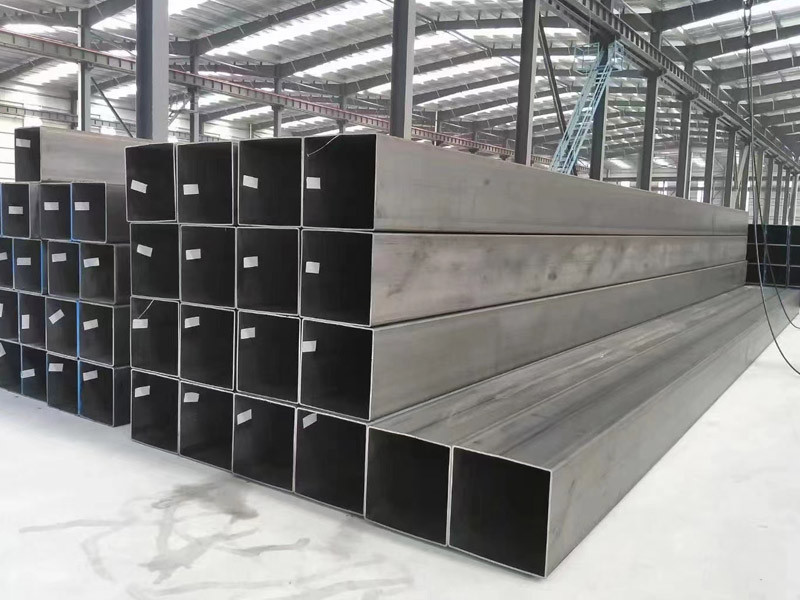

hot rolled steel square tubing

- Model

- hot rolled steel square tubes

Review

Description

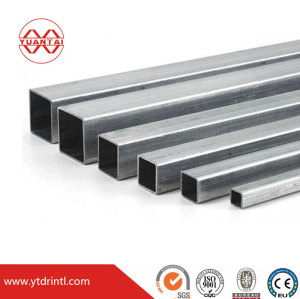

Hot Rolled Steel Square Tubing

Hot rolled steel square tubing is a type of cold formed, electric-resistance welded steel tube or cold formed LSAW/SSAW steel tube. The raw materials for hot-rolled square steel tubes are mostly hot-rolled steel coils or hot-rolled steel plates.

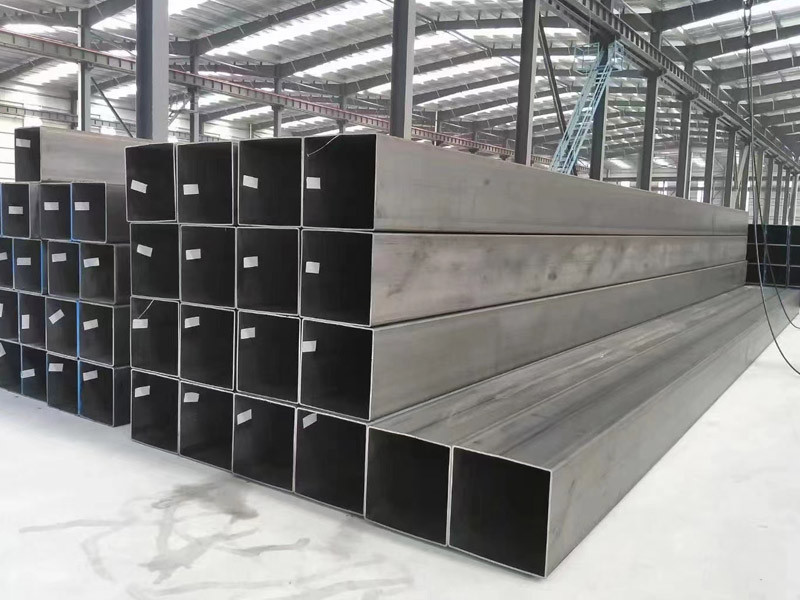

Small diameter hot-rolled steel square tubings are mostly manufactured using the ERW steel tube manufacturing process. In the workshop of Yuantai Derun, we refer to hot-rolled steel square tubings with a diameter below 200 * 200mm as small diameter hot-rolled steel square tubings, and those with an outer diameter greater than 200 * 200mm as large diameter hot-rolled steel square tubes.

