google building project in Singapore

3. For the establishment of Sichuan Tianfu airport, 90mm * 250mm * 20MM modified pipe produced by YuantaiDerun is adopted

4. The headquarters of Beijing Chaoyang aiib was established by adopting 500mm * 520mm * 22mm modified pipe produced by Yuantai technology

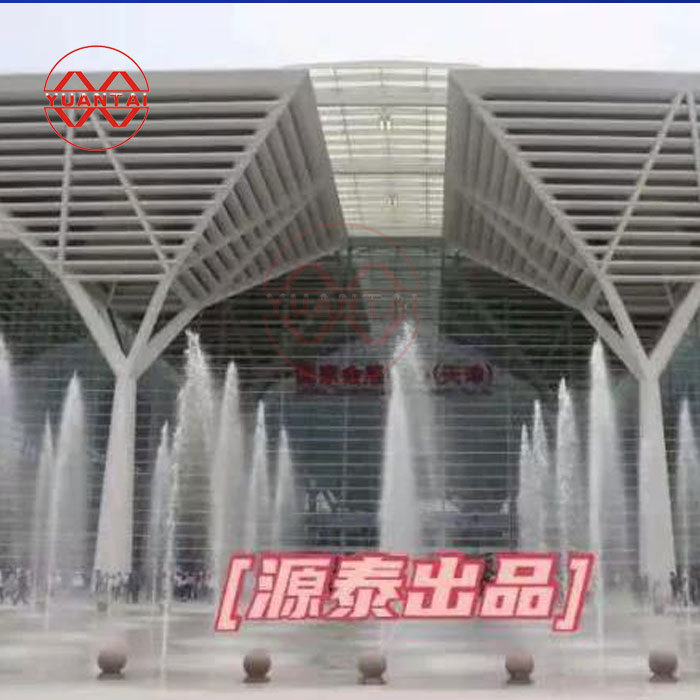

5. National Convention and Exhibition Center (Tianjin) venue

At the "China Building Science Conference and green smart building Expo", the first exhibition of the National Convention and Exhibition Center (Tianjin) held on June 24, 2021, Tianjin yuantaiderun group provided square tube (200) for the construction of the national exhibition × seven hundred × 8mm,200 × seven hundred × 10mm,200 × seven hundred × 12mm,200 × seven hundred × 16mm,200 × eight hundred × 8mm,200 × eight hundred × 10mm,200 × eight hundred × 12mm,200 × eight hundred × 16mm) is mainly used for column structure and supporting structure. The umbrella shaped steel structure of the main body of the main entrance landing Hall of the exhibition hall is made of "yuantaiderun" brand structural steel pipe products.

As we all know, square pipe is a kind of special steel pipe with hollow square section, also known as steel cold-formed profile. In addition to wall thickness thickening, the corner size and edge flatness of hot-rolled extra thick wall square pipe reach or even exceed the level of resistance welding cold-formed square pipe. Tianjin yuantaiderun group welcomes customers to actively consult various special-shaped pipe orders to challenge all kinds of impossibility! Contact Us

6、 Sharp angle square steel pipe material

Domestic standards (GB/T700-2006, GB/T69-2015, GB/T/1591-2018): Q195, Q235B, Q355 (B/C/D), Q420 (B/C/D/E), Q460 (B/C/D/E), 20 #, 45 #, etc.

European Standard (EN10025-1993): S235JR, S235J0, S355J2H, S355JRH, S420, S355J0H, S460NL, S460ML.

American Standard (ASTM A106/A500): Gr.A, Gr.B, Gr.C, Gr.D, Gr50, Gr60, Gr65.

Japanese standard (JIS G3466): SS330, SS400, STK490, etc.

Australian Standard (AS1163): C250, C350, C450, etc.

Indian Standards (IS1161, IS10748, IS 1239 (PART1) -2004, ISI 1544-1962, IS 17876:2012):

7、 Executive standard for square steel pipes with sharp corners

National standards: GB/T6728-2017, GB/T3094-2012

European standards: DIN EN 10210, DIN EN 10219

American standard: ASTM A500

Japanese Standard: JISG 3466

Australian Standard: AS 1163

Stamp: IS1161、IS17876、IS1239

8、 Application of Sharp Corner Square Steel Pipe

The square steel pipes produced by Yuantai Derun are mostly used for mechanical guides, agricultural machinery skeletons, steel and wood furniture, curtain wall construction, large steel structures, mechanical equipment, etc., and have received unanimous praise from customers.

Welcome global buyers of square tubes to come for online and offline consultation and ordering.