Type Of Hot Rolled Steel Square Tubes

Shape Of Hot Rolled Steel Square Tube

Coating Of Hot Rolled Steel Square Tubes

Value Added Services For Other Hot Rolled Steel Square Tubes

Cover All Hot Rolled Steel Square Tube Sizes For You

Standard Size |

Outer Diameter(mm)

|

Wall Thickness(mm)

|

Length(M)

|

Pieces/Bundle

|

|

20*20

|

1.3-2.75

|

0.5-26.5

|

144

|

|

|

25*25

|

1.3-2.75

|

0.5-26.5

|

144

|

|

|

30*30

|

1.3-3.75

|

0.5-26.5

|

100

|

|

38*38 | 1.5-2.75 | 0.5-26.5 | 100 | |

40*40 | 1.3-5.75 | 0.5-26.5 | 100 | |

50*50 | 1.3-7.75 | 0.5-26.5 | 64 | |

60*60 | 1.3-7.75 | 0.5-26.5 | 49 | |

70*70 | 2.0-5.75 | 0.5-26.5 | 36 | |

75*75 | 1.4-7.75 | 0.5-26.5 | 36 | |

80*80 | 1.4-7.75 | 0.5-26.5 | 36 | |

90*90 | 2.0-7.75 | 0.5-26.5 | 25 | |

100*100 | 1.8-5.75 | 0.5-26.5 | 25 | |

100*100 | 5.75-11.75 | 0.5-26.5 | 16 | |

120*120 | 2.5-5.75 | 0.5-26.5 | 16 | |

120*120 | 5.75-11.75 | 0.5-26.5 | 16 | |

140*140 | 2.5-11.75 | 0.5-26.5 | 9 | |

150*150 | 2.5-13.75 | 0.5-26.5 | 9 | |

160*160 | 3.0-11.75 | 0.5-26.5 | 9 | |

180*180 | 3.0-13.75 | 0.5-26.5 | 9 | |

200*200 | 2.75-15.75 | 0.5-26.5 | 4 | |

250*250 | 3.75-15.75 | 0.5-26.5 | 4 | |

300*300 | 4.5-15.75 | 0.5-26.5 | 4 | |

350*350 | 5.5-15.75 | 0.5-26.5 | 1 | |

400*400 | 7.5-15.75 | 0.5-26.5 | 1 | |

450*450 | 7.5-15.75 | 0.5-26.5 | 1 | |

500*500 | 9.5-15.75 | 0.5-26.5 | 1 | |

600*600 | 9.5-50 | 0.5-26.5 | 1 | |

700*700 | 9.5-50 | 0.5-26.5 | 1 | |

800*800 | 9.5-50 | 0.5-26.5 | 1 | |

900*900 | 11.5-50 | 0.5-26.5 | 1 | |

1200*1200 | 20-60 | 0.5-26.5 | 1 |

Not Standard Size |

Outer Diameter(mm)

|

Wall Thickness(mm)

|

Length(M)

|

Pieces/Bundle

|

|

32*32

|

1.3-2.75

|

0.5-26.5

|

100

|

|

|

35*35

|

1.3-3.0

|

0.5-26.5

|

100

|

|

|

45*45

|

1.3-4.75

|

0.5-26.5

|

64

|

|

42*42 | 1.3-3.75 | 0.5-26.5 | 100 | |

55*55 | 1.3-5.75 | 0.5-26.5 | 64 | |

125*125 | 2.5-11.75 | 0.5-26.5 | 16 | |

127*127 | 2.5-11.75 | 0.5-26.5 | 16 | |

130*130 | 2.5-9.75 | 0.5-26.5 | 9 | |

135*135 | 3.0-11.75 | 0.5-26.5 | 9 | |

220*220 | 3.75-11.75 | 0.5-26.5 | 4 | |

240*240 | 4.75-11.75 | 0.5-26.5 | 4 | |

280*280 | 4.5-11.75 | 0.5-26.5 | 4 | |

310*310 | 4.5-12.5 | 0.5-26.5 | 4 | |

420*420 | 7.5-40 | 0.5-26.5 | 1 | |

510* 510 | 9.5-40 | 0.5-26.5 | 1 | |

640x 640 | 9.5-50 | 0.5-26.5 | 1 | |

810*810 | 9.5-50 | 0.5-26.5 | 1 | |

1200*1200 | 20-60 | 0.5-26.5 | 1 |

Hot Rolled Steel Square Tubing Manufacturing Process -ERW

Hot rolled steel square tubing manufacturing process(DFT Directly Forming Technology):

Uncoiling - "Leveling - "Shear Butt Welding - "Disc Shearing - "Loose Sleeve Storage - "Roll Forming - "High Frequency Welding - "Deburring - "Water Cooling - "Shaping - "Flaw Detection - "Cutting - "Paint and Anti-Rust - "Inspection - "Spraying Labeling - "Packing and Storage

Hot Rolled Steel Square Tubes Manufacturing Process -LSAW

Hot Rolled Steel square tube manufacturing process(LSAW JCOE):

Steel plate inspection - Trimming - Pre bending - Cold Forming - Double sided submerged arc welding - Sizing - UT Detection -Spraying Labeling - Packing and Storage.

Part Two:

Round JCOE Tubes - Round To Square Tubes Production Line-Square Tube Testing-Storage.

Strict Hot Rolled Steel Square Tubing Testing

CNAS Certification Testing Center VS. Unknown Small Factory False Test Report

Traceable Raw Materials From Large Brand Factories VS. Raw Materials From Small Workshops With Unknown Sources

High Performance Hot-Rolled Steel Square Tubes VS. Ordinary Square Tubes With Unsatisfactory Performance

Hot Rolled Steel Square Tubing Products Have Passed Multiple Global Authoritative Certifications

22 Years Of Hot Rolled Steel Tubing Manufacturing Experience

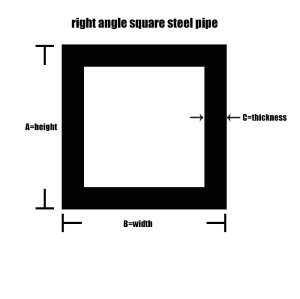

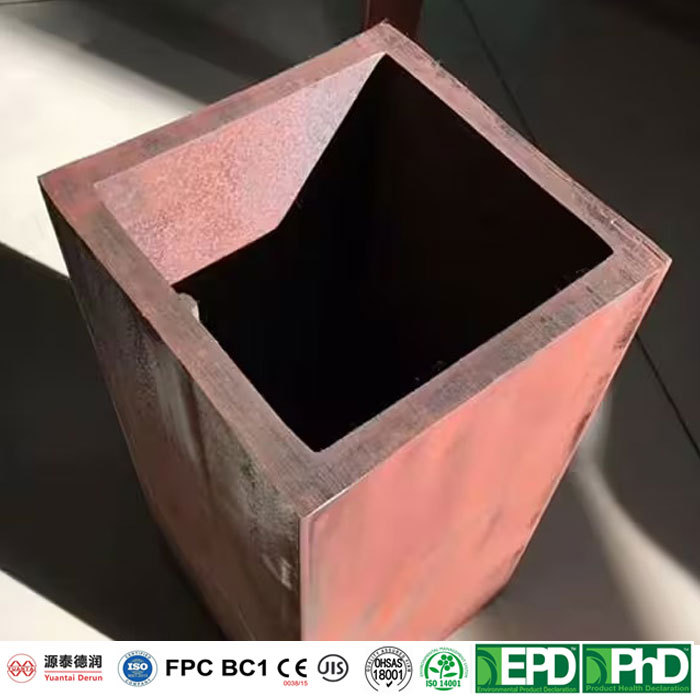

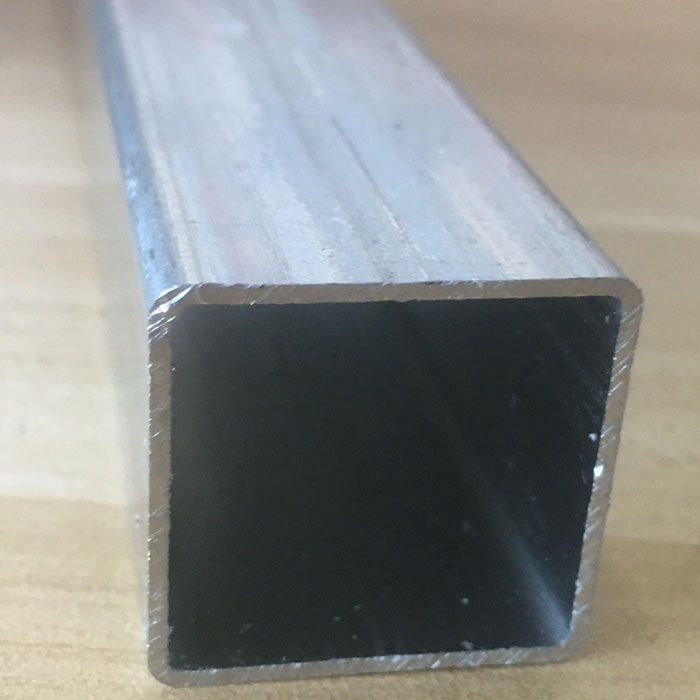

Features

right angled edges

flat surfaces

precise dimensions

high strength

corrosion resistance

Good Weld

Video

Application

Packaging And Shipping

Fast And Safe

After-sales Guarantee

- By default the hot rolled steel square tubes from Yuantai Derun will have a 90-day warranty period from the time the customer receives the goods and accepts them.

- Once quality issues are discovered, you can immediately contact our customer manager for after-sales treatment.

- Any other questions, welcome to send us email.